PVC Ceiling Edge Trim Laminated Gypsum Ceiling/PVC Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m³

- Supply Capability:

- 3000000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Gypsum fiber board, also known as calcium silicate board, is a porous material with good insulation,

thermal insulation performance. When the indoor air is humid it can attract water molecules; when the

air is dry, it can release water molecules to adjust the indoor humidity and increase comfort

Product Advantages:

1.Strong aluminum frame and hardware

2.Available in ceiling maintenance panel

3.White powder-coated finish

4.With sealing strips between inner and outer frames

5.Special spring fixed for inner and outer frames, with easy and comfortable control

handles

Main Product Features:

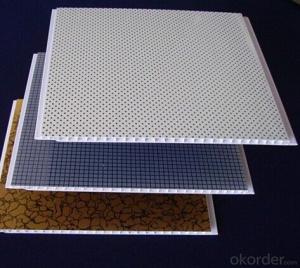

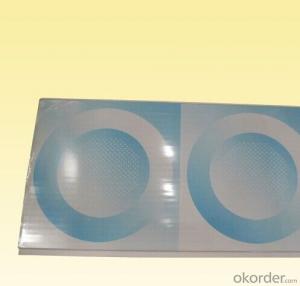

Material: Gypsum Board, non asbestos, sulfate free

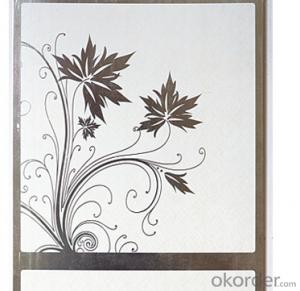

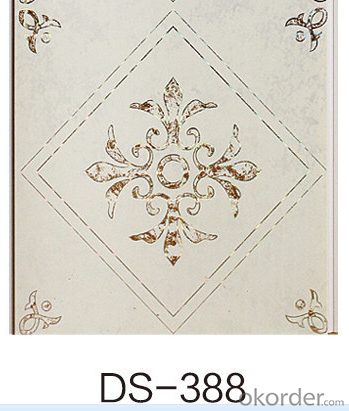

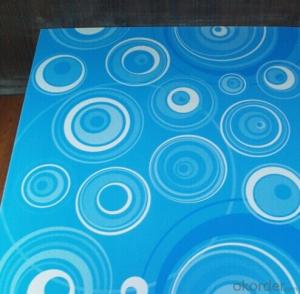

Surface: High quality PVC/Vinyl

Backside: High quality aluminized PET foil

Edges: Square

Weight /cbm: 780kgs/m3

Tolerance: Length: ± 1.0mm, Width: ± 1.0mm,

Thickness: ± 0.5mm

NRC: 0.1 - 0.3

picture

FAQ

· Can we make an OEM order?

o We can offer or supply goods as customers' requirements.

· How can I get some samples? Free or not?

o We can send some normal samples, absolutely free.

· How does your factory do regarding quality control?

o "Quality is priority." We always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISO9001 , SGS authentication, CE for Europe, etc.

- Q: Soft pvc board how to install it? How is the market price?

- Pvc board ceiling construction construction process: the process of grass-roots clean → → → installation of hanging bar → installation of the main keel → installation of the keel → weak, integrated wiring laying → hidden inspection → installation of the keel and PVC board → finished product protection → sub-

- Q: Pvc board in the outdoor high temperature with what glue is good

- Pvc board in the outdoor high temperature can be used HY-108AB glue bonding, the highest resistance to 200 degrees.

- Q: Allow phonetic typing Pvc panel market now how to? Want to do the next trade. Please help me find this station?

- your question is total garble what are you looking for ? try your search bar and learn to make a complete question

- Q: Density board and PVC which expensive

- Normal is PVC expensive, but here there are many limited conditions There are many kinds of PVC, MDF there are many kinds, such as thickness, density and so on High density board general prices are relatively high, and low formaldehyde content of the floor price higher, such as to reach the E0 level So there are specific problems specific analysis

- Q: Pvc soft glass poisonous?

- Generally not toxic, different manufacturers of different materials.

- Q: Ordinary PVC board can be posted wallpaper? Or paint is mainly to improve its appearance

- Can be posted wallpaper, but posted bad words, a long time will be bubbling ~ ~ This is the point of technology and careful Di tick.

- Q: Korea pvc floor ok?

- LG is now basically the domestic OEM but still better than the average domestic

- Q: What is the difference between PVC board and oak board?

- PVC is a kind of plastic composite sheet, waterproof performance is good, cheap, easy to cut, the use of a very wide range of oak is a kind of wood material, waterproof performance is better, mainly harder than PVC, texture is good, but the price is Much more expensive than PVC, oak bathroom cabinet grade are generally higher.

- Q: Is PVC material discolored? Decoration with PVC skirting board will have any problems?

- The two are basically able to use, there will be no problem. Only individual manufacturers shoddy, harm the consumer's products are not among them.

- Q: Pvc board how much a kg

- Pvc KG number of calculation method: plate length x plate width x sheet thickness x sheet weight = KG value

Send your message to us

PVC Ceiling Edge Trim Laminated Gypsum Ceiling/PVC Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m³

- Supply Capability:

- 3000000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords