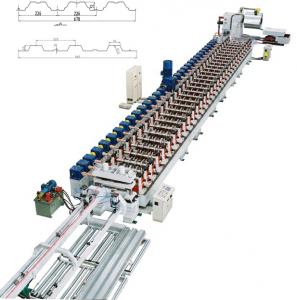

Quality of electric rolling door machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Classification of electric rolling door

First, on the basis of the door sheet material of electric rolling door can be divided into: European style rolling shutter door, inorganic cloth diagram type,mesh type, aluminum alloy door and the crystal rolling door.

Second, from the electric rolling shutter door special motor types: special for rolling shutter door motor: fireproof rolling door machine, Aus rolling door machine, plug door rolling machine, tubular door rolling machine, inorganicdouble curtain rolling door machine, rapid roll door machine. Electric rolling door uses different kinds of special motor each have their own characteristics,Tianjin Unicom door also can be customized according to customer demand.

Third, the electric rolling door uses also divides a lot of kinds: according to different uses of every user, a silent type, noise reduction, a stainless steel shutter doors, fire shutter doors and wind, and the crystal rolling door.

The installation method of electric rolling door

First, in the first need to install the mouth frame position draw reference line.Indicate the size, and then find the Tianjin Unicom door staff to design the proper electric shutter doors, one point to note here is the frame height than the height of the doors to a little high.

Second, the electric rolling door door frame is fixed, the fixing plate here firstremove the lower part of the door frame. Http://www.gliderol-asia.com/

Note: the hole should be reserved grooves on both sides of the ground, the well calibrated, fixed wedge, door iron feet and embedded iron parts welding.Fine stone concrete impaction with cement mortar or strength of not less than 10MPa of the firm.

Third, the main door installation. We must ensure the electric rolling shutter door and the wall to form a whole, closed to do, then paint the hole and wall.After the completion of the painting, the door should be smooth, open the electric rolling shutter door should be free of light, not too tight, too loose orrebound phenomenon.

1 safety precautions:

- door rolling machine by the professional installation, maintenance, must have a good grounding protection, otherwise it may cause personal safety;

- rolling door when the machine is running, the door is prohibited under thestand or pass, curtain below without obstacles;

- regular check door body activities section, ensure the operation will not behindered, maintain lubrication, run the sound normal, otherwise it may causethe personal safety and the influence on the service life.

2 installation and debugging:

- the products according to the right installation scheme of manufacturing(from interior toward the door to see if needed), left installation, the brake shellscrew loosening 4 M5, then the rotating shell 180 DEG re balance locking, and the button switch on the white, green line switch connection;

- door rolling machine should be installed horizontally, reel should be level,concentric, curtain lifting without delay card;

- the transmission chain adjustment: first adjustable fixing bolt loose M6bracket board a small chain wheel, and then adjust the 2 bolts M8 door rolling machine on the transmission, so that the transmission chain sag is 3-6mm (notloaded door front adjustment), then tighten the 3 legs of the nut M10;

- curtain upper and lower stroke adjustment: test machine before unscrewing the limit on the slider 2 fastening screws, the curtain rises to a certain height,rotating the upstream limit screw sleeve contact pressure to the microswitch,hear "Di Da" sound and tighten the screws; then the curtain fell to the ground,with the same determination method the downside of limiting screw sleeve position, the last finger tighten the 2 fastening screws.

3 the use of notes:

- door rolling machine for short-term work system, continuous operation time shall not exceed 7 minutes;

- door rolling machine run by remote control or on the button of "Shang" and "Xia" and "stop" control. According to the "on" "next" button, if no upward or downward movement, must immediately press the "stop" button to cut off the power supply, to avoid burning motor;

- when the power is off, the use of hand zipper up curtain, forbidden exceedhas certain height, so as not to damage the limit switch, causing the race to the top; close the curtain, can pull the light manual pull rod, so that the curtainuniform fall, when the curtain will be fully closed, loosen the tie rod, and thenagain to the fully closed, to prevent damage limit switch;

The occurrence of lightning - weather, as far as possible to disconnect thepower supply;

- use the door rolling machine, the operation personnel shall not leave the scene, the abnormal situation should immediately cut off the power, can thenuse the rear troubleshooting.

- Q: What is the roll forming machine?

- The elliptical rolling machine is composed of a rolling device, a rolling pan, a transmission and a brake device, a base, a spindle assembly, a die seat elliptical movement device, a rolling head seat, an electric motor and an electrical control system

- Q: How is the molding machine installed?

- 1 check the machine in the transport process is damaged or deformation;

- Q: How to maintain the molding machine?

- 1 Check the host before driving is complete, than with loose and electrical loose, electrical grounding is good.

Send your message to us

Quality of electric rolling door machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords