PVC Coated Gabions net for River Bank Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production description of PVC Coated Gabions net :

PVC coated gabion or also called plastic gabion which enjoys many excellent advantages, such as corrosion resistance, simple installation, easy transportation and installation, weather proof under natural destroy, no collapse even under big scope of deforming, good permeation can prevent the damage by hydrostatic. Besides these, plastic gabion is also good for plant growing and it mixed to form a integrity with the natural environment.

Features of PVC Coated Gabions net:

* Economic. Just fill the stone into the gabions and seal it.

* Simple installation. No special technology needed.

* Weather proof under natural destroy, corrosion resistant.

* No collapse even under big scope of deforming.

* Sludge in the stones is good for plant growing. Mixed to form a integrity with the natural environment.

* Good permeation can prevent the damage by hydrostatic.

* Less transport freight. It can be folded together for transport and further installation.

Applications:* Control and guide of water or flood * Flood bank or guiding bank * Preventing of rock breaking* Water and soil protection* Bridge protection * Strengthening structure of soil*

Protection engineering of seaside area.

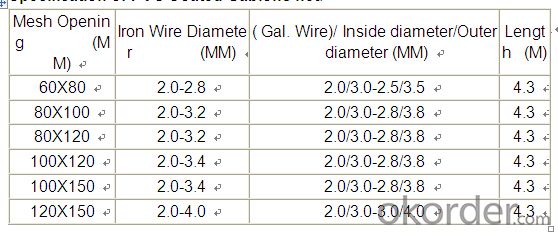

Specification of PVC Coated Gabions net:

|

PVC Coated Gabion

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

- Q: What is the car waterproof sticker material?

- C. metal technology and other: metal technology refers to the aluminum plate and other metal plate through the machine to suppress the concavity and convex surface, and then made of metal paint color, and finally after grinding, drawing and other production of the car stickers (car standard); Area can not be too large, can only be used for a small range of iconic car stickers.

- Q: What is PE waterproof cloth and PVC tarpaulin

- The characteristics and performance index of waterproof cloth products 1. Tensile strength index: warp strength ≥ 2100N / 5CM, zonal strength ≥ 1600N / 5CM; 2. No leakage of water, water pressure ≥ 2000MM water column; 3. Low temperature, cold temperature -20 ℃; 4 Can be mildew, mildew experiment for the first level. Product Usage 1. Can be used car, train, ship cargo tarpaulin; 2. It can be used for the open storage of the harbor airport at the station terminal harbor; 3. Can be set up temporary granary and a variety of crops covered with open-air; 4. Can be used for construction site power construction site and other sites to build temporary shed, temporary warehouse materials; 5. Can be processed camping with tents and various machinery and equipment outside the jacket.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Finished products to buy relatively easy to do some of the cabinet to do more solid material more assured because the plate is also a long-term environmental protection or woodworking directly do better feel that the company can quote their own under the woodworker comparison

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Nanning building waterproof material market where

- Nanning this building waterproof coating does not seem to have a special market, waterproof materials like fast ring building materials market, Wan Tai Long have to sell, as well as Mingxiu Road and Mingxiu Road on both sides of the road have a heavy focus on waterproof materials and companies

- Q: Roof leakage, what materials do the best waterproof

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. The first is to see if there is no cracks in the roof, the original waterproof layer is not aging, the roof of the original SBS waterproofing membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking. There is a block on the roof of the gutter is not blocked in the countryside, there are still a large number of tile-roofed house, when the tiles due to damage caused by the roof leakage, as long as the replacement of tiles can be, this step is also known as "

- Q: I would like to ask how to do in the warm water above,

- 1, I think the flexible mortar, waterproof paint better, because these materials in the construction process, not to warm the temperature caused too much impact, if the shop waterproofing membrane is too heavy, may affect the warm heat. 2, generally in the floor before the warmth, first do a waterproof, paved to warm to do once.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- Due to uneven settlement of buildings and other factors, resulting in deformation of the building structure cracking, leakage phenomenon, for the repair of this situation, you can use a new foreign plugging construction technology - high pressure grouting waterproof repair technology.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

Send your message to us

PVC Coated Gabions net for River Bank Bridge

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 888 m²

- Supply Capability:

- 280000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches