South Africa PVC Ceiling Panel - PVC Ceiling Designs for Bedroom, Film, or Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Introduction:

PVC Ceiling Panels are hollow-core Decorative panels for any part of your home or office interiors.

It is waterproof and very easy to clean, which makes them also ideal for bathrooms, toilets, kitchens, basements, garages and all other living areas.

Especially in damp and moist areas PVC Panel is an excellent alternative to decorate your ceilings effectively, aesthetically pleasing and completely waterproof, bringing home decoration to the next level.

1. At present, we are trying to develop and expand our product in your market.

We hope we can establish business relationship between you and us in the future.

2. We export our goods to the following area:

Middle-east, East Europe, Africa, Russia, South-eastern Asia,and so on.

Regarding the distribution type or exclusivity type, it depends on. We also do

the brand name for the customers’ request only.

3.Payment and Conditions:

Price Term: FOB Shanghai; or FOB Ningbo

Payment Term: 1. T/T : 30% deposit, 70% paid when seeing the copy of B/L by mail or fax.

2. T/T 30% deposit, 70% irrevocable L/C at sight.

4. Our factory having a good management team for the research, development and production of our products.

5. We assure our quality with good technique and effective production control.

Regarding the warranty of our product, there is no international standard. We

have occupation standard and testing report in Mainland.

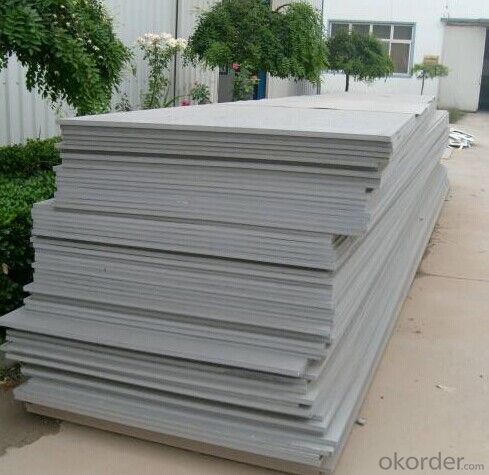

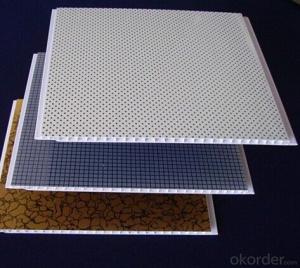

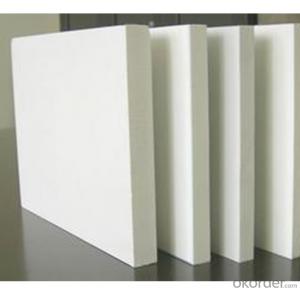

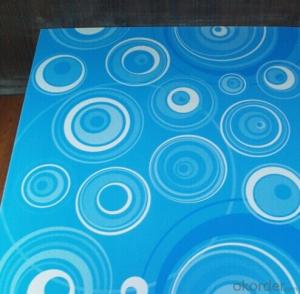

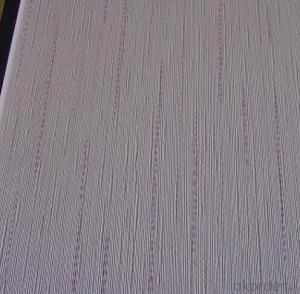

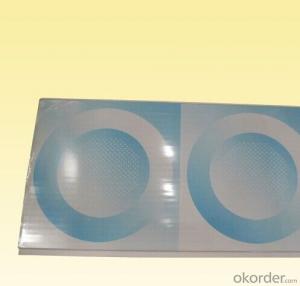

3.Image

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

- Q: Pvc board ceiling each piece of zero sale!

- Should be called plastic buckle plate, cheap more than twenty square, good sixty-seven square square

- Q: Pvc board how to buckle indoor wall skirt

- The bottom of the woodworking board base set to the wall, and then use a professional watering brush, pvc paste to the top, this is a kind of you said that the buckle is similar to the kind of baseboard, grass fixed to the wall, and then grass There is a groove on the back, decorated with the back of the panel directly inserted on the top of the ok

- Q: Ordinary PVC board can be posted wallpaper? Or paint is mainly to improve its appearance

- Can be posted wallpaper, but posted bad words, a long time will be bubbling ~ ~ This is the point of technology and careful Di tick.

- Q: Who knows, acrylic board, organic board, color plate, PVC board What is the difference.

- I suggest you refer to the relevant plastic network or footwear network. These can be consulted. Detailed description, time consuming too much!

- Q: using pvc pipe how would I connect the pipe to the wood posts?

- they make what are called end caps. Drill a hole in the end of the cap and screw it into the wood post then all you have to do is fit the pipes into the caps at each end, There should be enough flexibility in the posts to let you do that.

- Q: What are the specific national standards for pvc? The

- Want to figure out, PP forum, a lot of PVC film information, there are a lot of PVC film and printing bag to do friends, many of which are in the first line operator, responsible for the technology. There are also PVC particles

- Q: What is the difference between acrylic and PVC?

- Acrylic transparency is relatively high, but not impatient, not resistant to solvents and so on ? Acrylic, also known as PMMA, plexiglass and other engineering plastics PVC is PVC, is a general plastic.

- Q: Is ABS a board with PVC?

- VC is the abbreviation of PVC material, is the main raw material of polyvinyl chloride resin, adding the right amount of anti-aging agent, modifier, etc., by mixing, calendering, vacuum plastic and other materials from the process. ABS is just an ordinary board

- Q: Pvc transparent plate and the difference between acrylic

- Differences between PVC transparent and acrylic (PMMA) boards: The main difference is: Transparency and environmental protection, acrylic (PMMA) environmental protection is better than PVC, some manufacturers of PVC may be added in its formula inside the plasticizer (plasticizer), plasticizer choice is not good, then Harmful to the human body; Transparency: Acrylic (PMMA) transparency is better. The other is the price, PVC raw materials cheap, acrylic (PMMA) raw materials expensive.

Send your message to us

South Africa PVC Ceiling Panel - PVC Ceiling Designs for Bedroom, Film, or Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords