Plastic Sheets PVC Ceiling Celuka Foam Sheet for Furniture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Polyvinyl chloride (PVC) is a tough, strong thermoplastic material which has an excellent combination of physical and electrical properties. The products are usually characterized as plasticized or rigid types. Polyvinyl chloride (and co-polymers) is the second most commonly used polyvinyl resins in one of the most versatile plastics.

Product Features

•Excellent clarity, transparency and gloss

•Least thickness variation

•Non-toxic

•Smooth die-cutting

•Superior sealing and welding

•Excellent impact strength

•Higher processing yields

Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Details

1 | Product | PVC Foam board/sheet/panel |

2 | Standard size | 1220mm × 2440mm ; 1560mm × 3050mm ; 2050mm × 3050mm and so on |

3 | Thickness | 1~ 30mm |

4 | Density | 0.4~ 0.8g /cm 3 |

5 | Brand | CMAX |

6 | Certificate | SGS |

7 | Weldable | Yes |

8 | Foam Process | Cellular |

9 | Packing | Carton box or wooden pallet packing |

10 | production capability | 10000 pcs per month |

Characteristics

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding print-ability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

FAQ

PVC foam board sheets foam board sign foam core board for shop discount

1.Q: Can you make design for us?

A: Yes, we offer custom service including sizes, printing, etc from our customers as long as they can provide available artwork to us.

2.Q: What are your company major products?

A: We have more than 10 years experience in producing cosmetic display,jewellery display,watch display,Menu holder,brochure holder,table organizer, gift and promotional items & many others acrylic products.

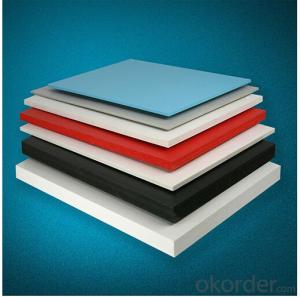

Pictures

- Q: Can plastic sheets be used as a barrier against moisture?

- Yes, plastic sheets can be used as a barrier against moisture. They are commonly used for this purpose as they are impermeable to water and can effectively prevent moisture from passing through.

- Q: Are plastic sheets resistant to high temperatures?

- Yes, plastic sheets can be resistant to high temperatures depending on the type of plastic used. Some plastics like polycarbonate or polypropylene have high heat resistance, while others like PVC may not be as heat resistant.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are commonly used as a cost-effective and easy-to-install option for temporary or low-traffic areas. However, it is important to note that plastic sheets may not be as durable or long-lasting as other flooring materials, and their suitability for specific applications should be assessed based on factors such as foot traffic, moisture resistance, and desired aesthetic.

- Q: i need these answer for my assignment please help me answer these questions

- The object radiates lights of different wavelengths from red to violet (in the visible region of the spectrum) depending on its temperature. When these radiations pass through the red plastic sheet all wavelengths except those emitted by the red plastic sheet are absorbed by that plastic sheet. The colour of the red plastic sheet is due to its own emitted radiations which lie in the red region of the spectrum. So only those radiations are transmitted through the red plastic sheet and enter in to the eye of the observer as a result of which the object appears red.

- Q: Once I went to a workshop, and the moderator used a spray to paste papers in a big plastic sheet. We could remove the papers and paste them again without any problem. Do you know its name and where can I get it? Thank you!

- I've got a can made by 3M. It is called Spray Mount, Artist's Adhesive. I don't know where I bought it years ago, but I shop mostly at Michaels and Hobby Lobby.

- Q: Are plastic sheets transparent to UV light?

- Yes, plastic sheets can be transparent to UV light depending on their composition. Some plastics, such as polycarbonate or acrylic, can allow UV light to pass through while others, like PVC or HDPE, may absorb or block UV rays.

- Q: Are plastic sheets resistant to yellowing over time?

- Yes, plastic sheets are generally resistant to yellowing over time due to their inherent properties and the addition of UV stabilizers during manufacturing.

- Q: Are plastic sheets rigid or flexible?

- Plastic sheets can be both rigid or flexible, depending on their composition and thickness.

- Q: To seal your home up airtight, or close to it?

- I only have enough to wrap around my head.

- Q: How are plastic sheets different from other materials like glass or metal?

- Plastic sheets differ from materials like glass or metal primarily due to their composition and properties. Unlike glass, which is made from silica and metal, which is derived from various elements, plastic sheets are made from synthetic polymers derived from petroleum or natural gas. This difference in composition gives plastic sheets their unique characteristics such as flexibility, lightness, and resistance to impacts and weathering. Plastic sheets are also more cost-effective to produce and easier to shape and mold compared to glass or metal, making them widely used in various industries.

Send your message to us

Plastic Sheets PVC Ceiling Celuka Foam Sheet for Furniture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords