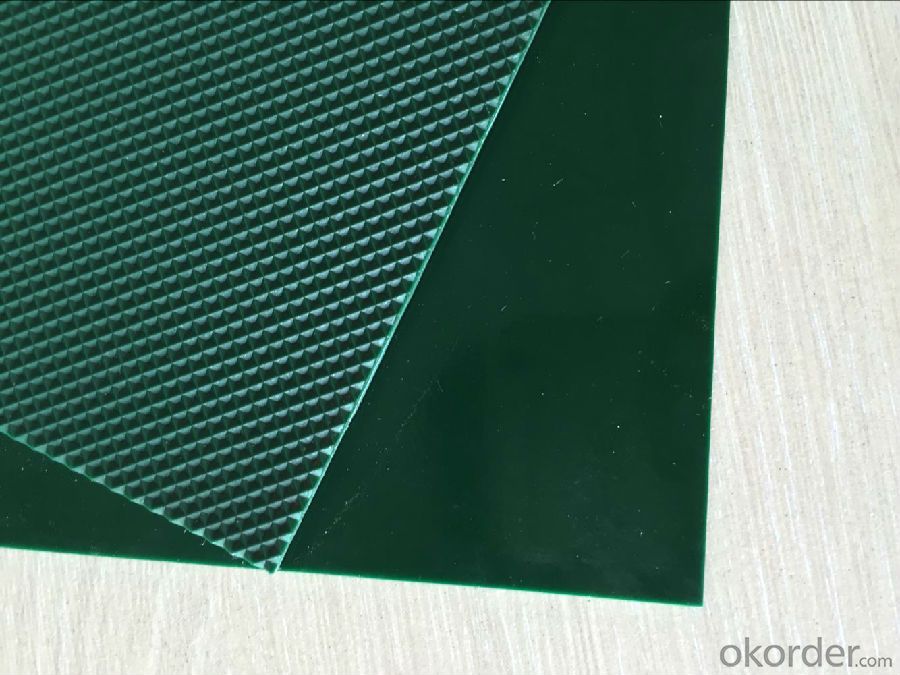

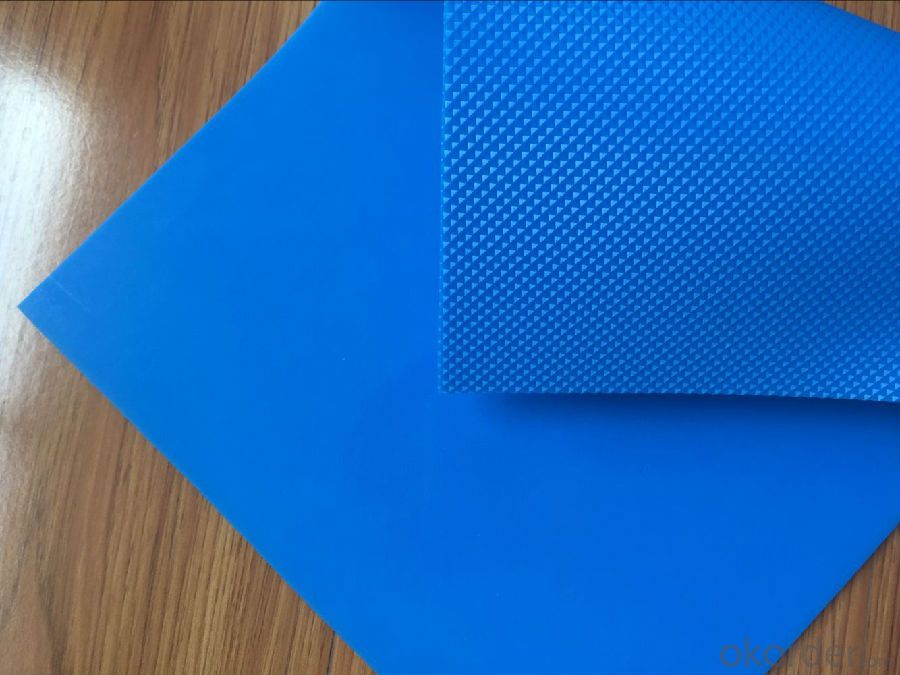

PVC Conveyor Belt White/Blue/Green Smooth Surface Diamond Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt White/Blue/Green Smooth Surface Diamond Pattern

We can divide the conveyor belt into three categories: PVC conveyor belt, PU conveyor belt and some special material, such as silica gel, rubber.

conveyor belt fabric layers: A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

Feature PVC Conveyor Belt:

1.Natural rubber thin belt body with high strength, light weight;

2.Anti-abrasive, impact resistant, corrosion resistant;

3.Softy belt body, good flexibility, excellent trough;

4.Vulcanization molding;

5.Long service life.

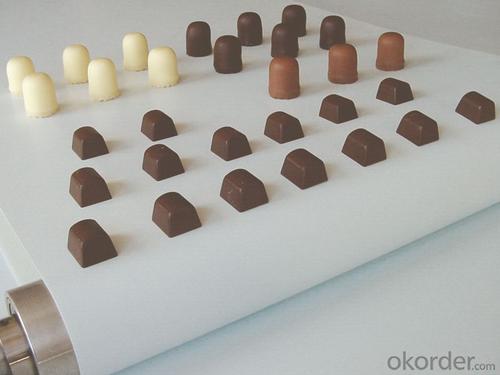

Photos of PVC Conveyor Belt

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the most effective way to reduce the environmental pollution caused by plastic bags?

- White pollution is one of the plastic packages that are difficult to degrade. Disposable foam tableware such as fast and we used plastic bags and so on. It is very serious environmental pollution, buried in the soil is difficult to decompose, the soil will lead to reduced capacity, if the burning causes air pollution, so I do not advocate or less with it, buy the best own tools to reduce its use.

- Q: How are olive nets removed after harvesting?

- Olive nets are typically removed after harvesting by simply lifting them up from the ground, carefully gathering all the olives that have been caught in the net. The collected olives are then separated from any debris or leaves, and further processed for oil production or consumption.

- Q: What materials are olive nets made of?

- Olive nets are typically made of high-density polyethylene (HDPE) or polypropylene (PP) materials.

- Q: How does an olive net affect the overall crop rotation practices?

- An olive net can positively impact overall crop rotation practices by providing protection to the olive trees during the harvest season. It helps prevent damage to the crop caused by falling olives or external factors such as wind, rain, or pests. This increased protection allows for a more reliable and consistent olive harvest, which in turn facilitates the implementation of effective crop rotation practices. With a stable olive crop, farmers can better plan and rotate other crops in their fields, optimizing soil health, minimizing disease and pest risks, and improving overall agricultural productivity.

- Q: Can olive nets be used in conjunction with other harvesting tools?

- Yes, olive nets can be used in conjunction with other harvesting tools such as rakes, shakers, or mechanical harvesters to facilitate the collection of olives. The nets are typically spread beneath the olive tree branches to catch the falling fruits, while other tools are used to shake the branches or physically remove olives from the tree. This combined approach can increase efficiency and productivity during the olive harvesting process.

- Q: How long does an olive net typically last?

- An olive net typically lasts around 5 to 7 years, depending on the quality of the material and the level of maintenance.

- Q: Do olive nets require any special treatment before installation?

- Yes, olive nets typically require some special treatment before installation. They should be cleaned and thoroughly dried to remove any dirt, debris, or moisture that may have accumulated. Additionally, it is important to inspect the nets for any damages or tears and repair them if necessary. This ensures that the nets are in optimal condition for effective olive harvesting and reduces the risk of contamination or damage to the olives during the process.

- Q: How does an olive net affect the ripening process of the olives?

- An olive net plays a significant role in the ripening process of olives by providing protection from external factors. It shields the olives from direct sunlight, reducing heat stress and preventing sunburn, which can negatively impact their ripening process. Additionally, the net creates a microclimate that helps maintain consistent humidity levels, which is crucial for optimal ripening. By creating a barrier against birds and other animals, the net also safeguards the olives from potential damage or loss. Overall, an olive net ensures a controlled environment that promotes healthy and uniform ripening of the olives.

- Q: Can olive nets be used in areas with high salinity in the soil?

- Olive nets can be used in areas with high salinity in the soil, but precautions should be taken to minimize potential damage. Salt in the soil can have adverse effects on olive trees, affecting their growth and productivity. Therefore, it is advisable to implement proper irrigation and drainage systems, as well as regular soil amendments, to mitigate the impact of salinity. Additionally, selecting olive cultivars that are more tolerant to salt can also help in successfully growing olives in such areas.

- Q: What are the main defects of common plastic products?

- Warpage, deformation: due to forming residual stress, shear stress, cooling stress force and uneven shrinkage caused by insufficient cooling, demoulding; bad, plastic products, insufficient strength, mold deformation and other reasons, the plastic products shape distortion and warpage from Kong Pian, such as the phenomenon of uneven wall thickness.Crack: due to plastic stress is too large, poor cooling, demoulding unevenness, poor performance of plastic or plastic products of poor design and other ills (such as deformation) and other reasons, make plastic products surface and feeding additional fine cracks, or cracking or in the load and the effect of solvent cracking phenomenon.Black spot, a plastic material or due to decomposition of combustible volatiles and air combustion decomposition under high temperature and high pressure combustion with the melt into the cavity, showing black spots, black stripes on the surface of plastic products, plastic products, or along the surface is like carbon burn phenomenon.

Send your message to us

PVC Conveyor Belt White/Blue/Green Smooth Surface Diamond Pattern

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords