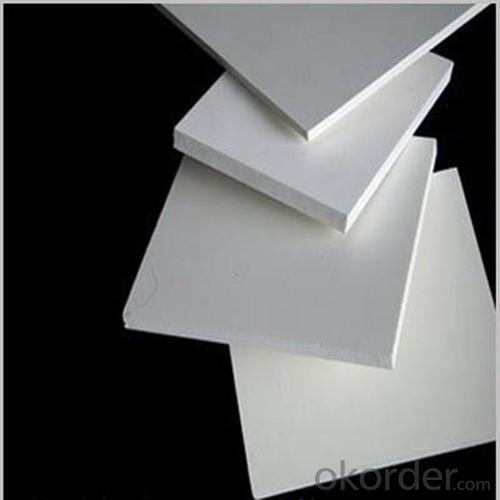

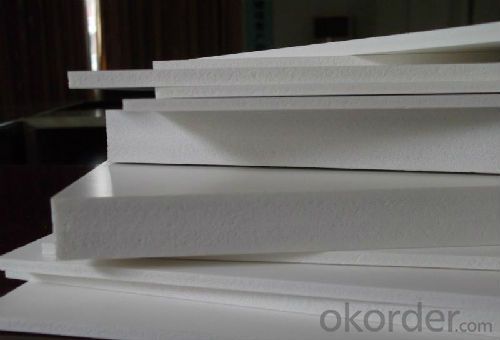

Geotextile R63 PVC Foam Sheet, Plastic PVC Resin, PVC Extruded Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product Description:

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet series. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

2.Application:

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3.Feature:

1) UVprotected, Antichemical corrosion

2) Fire retardant and it can automatically extinguish by itself

3) Sound insulation, sound absorption, heat insulation and heat preservation

4) Moistureresistant, mildew proof, water repellent and shock proof

5) Nondeformation, agingresistant, color fastness for a very long time through particular formula

6) Light weight, easy and convenient for storage, transportation and using

7) It has a smooth and hard surface and is suitable for painting

4.Specifications:

1 | Product | PVC Foam sheet |

2 | Standard size | 1560mm × 3050mm |

3 | Thickness | 2mm-4mm |

4 | Density | 0.5g/cm3 |

5 | Color | White, Black, Red, Green, Pink, Grey, Blue, Yellow, etc |

6 | Executive standard | QB/T 2463.1-1999 |

7 | Certificate | ISO、SGS PONY Cetification |

8 | Weldable | Yes |

10 | Packing | Carton box or wooden pallet packing |

11 | production capability | 500000 pcs per month |

12 | Life Span | >50 years |

13 | Flame retardance | self-extinguishing less than 5 seconds |

5.RFQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

Q: Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product,

we will offer you the best design assistance.

Q: What factors affect the price?

A: Style, material, dimension, quantity, logo etc.AS for your inquiry, try to give us all these information to get exact quotation.

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- Geotextiles used in geosynthetic tubes typically have specific specifications that vary depending on the specific application and project requirements. These specifications may include factors such as tensile strength, puncture resistance, permeability, UV resistance, and fabric weight. The specific specifications for geotextiles used in geosynthetic tubes should be determined based on the intended use and the engineering design of the project.

- Q: Can geotextiles be used for reinforcement of slope toe protection systems?

- Yes, geotextiles can be used for reinforcement of slope toe protection systems. Geotextiles are often utilized in slope stabilization projects to provide reinforcement and prevent erosion at the base of slopes. They can effectively enhance the stability of slope toe protection systems by distributing loads, improving drainage, and reducing the risk of soil erosion.

- Q: Where are geotextiles used?

- Geotextiles are used in various civil engineering and environmental applications, including road construction, erosion control, drainage systems, landfills, and retaining walls.

- Q: How do geotextiles contribute to slope stability analysis?

- Geotextiles play a crucial role in slope stability analysis by providing reinforcement and soil stabilization. They are often used to improve the internal strength and mechanical properties of soils, preventing erosion and maintaining slope integrity. Geotextiles act as a barrier, distributing loads and reducing the potential for soil movement. Their high tensile strength helps in reinforcing slopes and retaining walls, increasing overall stability and reducing the risk of slope failure.

- Q: How do geotextiles help in filtration of stormwater?

- Geotextiles help in the filtration of stormwater by acting as a barrier that allows water to pass through while trapping sediment, debris, and pollutants. They prevent these contaminants from entering the drainage system, improving water quality and reducing the risk of clogging in stormwater infrastructure. Additionally, geotextiles promote infiltration, allowing stormwater to percolate into the underlying soil, thus replenishing groundwater levels and reducing the chances of flooding.

- Q: Can geotextiles be used in coastal erosion control in beach nourishment projects?

- Yes, geotextiles can be used in coastal erosion control in beach nourishment projects. Geotextiles are often employed as a part of a layered system to prevent erosion by stabilizing the beach sediment. They act as a barrier between the beach material and the underlying soil, reducing erosion caused by water movement and wave action. Additionally, geotextiles can help to retain and distribute sand, enhancing beach nourishment efforts and providing long-term protection against coastal erosion.

- Q: Geotextile detection frequency

- GB / T-2009 / ISO9862: 2005 does not specify the frequency, but according to the general provisions of the construction material is required to declare the material inspection, the specific number of consultation with the testing agency, the general geotextile detection: thickness (sample length 1m, (Sample length 1m, the number of samples 10 10 × 10), tensile properties (wide stretch, trapezoidal tear (sample length 2m, the number of samples vertical and horizontal to the five blocks ))

- Q: Can geotextiles be used in coastal revetment projects?

- Yes, geotextiles can be used in coastal revetment projects. Geotextiles are commonly used in coastal engineering to reinforce and stabilize soil and sediment in coastal areas. They can be used as a filter layer to prevent erosion, as a barrier to control water flow, or as a reinforcement layer to enhance the stability of revetment structures. Geotextiles offer several advantages in coastal revetment projects, including improved durability, reduced maintenance, and increased resilience to wave action and tidal forces.

- Q: How do geotextiles help in preventing piping failure?

- Geotextiles help in preventing piping failure by providing soil stabilization and erosion control. They act as a barrier between the soil particles, preventing their movement and reducing the potential for internal erosion. Additionally, geotextiles improve the drainage characteristics of the soil, allowing water to flow through while retaining the soil particles in place. This helps in maintaining the integrity of the soil structure and reducing the risk of piping failure.

- Q: What are the different geotextile puncture resistance test methods?

- There are several different geotextile puncture resistance test methods, including the ASTM D4833 puncture test, ASTM D6241 puncture test, and the ISO 12236 puncture test. These tests involve applying a force to a geotextile specimen using a puncture probe or cone, and measuring the force required to puncture the material. These methods help determine the puncture resistance and durability of geotextiles for various applications.

Send your message to us

Geotextile R63 PVC Foam Sheet, Plastic PVC Resin, PVC Extruded Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 ft

- Supply Capability:

- 500000 ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords