PVC Foam Sheets In Plastic Sheets PVC Marble Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

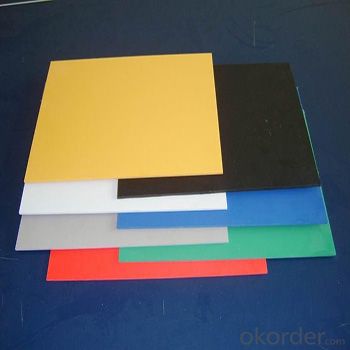

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

Product Specification

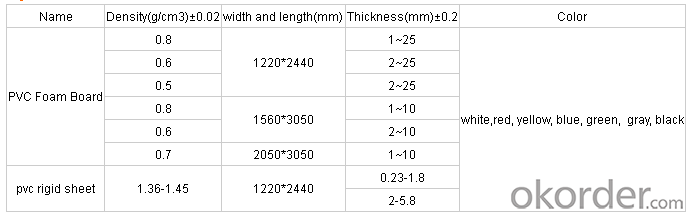

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4) Easy to clean and maintain.

(5) Environmental- friendly green and lead-free.

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

FAQ

1,How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect

2,Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

Product details

- Q: Are plastic sheets resistant to chemicals?

- Yes, plastic sheets are generally resistant to chemicals.

- Q: Can plastic sheets be used for vacuum forming in the aerospace industry?

- Yes, plastic sheets can be used for vacuum forming in the aerospace industry. Vacuum forming is a widely used manufacturing process in aerospace for creating lightweight and complex shapes. Plastic sheets, such as thermoplastics, are heated and then molded over a pattern or mold using vacuum pressure. These formed plastic parts can be used for various applications in the aerospace industry, including interior components, aircraft panels, and even some structural parts.

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wet the cloth with a dusterFind a relatively soft cloth at home and then wet again from top to bottom to scrub again, this will not cause damage to the plastic plate, cleaning can be assured, if you have time to periodic cleaning.

- Q: We are using this for a slip and slide at a camp and need some plastic that is sturdy and will withstand many kids going down it. 6 mil is the minimum, but 8 to 10 mil is prefered and it needs to be about 40 ft x 100 ft. We'd prefer no black, as it will be super hot in the sun. I have already called a few local farm stores, Lowes, and Home Depot. Are there any places that I may have forgotten?

- 10 Mil Plastic Sheeting

- Q: Are plastic sheets resistant to breakage?

- Yes, plastic sheets are generally resistant to breakage due to their flexible and durable nature. However, the level of break resistance may vary depending on the type and thickness of the plastic sheet.

- Q: Are plastic sheets UV resistant?

- Yes, plastic sheets can be made UV resistant by incorporating additives such as UV stabilizers during the manufacturing process.

- Q: Can plastic sheets be used for packaging materials?

- Yes, plastic sheets can be used as packaging materials. They are commonly used in various industries for packaging products due to their durability, flexibility, and ability to protect against moisture and contamination. Plastic sheets can be molded or formed into different shapes and sizes to accommodate various packaging needs.

- Q: I had a plastic bag in which bed sheets came and it disintegrated in my closet. How could this happen?

- Some low-quality plastic/rubber degrades quickly. It wasn't meant to last long.. they probably didn't expect you to keep it.

- Q: February 11, 2003: On Tuesday, less than 24 hours after U.S. Fire Administrator David Paulison described a list of useful items, stores in the greater Washington, D.C

- i recognize duct tape is powerful for just about something. Do you relatively have faith that duct tape and plastic is going to maintain you from radiation or the like? our homes are incredibly meant to breath. for this reason, taping each little thing and plastic ought to no longer help for my area. in line with danger its to make the citizen sense secure.

- Q: Can plastic sheets be used for electrical insulation?

- Yes, plastic sheets can be used for electrical insulation.

Send your message to us

PVC Foam Sheets In Plastic Sheets PVC Marble Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords