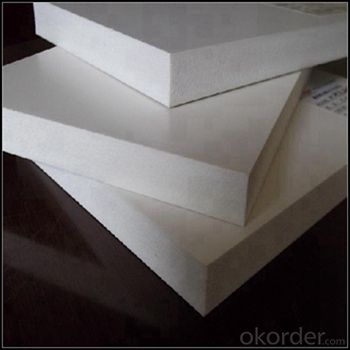

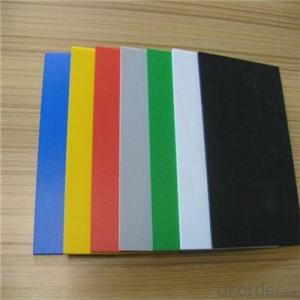

High Density PVC Foam Board Plastic Sheets 1-30mm for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

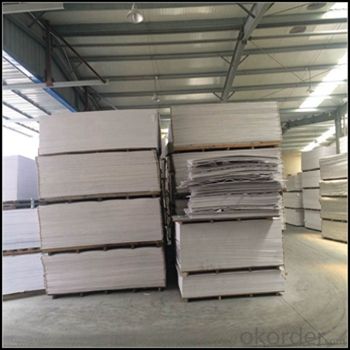

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

a kind of high-tech product, is produced by special machinery and technology processing, has excellent corrosion resistance, insulation, and have a certain mechanical strength. The main material new PVC resin can be foamed and extruded into a special sheet with many advantages and uses wildly. It's a good substitute for wood.

Product Features

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

•Non-sticky

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Details

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Certificate | SGS |

7 | Weldable | Yes |

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

FAQ

Sample: Can I get samples?

Yes, samples are available and can be provided free of charge, customer only need to pay for the shipping cost.

2. Is OEM or Custom Order available?

Yes, we can do custom order according to drawings or photos or samples.

Pictures

- Q: What are the different grades available for plastic sheets?

- There are various grades available for plastic sheets, including general-purpose grades, engineering grades, and high-performance grades. These grades differ in terms of their physical, mechanical, and thermal properties, as well as their specific applications and industry standards. The choice of grade depends on the intended use of the plastic sheet, such as whether it requires high impact resistance, chemical resistance, UV stability, or other specific properties.

- Q: How do plastic sheets handle drilling and cutting?

- Plastic sheets are generally easy to drill and cut due to their malleable and lightweight nature. However, the specific handling of drilling and cutting plastic sheets may vary depending on the type of plastic being used. It is important to choose the appropriate tools and techniques to ensure clean and precise cuts, as excessive force or improper methods may cause cracking or damage to the plastic.

- Q: How do plastic sheets compare to ABS sheets?

- Plastic sheets and ABS sheets have distinct properties and uses. ABS (Acrylonitrile Butadiene Styrene) sheets are a specific type of plastic sheet known for their excellent impact resistance and durability. They are commonly used in automotive parts, electronics, and toys due to their strength and ability to withstand heavy-duty applications. On the other hand, plastic sheets encompass a broader category and can include various materials such as acrylic, polycarbonate, and polyethylene. Each type of plastic sheet has its own unique characteristics and applications. While ABS sheets excel in impact resistance, other plastic sheets might offer superior optical clarity, chemical resistance, or flexibility. Ultimately, the choice between plastic sheets and ABS sheets depends on the specific requirements of the project or application at hand.

- Q: Are plastic sheets resistant to impact?

- Yes, plastic sheets are generally resistant to impact as they are designed to withstand and absorb physical forces without breaking or cracking easily.

- Q: I am building a backyard ice rink which is 20x30 feet, so I need a sheet of plastic which is at least 25x35 ft. The widest poly sheeting I can find is 20x100. Where can I find a shorter but wider one? It should be at least 6 mil and I would prefer clear so it wont kill the grass.

- call your local hardware store. I just put down 6 mill plastic under my river rocks in my back yard. They sell it in rolls of 24 feet wide and 100 feet long . 24 x 100 cost me about $60.

- Q: It looks like a plastic, but I know there is a specific name for it.And maybe if you know the name, what big brand stores sell them?thank you soooo much for any help!

- Photo gels, and none. They're a specialty item

- Q: Wooden block or plastic block?

- Wood chopping board thickness, strong toughness, suitable for cutting meat or hard food, absorbent, difficult to dry, wet long time cause mildew, caused by intestinal disease. When choosing to birch, willow, locust wood or chopping board made of white fruit good.

- Q: What's glued to the plastic buckle?. Which glue does the wallpaper glue onto the plastic gusset plate?

- You can use acrylic pressure-sensitive adhesive (adhesive), brush evenly on the buckle or wallpaper, drying, curing, and then wallpaper and buckle together.

- Q: I have a house in an area (southern Ontario) that is subject to wind-storms. I want to enclose my side porch in plastic so that I can smoke there - I just had a baby and can't smoke inside anymore. I put up 5 mm plastic with staples and strapping wood held up with finishing nails, but in the first wind-storm most of it came down. Would tarps work better? I can't afford to do it in properly with lattice and plywood right now, although that is my ultimate goal. Also I am alone here with my baby, my husband is a long-hauler and I need to be able to do this myself. I can operate a nail gun, a skil-saw, a staplegun. Please advise!

- Try using the metal disks that roofers use to help hold shingles in place. This will spread the force around a larger area, instead of concentrating it right around the staple or nail. I don't know what they're called, but I suspect you can go to Home Depot or a similar home-improvement store and find them.

- Q: I can save about $20 if I learn an effective method.

- the effective way to warp wood is steaming,that you must expose the sheet to hot vapor,from any cooking vessel in an enclosed space,then IMMEDIATELY put load on them on a flat surface,you must prepare every thing before you start .leave it in hot dry place for 48 hr,lift the loads and use sheets,if you are not ready to use them yet,keep them under load until you get ready. try to block the steam from escape or hurt you,by covering the whole lump with a thick heavy tent cloth or similar

Send your message to us

High Density PVC Foam Board Plastic Sheets 1-30mm for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords