Printing Spray Paint Aerosol Tin Can, 4 Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: spray paint

Printing: CMYK printing as Per Customer Design

2. Detailed Specification

Metal Type:

Tinplate

Use:

Aerosol

Model Number:

diameter 45, 52, 57, 60, 65mm

material:

tinplate

height:

80-300mm

can type:

necked-in

thickness of can body:

0.18mm/ 0.20mm/as required

thickness of cone and done:

0.25/0.28/0.32/ as required

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Advantages of us

1.With ISO9001:2008 certification

2. Over 20 years in producing tin cans

3. Annual capacity: over 400 million pcs

4. Introduced the most advanced iron-printing machine from Japan and Germany, also several full-automatic & high-speed(300pc/minute) can-making lines from Europe.

5. Our products include diameter 45mm, 52mm, 57mm, 60mm, 65mm, 70mm, the can height is from 80-300mm differently

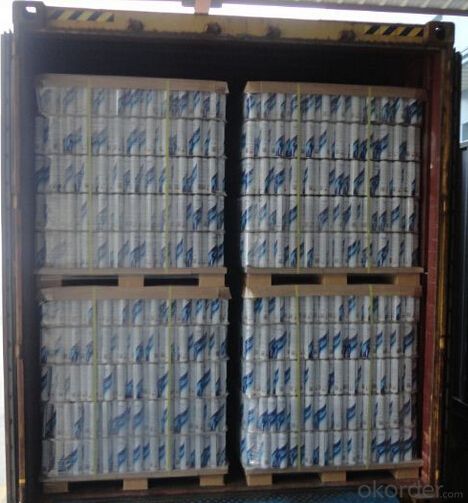

5. Package

5.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q: What is the shelf life of products packaged in tinplate?

- The shelf life of products packaged in tinplate can vary depending on various factors such as the type of product, packaging conditions, and storage conditions. However, tinplate is known for its excellent barrier properties and resistance to corrosion, which can help extend the shelf life of products. In general, products packaged in tinplate can have a relatively long shelf life ranging from several months to a few years.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that prevents corrosion and rusting. The tin layer acts as a barrier, shielding the underlying metal from the corrosive effects of saltwater and other environmental factors, thereby increasing the longevity and durability of the equipment in marine environments.

- Q: How does tinplate contribute to the containment of chemical substances?

- Tinplate contributes to the containment of chemical substances through its excellent barrier properties. The tin coating on the steel substrate forms a protective layer that prevents direct contact between the chemical substances and the metal, reducing the risk of corrosion and contamination. This barrier also helps to maintain the integrity and stability of the chemical substances by preventing interactions with external factors such as moisture, oxygen, and light. Overall, tinplate provides a secure and durable packaging solution for chemical substances, ensuring their safety and quality throughout storage and transportation.

- Q: How is tinplate cut and formed into different shapes?

- Tinplate is cut and formed into different shapes through a process called stamping. In this process, the tinplate sheet is placed between two dies, a male and a female die, and pressure is applied to cut and shape the metal into the desired form. The dies have the desired shape engraved on them, and when pressed together, they cut through the tinplate and form it into the desired shape.

- Q: How does tinplate compare to other packaging materials in terms of cost?

- Tinplate is generally more expensive than other packaging materials such as aluminum or plastic.

- Q: What are the main uses of tinplate?

- The main uses of tinplate include packaging food and beverages, manufacturing cans for aerosol products, creating decorative tin containers, and producing electrical equipment enclosures.

- Q: How does tinplate packaging contribute to reducing food waste?

- Tinplate packaging helps reduce food waste by providing a durable and airtight barrier that protects food from spoilage, contamination, and exposure to air, moisture, and light. It helps extend the shelf life of products, preserving their freshness and nutritional value for longer periods. Additionally, tinplate packaging is highly recyclable, making it a sustainable choice that reduces the environmental impact of food packaging waste.

- Q: Are there any limitations to using tinplate packaging?

- Yes, there are limitations to using tinplate packaging. One limitation is that tinplate can be prone to corrosion, especially in contact with certain types of food or liquids. Another limitation is that tinplate is not as flexible as other packaging materials, making it less suitable for certain product shapes or sizes. Additionally, tinplate packaging can be more expensive compared to alternatives like plastics or cardboard.

- Q: Can tinplate be welded?

- Yes, tinplate can be welded.

- Q: How is tinplate used in the pet food industry?

- Tinplate is commonly used in the pet food industry for packaging cans or containers that store and preserve pet food products. Tinplate is a durable and corrosion-resistant material that helps maintain the quality and freshness of pet food. It also provides a barrier against external elements such as light, moisture, and air, thereby extending the shelf life of the product. Additionally, tinplate cans are easy to open and reseal, making them convenient for pet owners.

Send your message to us

Printing Spray Paint Aerosol Tin Can, 4 Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords