Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNC Router For Woodworking

1.1300 x 2500 x 200 mm

2.Air Cooled Spindle

3.CE Certificate & OEM supported

1.SPECIFICATION

WORKING AREA | 1300 X 2500 X 200mm |

SPINDLE POWER | 6KW,AIR COOLED,6000-24000RPM/MIN |

DRIVE SYSTEM | STEPPER MOTOR AND DRIVERS ON X,Y,Z AXIS |

WORKING SPEED | Y AXIS 25M/MIN, X AXIS 25M,Z AXIS 20M/MIN |

CONTROL SYSTEM | NC STUDIO NUMERICAL CNC SYSTEM (ENGLISH LANGUAGE);DSP PROGRAM |

WORKING VOLTAGE | 220V /380V |

TABLE | PVC MATERIAL WITH VACUUM SYSTEM |

OVERALL DIMENSION | 3900 X 2100 X 2100MM |

NET WEIGHT | 1200KGS |

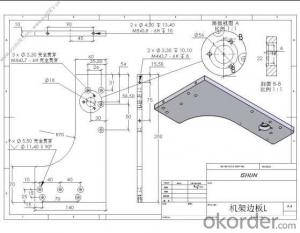

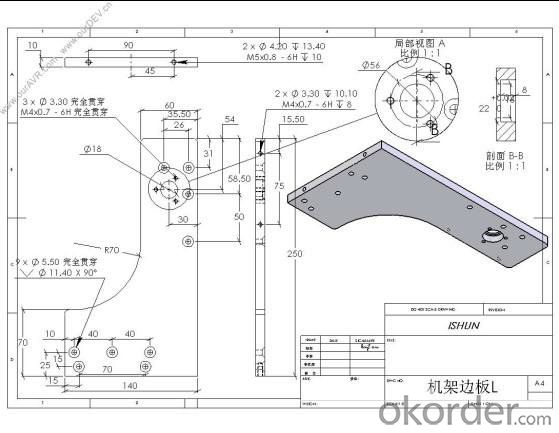

2. DETAIL PARTS INTRODUCTION

a). CONTROL CABINET BOARD

b). PRECISION RAIL GUIDE AND RACKS FOR TRANSMISSION (X&Y AXIS TRANSMISSION)

c). CONTROL CABINET d).OIL PUMPS FOR LUBRICATION

e). LEAD BALL SCRE (Z AXIS TRANSMISSION)

3. OTHER TERMS FOR MACHINERY

SINGLE PACKAGE: WOOD PALLET OR WOODEN CASE (OPTIONAL)

DELIVERY TIME: AFTER CONFIRMATION THE ORDER 35 DAYS

LOADING PORT: QINGDAO PORT, SHANDONG PROVINCE

- Q: Woodworking engraving machine, engraving lines, Y axis, wavy lines, what happened?

- The machine is not running smoothly because of poor maintenance of the machine. Engraving machine not to mess with grease, including oil, butter and so on. Engraving machine maintenance to use dedicated network Di oil, net Di oil lubrication, rust prevention, descaling, three effect one. It is the standard oil for engraving machines

- Q: What are the advantages and scope of CNC woodworking engraving machine?

- Woodworking engraving machine can be used for carving, hollowing, cutting. Of course, this depends on your spindle motor power can not achieve, the general cutting power to a little larger.1. woodworking industry: suitable for three-dimensional wave board processing, cabinet doors, solid wood doors, wooden craft, rabbit paint doors, screens, process window processing, shoe polisher, cabinet panel, auxiliary processing mahjong table, computer desk and panel furniture products.2. advertising industry: advertising signs, logo production, acrylic cutting, plastic mold, a variety of materials advertising decorative products.3. other industries: various large relief carving, shadow carving, widely used in handicraft industry.

- Q: Woodworking engraving machine processing plane appear jagged

- Serrated occurs, adjust the direction of the spindle (clockwise, counter clockwise)

- Q: What's the trouble when using a woodworking engraving machine? How to overhaul

- The motor made a strange noise:Solution: check whether the motor is overloaded; there may exist inside the motor fault, should be timely repair or replacement.

- Q: Large automatic CNC woodworking engraving machine, the general configuration of the current how much money?

- There are different configurations, spindle, drive, precision, and operating system, etc.;In addition, apart from the standard configuration, you need to add other accessories.

- Q: How to draw a woodworking engraving machine?

- The graphics software CAD, CDR, Wen Tai, these software, our woodworking engraving machine are supported

- Q: How to operate the 6090 woodworking engraving machine Weihong control system

- The Thai dispatched insideOpen the Thai2. suites (the layout should be consistent and the carving material)3. in typesetting4. cut 2D 3D and so on5. use a magnifying glass to check the path there is no problem6. output engraving path

- Q: What are the components of a woodworking engraving machine?

- Control medium: with the improvement of numerical control technology, woodworking engraving machine becomes more and more automated, and the control medium is mainly to contact the operator and the machine itself. The common control medium is standard punched tape.

- Q: Woodworking engraving machine which model of higher accuracy, the body as long as the location is where?

- The fuselage is the most important motor and spindle motor problems, can not use the spindle, if the precision is not enough, prone to "different" phenomenon, after all, relatively high speed, the main shaft of the test is relatively large

- Q: Can woodworking engraving machine punch and open?

- Speed mainly depends on the drive motor, spindle power, and the quality of the tool, the three are indispensable.

Send your message to us

Professional cnc engraving machine High quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords