Printed Tinplate, EN 10202, Miscellaneous Can

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

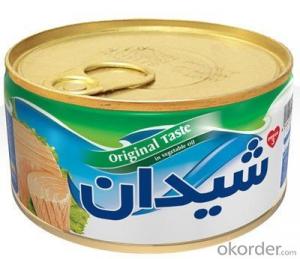

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: What are the common applications of tinplate?

- Tinplate is commonly used in various applications such as food packaging, beverage cans, aerosol containers, decorative items, and electrical components.

- Q: What are the environmental impacts of producing tinplate?

- The production of tinplate has several environmental impacts. The extraction and processing of tin ore can result in habitat destruction, deforestation, and soil erosion. The smelting process emits greenhouse gases, contributing to climate change. Additionally, the use of chemicals during production can contaminate water sources and harm aquatic life. Proper waste management and adopting more sustainable practices can help mitigate these impacts.

- Q: What are the main applications of tinplate in the photography industry?

- Tinplate is commonly used in the photography industry for the production of film canisters and film backing, which are essential components for storing and protecting photographic film. Tinplate's durability, lightness, and ability to provide airtight protection make it an ideal material for these applications. Additionally, tinplate can also be used for the production of photographic chemicals and toners, ensuring their safe and efficient storage.

- Q: What are the potential health risks associated with tinplate packaging?

- Potential health risks associated with tinplate packaging include the possibility of contamination from lead, which can be harmful if ingested, as well as the risk of bisphenol A (BPA) leaching into food or beverages, potentially disrupting hormone function. Additionally, there is a concern that the coating inside tinplate cans may contain harmful chemicals that could migrate into the contents.

- Q: What are the main uses of tinplate?

- Tinplate is primarily used in the packaging industry for food and beverage containers, such as cans for canned foods, beverages, and aerosol products. It provides a protective coating to prevent corrosion and maintains the quality and freshness of the products. Additionally, tinplate finds applications in the manufacturing of various household items, decorative products, and electronic components.

- Q: How does tinplate packaging contribute to product reusability?

- Tinplate packaging contributes to product reusability by providing a durable and long-lasting container that can be reused multiple times. Its sturdy construction ensures that the packaging remains intact even after repeated use, making it ideal for storing and transporting various products. Additionally, tinplate packaging can be easily cleaned and sanitized, allowing it to be used for different purposes without compromising the quality of the contents. This reusability reduces the need for single-use packaging materials, thus minimizing waste and environmental impact.

- Q: What are the main factors influencing the consumer preferences for tinplate packaging?

- The main factors influencing consumer preferences for tinplate packaging include its durability, recyclability, and ability to preserve the quality and freshness of products. Additionally, the aesthetics, brand reputation, and cost-effectiveness of tinplate packaging also play a significant role in shaping consumer preferences.

- Q: How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a highly durable and corrosion-resistant material for the production of energy-efficient appliances, such as refrigerators and air conditioners. Its excellent thermal conductivity properties also aid in the efficient transfer of heat, reducing energy waste. Additionally, tinplate is widely used in the packaging of food and beverages, helping to preserve products and extend their shelf life, thus reducing food waste and energy consumption associated with production and transportation.

- Q: Can tinplate packaging be used for frozen or refrigerated goods?

- Yes, tinplate packaging can be used for frozen or refrigerated goods. Tinplate is a durable and corrosion-resistant material that can withstand low temperatures without compromising the quality and safety of the packaged items. It provides a protective barrier against moisture, light, and oxygen, ensuring the preservation of frozen or refrigerated goods.

- Q: How is tinplate coated on both sides?

- Tinplate is coated on both sides by immersing the steel sheet in a bath of molten tin. This process, known as hot-dipping, ensures that both sides of the steel sheet are evenly coated with a layer of tin, providing protection against corrosion and enhancing its appearance.

Send your message to us

Printed Tinplate, EN 10202, Miscellaneous Can

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords