PVC Ceiling Eaves Wall & Ceiling Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

PVC Ceiling for Interior Decoration

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel with high quality and competitive price. And monthly output up to 480,000 Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Specification:

1) Easily installation,surface is smoothness,flatness,without gap when concatenated.

2) High intensity,good quality,not easy to deformation,resist erosion,mothproof,sound insulation,waterproof,fireproof,aging-resisting,durable.

3) It can be processed by drilling,sawing,nailing.Hot bending,hot-folded.

4) Interior decoration for ceiling,wall.Easy cleaning,healthy and environmental.

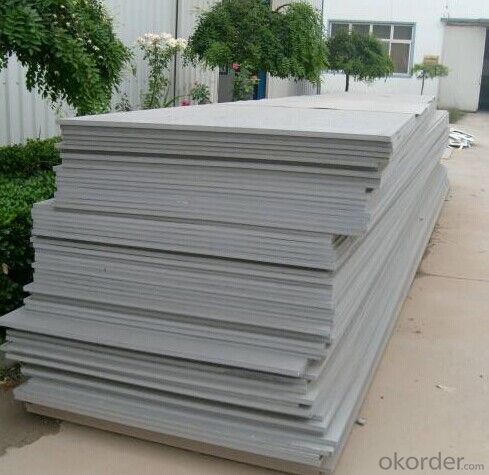

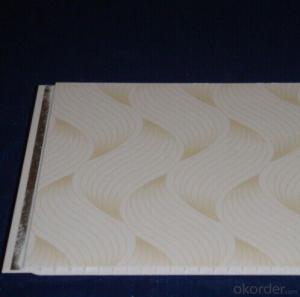

3.Image

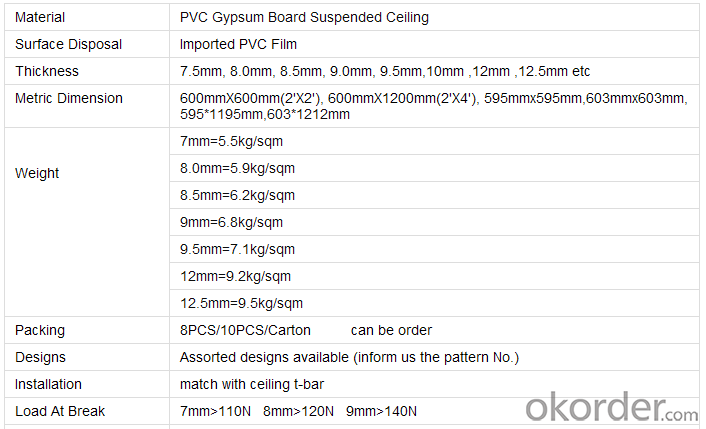

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

- Q: PVC safety sign board 2mm thick, tolerance selection part of the mold activity is not affected by the mold or part of the impact of the activities of the class B it? Accuracy without requirements, 1.8mm thick can meet the standard? Please let the big god to explain. thank!

- Tolerances are generally plus or minus 0.1 mm

- Q: How can PVC board be bonded together

- There is a dedicated PVC adhesive.

- Q: Pvc board density

- PVC sheet Density (g / qm) Thickness range (mm) Low density free foam board (LD-FF) 0,5 - 0,6 3 - 25 Co - extruded core foam sheet 0,6 - 0,65 3 - 20 Crust foam sheet (CELUKA) 0,5 - 0,6 10 (8) - 30 Dense board * 1,4 - 1,5 0,8 - 20 cant see thing* 1,4 0,8 - 10

- Q: Imported PVC flooring and domestic PVC floor What is the difference

- In terms of environmental protection, especially heavy metal (lead, cadmium, etc.) content and volatiles (formaldehyde, etc.) content, imported PVC flooring is more secure than domestic, mainly domestic use of the catalyst and other additives are not strictly used in international Advanced standards, so that in terms of environmental protection, domestic PVC flooring and foreign brand-name PVC floor, there are still different, but this point is more and more people's attention.

- Q: What is the treatment before the color, what kind of paint or paint to color? Satisfied with points

- Spray gun can be directly spray.

- Q: I have a finished basement, and need to add a 2nd waterheater for a new bathroom shower that acts as a carwash, flowing 24gpm! Is there any way I can tie into the existing 3pvc vent pipe for this 2nd waterheater? Adding a 2nd vent would require tearing into the ceiling, which would suck! Theoretically, you could add a couple of 3 PVC motorized ball valves, but it would be much easier to try to keep things simple.

- Hope this helps You may have too also include an upgrade into the size of your fresh air supply

- Q: VC plastic buckle the corners of the corners is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall ...

- Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q: 15 thick PVC board 90X160 how the size of how to fix the wall and PVC above also installed 8 thick pressure and PVC board size

- Can be drilled with a screw fix problem is not exhaustive PVC outside to install 'Agu Li' is it?

- Q: Pvc board to do the props hard, I want to do cos props

- Here with the 8mm board feel quite hard, afraid not hard on a layer of atomic ash

- Q: Will the kitchen toilet ceiling, with aluminum plate is good or good PVC?

- Of course, is the aluminum plate. PVC is cheap, but the quality is far less than aluminum plate.

Send your message to us

PVC Ceiling Eaves Wall & Ceiling Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords