pvc rigid foam board pvc celuka foam board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

- Option:

- "1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm ; or as your request ."

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

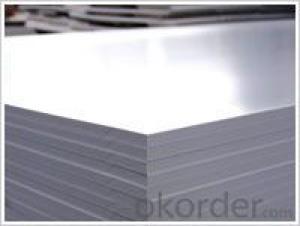

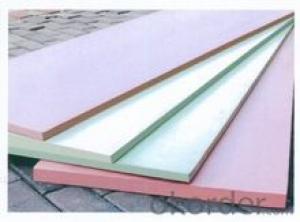

Name | PVC Foam Board/Sheet |

Regular Size | 1220x2440mm, other sizes customized |

Thickness | 0.5mm~50mm |

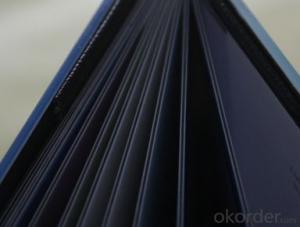

Color | White, Black as usual, Other color as request |

Density | 0.4g/cm3~1.5g/cm3 |

Common Type | PVC Free Foam 0.5mm ~ 50mm |

PVC Celuka Foam 8mm ~50mm | |

Application | a. Advertising, Digital Print, Carve Letters etc. materials |

b. Cabinets, Bathroom Cabinet, Kitchen Cabinet, Furniture etc. raw materials | |

c. Decoration Board, Display Board etc. | |

d. 1mm, 1.5mm thickness PVC Foam Sheets, use as Album, Menu Book, etc inside page material and so on |

Advantages

1.Light weight, easy to storing and transporting

2.Waterproof, fireproof and self-extinguishing, moisture-proof, soundproof and quakeproof

3.Good insulation

4.Good tenacity and high rigidity

5.No water absorption and sopping, no deformation

6.Easily to be processed

7.Good plasticity, being an excellent thermoform material

8.Smooth and clean surface, elegant vision

9.Anti-chemical corrosion, like acid, alkali and salt

10.Beautiful color retain long time, unfading and anti-aging

Detailed Images

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

FAQ

(1) What colors do you have?

Any color and any design is available.

(2) Can you offer the sample?

Yes, the sample is free.and the courier fee is paid by customers.

Pictures

- Q:Can plastic sheets be used for DIY drawer organizers?

- Yes, plastic sheets can be used for DIY drawer organizers. They are versatile and easily customizable, making them a great option for creating compartments and dividers within drawers to help organize and separate items.

- Q:In home improvement, what is the best material used in the kitchen ceiling, aluminum gusset is good, or PVC plate or aluminum plate?

- Each material has its own advantages and disadvantages.. Aluminum buckle: ceiling material Aluminum Alloy plate as raw material, usually aluminum magnesium alloy; can be divided into square plate and strip in two categories according to the shape, the surface treatment process can be divided into spray plate, plate rolling, peritoneal coated plate, the plate has to peritoneal high price and Yi Qingxi, suitable for home use anti tarnishing. Plastic plate: in the plastic on the surface of a thin layer of aluminum, aluminum rolling process showed that the majority of coating, the thickness of the aluminum plate according to the different price difference, in general, more than 12s of aluminum plate is more suitable for home use, too thin will affect the service life. Aluminum plastic board can be used in kitchen and toilet ceiling, but it requires strict waterproof treatment of wooden keel and wooden board of substrate, otherwise it will rot.

- Q:well i was just at this weird consert and there was a plastics thingy so im just wondering

- The percussion sound will deafen you...you'll notice that it is easier on the ears when the sound is behind barriers.

- Q:Are plastic sheets resistant to deformation under load?

- Yes, plastic sheets are generally resistant to deformation under load. However, the level of resistance may vary depending on the type and thickness of the plastic sheet.

- Q:Are plastic sheets resistant to cracking from flexing?

- Yes, plastic sheets are generally resistant to cracking from flexing due to their inherent flexibility and ability to withstand repeated bending without breaking.

- Q:What is the difference between plastic steel plate and PVC pinch plate?

- Plastic steel and plastic doors and windows are almost, PVC is the lowest level of plastic anti-aging, aluminum gusset plate is relatively thin, anti-aging and so on, is the best. Price and quality level is said to be proportional to, PVC two, thirty-one square, plastic steel about forty square meters, and aluminum buckle at about one hundred yuan a square.

- Q:What are the different colors available for plastic sheets?

- There are a wide range of colors available for plastic sheets, including but not limited to, transparent, white, black, blue, green, red, yellow, and various shades in between.

- Q:Can plastic sheets be used for machine guards?

- Yes, plastic sheets can be used for machine guards. Plastic sheets are often used as a cost-effective and versatile option for machine guards. They offer good impact resistance, visibility, and can be customized to fit specific machine requirements. Additionally, plastic sheets are lightweight and easy to install, making them a popular choice for many industrial applications.

- Q:Can plastic sheets be used for electrical insulators in high voltage transformers?

- Yes, plastic sheets can be used as electrical insulators in high voltage transformers.

- Q:Can plastic sheets be used for protective film applications?

- Yes, plastic sheets can be used for protective film applications. They are commonly used to protect surfaces from scratches, dirt, and damage during transportation, storage, or construction processes. Plastic sheets provide a cost-effective and versatile solution for safeguarding various items and surfaces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pvc rigid foam board pvc celuka foam board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

- Option:

- "1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm ; or as your request ."

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords