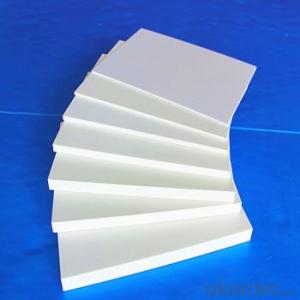

PVC Celuka Foam Board Plastic Sheets - Good Quality & Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

PVC Foam Board Type

pvc celuka foam board, white pvc foam board,black pvc foam board,colored pvc foam board,red pvc foam board,yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.our pvc foam sheet other name is pvc foam board, pvc foam panel, pvc foam plate,rigid pvc foam board,pvc free foam sheet ,pvc plastic foam sheet,pvc forex sheet,pvc crust foam sheet,pvc extruded foam sheet,hard foam pvc sheet,pvc celuka foam sheet,pvc cabinet foam sheet and so on.

PVC Foam Sheet

Estimated area of one hectare is being deforested every second in the world today. A large share of deforestation is being done to meet the global demand for wood. Currently world is facing serious ecological imbalance. Our Eco friendly CREATIVE PVC FOAM BOARD is made out of polymer with thermoplastic nature gives advantage of Re-cycling. Thus we can save lot of natural resources and can be a substitute of wood which ensures least damage to the environment

Pre-sale service:

To provide information and market research,to provide consultation,to provide many kinds of conveniences and market service,etc. Products: PVC Foam Board Machine...

The main purpose of pre-sales service is to help customers make the project planning and system requirements analysis. Make our products maximum to meet clients’ requirements. Also play the greatest overall economic benefits of customers’ investment.

After-sale service:

To install products and test products freely for customers.

To provide the formulas and technologies of relevant products and the information of chemical materials manufactories.

To direct technology aspect of relevant use according to customers’ requirements

To provide technical training for clients’ employees.

To be responsible for maintenance service, door-to-door service under the necessary circumstance.

Technology support:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information of chemical material manufactories.

To provide technical training for clients’ employees.

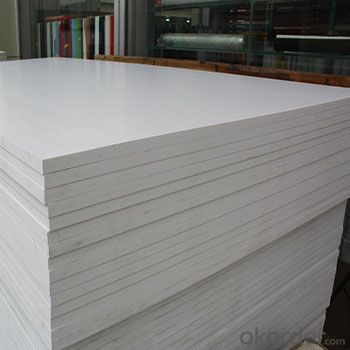

Pictures:

- Q: making a hard plastic cover for my poker table. Home depot wants like 120 bucks for a sheet!! Anyone know of anywhere cheaper?

- www.okorder / ... $30 Go to fabric store to get clear plastic that old ladies put on their dining room tables.

- Q: I'm looking for sheet music for all and any instruments including the vocal on that song.

- Try okorder

- Q: We bought flannel sheets and are left with these lovely plastic packaging with the zipper on top. I would love some creative ideas to reuse them. Links would also be appreciated.

- How about donating them to the homeless so that they can keep their possessions dry. Or using them for packaging for sandwiches. Maybe even use them as freezer bags. Or as a liner for a schoolbag to keep books protected from the rain. You could even use one to protect your laptop, inside or out, as a dustcover. Or a storage bag for all the loose pens that everyone has. If you wanted it a little more exciting, you could always colour a pattern on it using permanent marker...

- Q: Does a sheet of plastic under the bed correct bed bugs?

- Call an exterminator. If you rent rather than own your home then the landlord is responsible for providing a bug free apartment and they have to pay for the exterminator. Does not matter how the infestation started.

- Q: Why build a house with plastic foam?

- The effect of polystyrene foam board:1. protect the main structure of the building and prolong the life of the building. Because the exterior insulation is to place the insulation layer outside the structure, it reduces the pressure caused by the structural deformation caused by the change of temperature, and reduces the erosion of the harmful substances and ultraviolet rays in the air.2. eliminate the "bridge" used in the insulation, the thermal bridge is difficult to avoid, and effectively prevent the thermal insulation production, avoid condensation.3. the wall moist situation improved, the general need to set up internal insulation vapor barrier layer, through the performance of temperature and the external insulation insulation material is much stronger than the main structure, inside the wall is generally not condensation phenomenon, the wall temperature of structure layer was increased to further enhance the wall insulation performance.4., to maintain stability at room temperature, the use of external insulation wall, because the wall heat storage capacity of the larger structure layer in the wall inside, conducive to room temperature to maintain stability.5., increase the use of housing area. Can avoid the two decoration damage to the insulation layer.

- Q: Are plastic sheets impact resistant?

- Yes, plastic sheets can be impact resistant depending on the type of plastic used and its thickness. Some plastics, such as polycarbonate or acrylic, are known for their high impact resistance and are commonly used in applications where protection against impact or breakage is required.

- Q: Are plastic sheets resistant to discoloration from sunlight?

- Yes, plastic sheets are generally resistant to discoloration from sunlight.

- Q: Can plastic sheets be used for protective film applications?

- Yes, plastic sheets can be used for protective film applications. Plastic sheets are often used as a cost-effective solution to protect surfaces from scratches, stains, and other damages. They can be easily applied and removed, providing temporary or long-term protection for a variety of surfaces such as windows, floors, furniture, and electronic screens.

- Q: Wood chopping board, bamboo cutting boards, plastic boards, which is suitable for home?

- First of all the environmental protection should be plastic cutting boardThe plastic chopping board made of polypropylene, polyethylene, not suitable for large oil cut some food, otherwise it is not good for cleaning. The plastic board is not resistant to high temperature, hot stuff on top of cut, easy deformation. Some boards contain lead, cadmium and other plasticizers, long-term use and even the risk of cancer; and some textured plastic boards, but also easy to cut out pieces, enter the body with food, causing damage to the liver and kidney.

- Q: Can plastic sheets be used for skirting boards?

- No, plastic sheets are not commonly used for skirting boards. Skirting boards are typically made from wood, MDF, or PVC materials, as they offer better durability and aesthetic appeal.

Send your message to us

PVC Celuka Foam Board Plastic Sheets - Good Quality & Reasonable Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords