PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

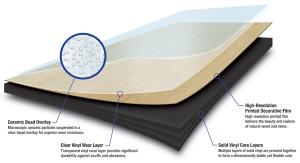

Vinyl Flooring, a plastic Carpet is one of the carpets. It is loom woven with plastic. The raw material contains Polyvinyl chloride resins, plasticizers and other auxiliary materials, by high melting, evenly mixed and molding. It enjoys the characteristics of soft, colorful, comfort, non-flammable, and self-extinguishing, not afraid of wet; do not eat by moth, mildew, and good elasticity, wear-resisting. Plastic carpet can be arbitrary combination when installing. It can be washing out as well.

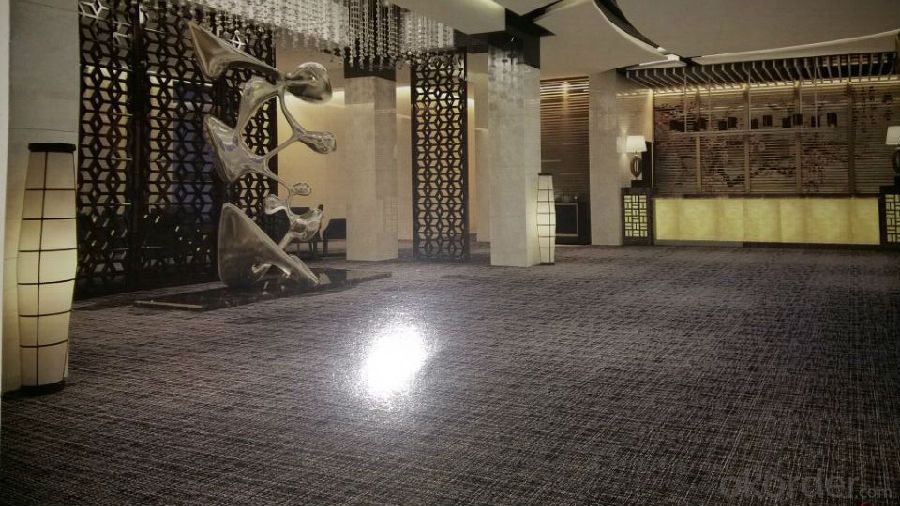

Plastic carpet is suitable for hotels, shopping malls, stage, housing, can also be used for bathroom for anti-skid effect.

2. Features of PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

1 Oil-Proof, wear resistant

2 Aging Last, stable dimension

3 Anti-Abration,enviroment friendly

4 Easy to clean

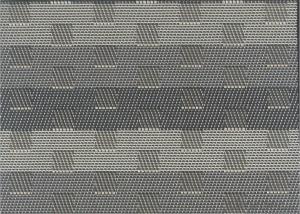

5.Simple pattern on woven PVC carpet, woven Vinyl floor mat

3. Specifications of PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

Material | Surface: pvc coated polyester Backing:pvc |

Style | European style |

Design | woven flooring |

| Width | 1.4-1.9m |

| Thicknes | 2.5-4mm |

Use | Home, Hotel, Bedroom, Outdoor, Decorative, Bathroom |

Size | According to the customer |

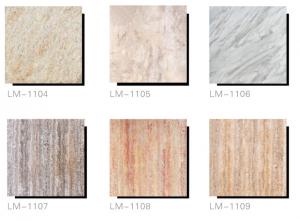

4. Photos of PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

5. FAQ

1) Where it could be applicated?

It is suitable for hotels, shopping malls, stage, housing, can also be used for bathroom for anti-skid effect.

2) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

3) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

4) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

5) Is it fire proof?

Compared with the plastic flooring, plastic carpet is poor flame resistance. It generally is flammable, some still have smol deringphenomenon, namely no flame combustion phenomenon, and it tends to cause fire spreading, caused the fire. With flame retarding, some plastic carpet can be flame resistance.

- Q: Plastic floor can be used indoors

- Compared with wood plastic floor: 1, fireproof performance, flame spread, anti burning cigarette burns; 2, surface hardness, scratch resistant properties than wood; 3, not easy to deformation, good dimensional stability; 4, pattern design, decorative effect, pattern selection is better than the floor; 5, with better performance, can heat welding processing, so that the seam is achieved completely waterproof, dustproof, waterproof, anti bacteria, mildew, moth effect; 6, the noise is small, can be reduced by 6-14 dB, more conducive to noise control when walking; 7, wide application range, not only suitable for Home Furnishing is also suitable for the local flow in many public places and others

- Q: Composite floor plastic sheeting down the impact of heat

- It's about the thickness of the 2mm, with the common "plastic cloth" is not the same thing.

- Q: What is the role of the floor mat plastic sheeting

- You should say that it is a composite floor, his role is mainly moisture, as well as the role of leveling

- Q: Plastic floor how to taste?

- If there is oil or other stains on the surface, you can use a toothbrush dipped in a small amount of toothpaste, gently brush stains

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Hello landlord! Select the plastic floor must choose the site dedicated, the wrong choice of use and material life, you know! There are many types of plastic floor, mainly divided into coil and sheet, is the most common material, plastic sheet flooring series of thousands of species, like the current popular commercial floor: PVC floor (such as shopping mall (supermarket), hotel, hotel, hospital, school, kindergarten, family, office, commercial airport... Site

- Q: How to spread the plastic floor?

- With multi-layer solid wood board paved on the floor tile on the line, it is worth noting that the plastic plate is flat buckle

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- The shortcomings of the plastic floor: the laying of the floor construction requirements will be higher, to consider the floor, environment and other factors, some of the higher technical content

- Q: PVC plastic flooring should be how to pave the road, want to shop this floor, but do not know PVC plastic floor price per square meter of stone? Tell me what the trouble!

- Due to the thickness of the PVC plastic floor is only about 3mm without self bearing capacity, so the ground floor of the high requirements. The technical specifications and performance of this product and the basis of the construction of this product on the ground floor, and the development of standards for the detection of regulations. , 1 humidity: floor based moisture content should be less than 5%, keep the surface dry before construction. 2, surface hardness: 3, fast cutting surface roughness without a trace file or groove surface with a sharp chisel: 2 m straightedge inspection, voids should be less than 2mm. 4 crack: the ground crack width is less than 1.5mm. 5, surface density: the surface must not be too rough, not too many pores, to clean the floor. 6, surface cleanliness: oil, wax, paint, pigment and other residual material must be removed.

- Q: What are the main construction process of laying plastic floor

- Construction pointsGrassroots should reach the surface not sand, not skin, not grey, no hollowing, no grease. Touch without roughness. If the requirements are not met, the ground should be treated first.The positioning line pop-up perpendicular to each other, and according to the laying of parquet patterns.The back surface of the base plate and the plastic floor plate is coated at the same time, and the adhesive surface can be posted when the adhesive surface is not sticky.The bulk of each with a piece of, will more than rubber extrusion in a timely manner with clean cotton silk.Paving is completed, it is necessary to promptly clean the floor surface, the use of water-based adhesives can be wiped with a damp cloth, the use of solvent based adhesives, the use of turpentine or gasoline to wipe the gel marks

- Q: Shop: composite floor below the moisture with plastic mold moisture do?

- The second is ground mat. The mat is composed of a layer of plastic film and polyethylene foam bonding, and this layer of film thickness and toughness of the material is very good, is not an ordinary plastic film, so I know if the laying of the floor directly on the ground, direct contact is no problem, the moisture in the floor around the room floor expansion joint direct release, so there is no problem of ventilation, also to cushion the plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor is used in the material, do not believe you can ask it to. Laying on the ground, a damp proof and moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant

Send your message to us

PVC Woven Vinyl Floor ECO PVC Woven Flooring/Carpet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords