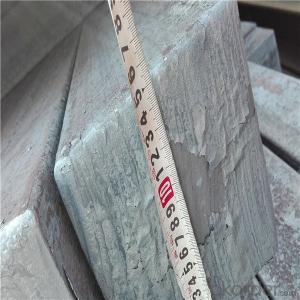

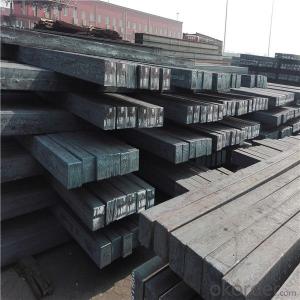

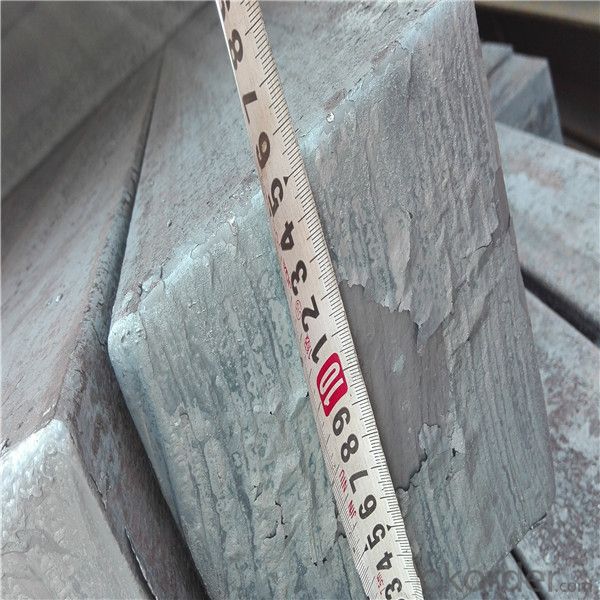

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still

require a series of shaping and molding procedures such as hot and cold working, milling and cutting

before they are sold in hardware stores, or used for different applications. The unformed billets,

however, can be used in striking currency such as coins and as reserves, similar to gold bars.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

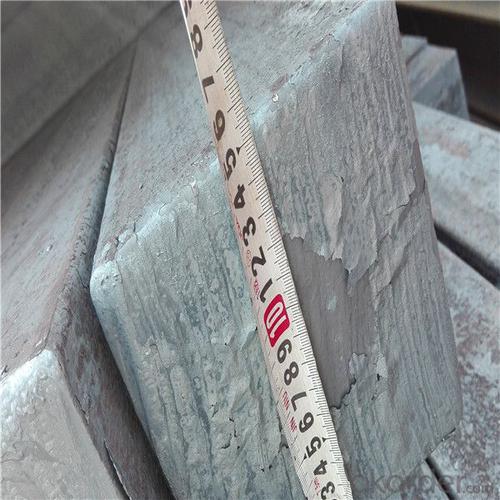

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

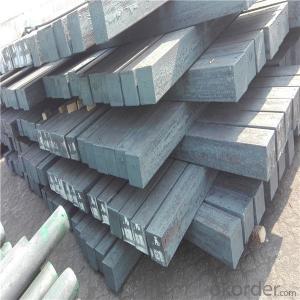

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: Are steel billets used in the manufacturing of construction machinery?

- Yes, steel billets are commonly used in the manufacturing of construction machinery. Steel billets are semi-finished products that are used as raw materials in various industries, including construction machinery manufacturing. These billets are typically made from molten steel that is cast into a solid form and then further processed to shape and size. Due to their high strength, durability, and versatility, steel billets are ideal for constructing heavy-duty components and structures in construction machinery. They can be used to manufacture various parts such as chassis, frames, buckets, booms, and arms, among others. The use of steel billets ensures that construction machinery is capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: What are the different methods of steel billet cooling?

- There are several different methods of steel billet cooling that are commonly used in the steel industry. These methods include air cooling, water cooling, and controlled cooling processes. One method of cooling steel billets is through air cooling. This involves allowing the billets to cool naturally in ambient air, without any additional cooling mechanisms. Air cooling is a simple and cost-effective method, but it may result in slower cooling rates and less controlled cooling conditions compared to other methods. Water cooling is another common method used to cool steel billets. This involves immersing the billets in water or spraying them with water to accelerate the cooling process. Water cooling provides more efficient and controlled cooling rates compared to air cooling. It allows for faster cooling and can help achieve desired material properties, such as increased hardness or improved microstructure. Controlled cooling processes are a more advanced method used to cool steel billets. These processes involve precise control of temperature and cooling rates to achieve specific material properties. One such process is known as quenching, which involves rapid cooling of the billets in a controlled medium, such as oil or water, to achieve a desired hardness. Another controlled cooling process is known as annealing, which involves slowly cooling the billets to relieve internal stresses and improve their machinability. In addition to these methods, there are also specialized cooling techniques, such as spray cooling and water mist cooling, that are used in specific applications or industries. These methods involve spraying a fine mist of water onto the billets to achieve rapid and uniform cooling. Overall, the choice of cooling method depends on various factors, such as the desired material properties, production requirements, and cost considerations. Different cooling methods offer different benefits and trade-offs, and it is important for steel manufacturers to select the most suitable method for their specific needs.

- Q: How are steel billets used in the production of agricultural vehicles?

- Steel billets are used in the production of agricultural vehicles as they serve as the raw material for various components and parts. These billets are heated and then formed into desired shapes using processes like forging or casting. They are used to manufacture key structural components such as chassis, axles, and frames, providing the necessary strength and durability for heavy-duty applications in agricultural vehicles.

- Q: What are the different grades of steel used for producing billets?

- The different grades of steel used for producing billets vary depending on the specific requirements and applications. Some common grades include mild steel, low carbon steel, medium carbon steel, high carbon steel, alloy steel, and stainless steel. Each grade offers different mechanical properties, such as strength, durability, and corrosion resistance, to meet the desired characteristics for the final product.

- Q: What is the role of steel billets in the construction of commercial buildings?

- The primary raw material used in manufacturing structural steel sections for commercial buildings is steel billets, which play a crucial role in the construction process. These sections, such as I-beams, H-beams, channels, angles, and plates, are created by melting and casting steel billets into various shapes and sizes. Once fabricated, welded, and assembled, these sections form the framework, columns, beams, and other load-bearing elements of the building. Steel is an ideal material for commercial buildings due to its high strength and durability. It can withstand heavy loads, resist deformation, and provide structural integrity. Additionally, steel billets are commonly used to produce long steel bars or rods, which serve as reinforcement in concrete structures. This combination of concrete and steel, known as reinforced concrete, offers both compressive strength and tensile strength, making it widely used in commercial buildings. Furthermore, steel billets are essential for providing stability and support to the overall structure. They help evenly distribute weight and loads throughout the building, ensuring the safety and integrity of the construction. Steel is also highly fire-resistant, reducing the risk of damage in the event of a fire and enhancing the overall safety of the building. In addition to their functional benefits, steel billets offer design flexibility and cost-effectiveness. They can be easily customized and fabricated to meet the specific requirements of the building design, allowing architects and engineers to create innovative and efficient structures. Moreover, steel structures are lightweight compared to traditional construction materials, potentially reducing construction costs by lowering the overall weight of the building. In conclusion, steel billets are essential in the construction of commercial buildings, providing the necessary strength, durability, stability, and fire-resistance required for the structural framework. Their versatility, cost-effectiveness, and design flexibility make them a preferred choice for architects, engineers, and contractors in the construction industry.

- Q: What is the standard size of a steel billet?

- The standard size of a steel billet can vary depending on its intended use and industry standards. However, common sizes range from 5 inches by 5 inches to 10 inches by 10 inches, with varying lengths.

- Q: Can steel billets be used in the production of electrical components?

- Indeed, the utilization of steel billets in the manufacturing of electrical components is possible. Steel billets, which are considered as intermediate products, are commonly employed in the creation of diverse steel goods, including electrical components. Steel, known for its adaptability, exhibits exceptional strength, durability, and electrical conductivity, rendering it appropriate for electrical applications. Steel billets can undergo further processing and shaping, such as being transformed into bars, rods, or sheets. Subsequently, these forms can be utilized in the production of electrical components like connectors, terminals, wires, and cables. Moreover, steel can undergo coating or plating with other materials to heighten its conductivity or provide resistance against corrosion, thereby further increasing its suitability for the manufacturing of electrical components.

- Q: How are steel billets cut into smaller pieces?

- Steel billets are typically cut into smaller pieces through a process called sawing or shearing. There are various methods used to achieve this, depending on the desired size and precision of the cuts. One common method is using a saw blade, either circular or band saws, which are specifically designed for cutting through metal. These saws can be manually operated or automated, depending on the scale of the operation. The billets are clamped securely to prevent movement, and the saw blade is guided along the marked cutting line, gradually slicing through the steel to create smaller pieces. Another approach is shearing, which involves using a shear machine to apply intense force to cut through the billet. This method is often used for thicker billets or when precise cuts are not necessary. The shear machine consists of a fixed blade and a moving blade that come together to sever the billet along the desired cutting line. Additionally, advanced technologies like laser cutting or plasma cutting can also be employed to cut steel billets into smaller pieces. These methods utilize high-powered lasers or plasma jets to melt or vaporize the material along the cutting line, resulting in a clean and precise cut. Overall, the choice of cutting method depends on factors such as the thickness of the billet, the desired precision of the cuts, and the production capacity. Regardless of the method used, safety precautions are always taken to ensure the well-being of the operators and to maintain the quality of the cut steel pieces.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The magnetic properties of steel billets are impacted by three key factors: composition, microstructure, and processing conditions. To begin, the composition of the steel billet plays a crucial role in determining its magnetic properties. The inclusion of specific alloying elements like nickel, cobalt, and manganese can enhance the magnetic characteristics of the steel. These elements align the magnetic domains within the steel, leading to increased magnetization and improved magnetic properties. Next, the microstructure of the steel billet influences its magnetic behavior. Factors such as grain size, crystal structure, and the presence of defects or impurities can all affect the magnetic properties of the material. Smaller grain sizes tend to exhibit superior magnetic properties due to better alignment of the magnetic domains. Furthermore, a single-phase crystal structure generally possesses greater magnetism compared to a multi-phase structure. Lastly, the processing conditions employed during the production of steel billets can impact their magnetic properties. Variables such as temperature, cooling rate, and mechanical deformation can all affect the microstructure and consequently, the magnetic behavior. For instance, rapid cooling can result in finer grain sizes and improved magnetic properties. Similarly, mechanical deformation can induce magnetic anisotropy, aligning the steel billet in a specific direction and enhancing its magnetic orientation. In conclusion, the magnetic properties of steel billets are primarily influenced by their composition, microstructure, and processing conditions. By effectively managing these factors, manufacturers can customize the magnetic properties of steel billets to meet the specific requirements of various applications, including electrical transformers, motors, and magnetic sensors.

- Q: What are the different surface treatments for rust prevention in steel billets?

- There are several surface treatments commonly used for rust prevention in steel billets. These include hot-dip galvanizing, electroplating, painting, and applying protective coatings such as zinc-rich primers or epoxy coatings. Each treatment offers varying levels of protection, with hot-dip galvanizing typically being the most effective and durable option.

Send your message to us

Q275 Square Steel Billets factory sale directly

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords