PVC Ceiling and Wall Panel Best Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling) Description

1.Main Material:PVC resin and calcium carbonate

2. Waterproof and fireproof

3. Easy maintenance

4. Kinds of sizes, attr

2,Main Features of the (PVC Ceiling)

1.Main Material:PVC resin and calcium carbonate

2.PVC Content:40%

3.Pass ISO9001:2008

4.Usage:ceiling panel and wall panel

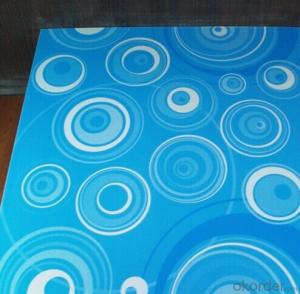

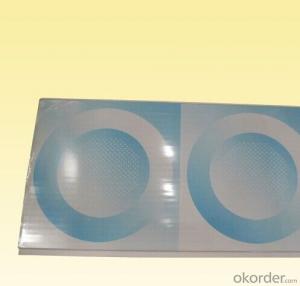

3,(PVC Ceiling) Images

4,(PVC Ceiling) Specification

(1)Technical Information

Item | PVC Panels Ceiling | |||

Usage | Plastic decoration materials for wall and ceilings. | |||

Main Material | PVC resin and calcium carbonate | |||

PVC Ratio | 40%—60% | |||

Type | flat, mid-groove or groove in 1/4 | |||

Surface | Printed ,high gloss, transfer, laminated | |||

Surface effect | bright, high glossy, different colors and diverse patterns | |||

Specification | Width (cm) | Thickness (mm) | Weight (kg) | Length (m) |

20/25/30/60 | 5—9 | 1.6—3.8 | 5.8/5.95 | |

Shape | Rectangle or square | |||

HS Code | 3925900000 | |||

Certification | ISO9001:2008 | |||

Quality | Our panel can bend in a circle easily | |||

Packing | 10PCS/Bales in shrink-film or PE-flim or carton | |||

Function | Fireproof, waterproof, dampproof, soundproof heatproof, high intensity, anti-aging. | |||

5,FAQ of (PVC Ceiling)

(2)Features:

1. Environmental and non-toxic material

2. Waterproof and fireproof

3. Easy maintenance

4. Kinds of sizes, attractive appearance, reasonable price

5. Impact Resistant

6. Light in weight and easy to install can save a lot of time and man power cost

- Q:Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- adequate insulation should be installed. the build is best made of blockwork, double glazed u-pvc windows, with damp proof courses(D.P.C), insulation in roof space or between rafters and D.P.C under roof tiles.

- Q:Pvc board how to install curved curtains

- Bending and straight rail installation is the same way, ah, to the time are straight, but according to the size of the scene is the current curvature of the bend, the installation code is similar.

- Q:I live in a condo, and ive notived theres some kind of pvc piping slightly protruding from above the ceiling in the shower. this pipe occasionaly drips water. not alot, but definitly enough for me to see it and hear it, and take notice. Is this a problem with the above neighbors living above me? what exactly is the purpose of that piping? sorry for the vague description, but i dont know how else to describe it. help is appreciated.

- 1. you should not see exposed pvc pipe in your condo. If you own the condo, I would report this to the association. 2. The leak could be sweat from the pipe, not likely though. 3. It would hard to fix because right now you haven't a clue who the pipe belongs to.

- Q:a restaurant that is partailly elevated. Is heat tape 'really' nessessary? If I wrap it tightly with insulatin then wrap it again with a plastic flex wrap, that ought to be okay, right? I'm not a plumber- just a basic maint. man. Any tips, ideas?

- That is unusual. I believe that insulation would be enough. I've only used heat tape on water lines, not drains. The main issue here is to eliminate any breeze or drafts that may be occurring. Make sure that any cracks or openings that may allow the wind in are sealed up. In my experience it is almost always the direct cold air from wind that causes any freezing. Good luck.

- Q:Pvc board how to paint? With the general way of painting in the pvc board spray paint spray uneven, which know friends told me, his home to buy a few pvc board to do the closet, but how the experimental spray spray do not understand. Polyvinyl chloride material

- Spray the way, if it is pvc, then it is not too suitable, because that way, then pvc translucent no, you can find professional spray paint, the best institutions, because they have paint room, so spray can, Otherwise artificial to do, it is difficult to achieve good results

- Q:PVC crust foam surface can brush latex paint?

- Both want to meet the appetite, but also do not want to involve too much fat? Philips now gives the answer. Philips innovative kitchen appliances Airfryer in Europe, Singapore, South Korea, Malaysia and other countries listed on the great success, and now came to China, Airfryer patented high-speed air circulation technology can make up to 80% of fat can reduce the number of delicious fries, You enjoy delicious French fries and snacks in a healthy and fast way. Oil-free cooking health doubled, delicious not diminished.

- Q:PVC bathroom cabinet is good

- PVC bathroom cabinet very good. PVC bathroom cabinet with PVC materials and other materials, the use of high-density double-leather process PVC sheet, waterproof performance, high hardness. Using brand hinge and paint track. Scratch, high density, durable. Variety of styles, novel design. Pvc bathroom cabinet is a chemical material board made of bathroom cabinet, material is soft, so pvc bathroom cabinet cabinet light, easy to move. Lens maintenance: Bathroom cabinet lenses appear when the stains, with a soft cloth and neutral detergent cleaning. Bathroom countertops, ceramic care: in use, do not be hard to characterize the table, ceramic pots coated with a neutral detergent wipe with a rag. Bathroom cabinet maintenance: to maintain the air circulation between the bathroom to prevent long-term left in the cupboard moisture, try to keep the cabinet dry. PVC bathroom cabinet surface dust. Dirt, you can use a soft cloth dip soap and water. Weak lotion and warm water to wipe the cupboard, do not use a dry cloth to wipe the cabinet, in the process of wiping the cabinet do not use any grinding effect of cleaning A hard cloth, paper towel, or wire ball to avoid scratching the cabinet surface. PVC bathroom cabinet surface oil. Oil. Lubricant pollution, can be wiped with a soft cloth, after a neutral detergent or ammonium solution or with a special detergent to wash. If the acidic liquid attached to the PVC bathroom cabinet, should immediately rinse with water, and then ammonium solution or neutral carbonic acid soda solution dip, and then neutral washing or warm water washing. PVC surface with rainbow pattern, is too much use of detergent or oil caused by washing with warm water neutral wash can be washed away. PVC surface dirt, available 10 percent of nitric acid or grinding detergent washing, PVC bathroom cabinet can also be used special detergent washing, regular care can extend the life of PVC bathroom cabinet.

- Q:I plant processing acrylic board PVC foam board KT board sun board PVC board acrylic board Hibiscus board foam board plastic plate aluminum plastic plate transparent board density board

- Not processing PC board ah, we process PC board, you can exchange

- Q:How does PVC hardness dictate?

- PVC can be divided into soft PVC and hard PVC. Soft PVC is generally used for the floor, ceiling and leather surface, but because the soft PVC contains softeners (which is the difference between soft PVC and hard PVC), easy to become brittle, easy to save, so its use has been limited. Hard PVC does not contain softener, so flexible, easy to shape, not brittle, non-toxic and pollution-free, long storage time, so it has great development and application value.

- Q:How thick is the pvc board?

- Pvc board with soft, hard, foam, etc., in accordance with the production process has extrusion, laminated. Extruded sheet 3mm to 30mm, laminate 3mm to 80mm. I produce laminated sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling and Wall Panel Best Selling Products

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords