Printed PVC Foam Board/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1. Brief Introduction

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

2. Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

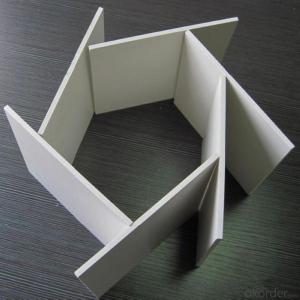

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

3.Product Specification

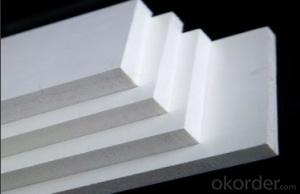

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

4. PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

4. crust plate surface is very smooth, high hardness, not easy scratches, commonly used in the production of cabinets, furniture;

5.Easily to put protective film on one or two sides

6.Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

5.FAQ

1. If the products have some quality problem ,how will you deal with it?

Answer : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

2. Could you provide samples?

Answer : Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

6.Pictures of Products and Factory

- Q: Solid wood furniture and panel furniture which pollution is small?

- Popular, solid wood furniture is certainly a small pollution, but the market is full of a lot of parallel imports of solid wood furniture, such as solid wood paste, obviously the middle of the particleboard, posted a bark on the outside that is solid wood furniture, furniture and sheet furniture in my It seems there is no difference, choose a good solid wood furniture from the material, technology point of view. General people think that solid wood furniture is certainly all solid wood, but simply not, so when you buy furniture to ask the material, all parts of the material to ask, there is a desktop is solid wood, table legs are not, some desktop is good Wood, table legs with parallel wood, but the price tag is good wood price. Anyway, if you are very stressed that pollution is small, you will see manufacturers have no 10 ring certification, which is the most authoritative environmental certification, of course, people have money to buy another matter on the matter. You'd better buy a brand name, so safe, because to tell the truth, many small workshops which produce furniture, and then to the supermarkets to pay a long lease, transformed into a good furniture, and is completely deceptive. There is to shop around!

- Q: Snow Ling plate quality how, I now want to decorate, intended to use snow plate

- My home is last year's decoration, then went to the east side of the building materials plate area, saw a lot of plate brand, the final choice of the snow plate, snow plate in Changsha is the old brand, and bought back after playing the anti-counterfeit label telephone query is Genuine, carpentry master cut, exudes bursts of rosin flavor, straight boast board good, used in children's room do not have to worry about. A: My friend's family has two children, a 5-year-old, another one is only 1 year old, is a typical environmentalists, the product quality requirements are high, but also choose the snow plate, very satisfied.

- Q: PCB aluminum plate plate an oily size is how much

- At present the conventional PCB aluminum substrate size of 400 * 1200mm, 500 * 1200,600 * 1200mm three

- Q: See a lot of people with black frame, comfortable?

- The most common: metal, sheet, pure titanium, solid wood, TR90 Now the glasses frame whether the brand or frame color or the production of materials are varied. A pair of beautiful glasses is not only beautiful appearance, but also need to know when the wearer face and glasses with how to match, so that the more perfect, glasses will play its role in the modification, so you more attractive. Here to understand what glasses look good. Black box glasses. Black-rimmed glasses to wear after the arts Van special thick, and personal temperament will be changed, so that the current market is particularly popular. Black-rimmed glasses to wear, the more prominent personal contours and the overall personal characteristics, therefore, wearing black-rimmed glasses, then in addition to the appropriate face and color, wearing dress and eye makeup are very important, such as Zhao Wei wearing black box glasses , Highlighting the side with a round black frame brought by the charm, simple atmosphere, and its own unique atmosphere is very strong. Today's sheet glasses can be described as all kinds of people are particularly fond of the work complex and delicate, diverse styles, it is important that the color is good, not allergic, it is not easy to fade, it can be wild, itself is in the high-end frame. Whether it is from their own grades or style design is very advantages, and many brands of glasses are made of sheet metal, such as by the industry more appreciated Levi's frame, is used to produce high-grade sheet, beautiful appearance, Wearing fashion is also very good. What glasses are good-looking? Each pair of glasses have their own characteristics, have their own bright spots, a reasonable choice, the correct match, after wearing are generally very good. Moreover, the spectacle frame itself is an ornament, plays the role of landscaping. Domestic brands can consider the trend of the brand "wood ninety", a physical store.

- Q: Is it ok in the decoration? What are the materials used in general?

- If it is their own use, it is recommended or preferred solid wood furniture, followed by plate furniture. Solid wood furniture is the best, environmentally friendly and durable, but the price is slightly higher, plate furniture style, cheap, as long as the choice of attention to its environmental indicators are in line with national standards, and now the use of MDF board, Plant fiber as raw material, the application of urea-formaldehyde resin or other suitable adhesive made of artificial plate. According to the amount of different, divided into high density board, MDF, low density board. MDF due to soft impact resistance, but also easy to re-processing, is the production of a good material furniture. Melamine board, full name is melamine impregnated film paper facing wood-based panel. It is with different colors or textures of paper into the melamine resin adhesive immersion, and then dried to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot Decorative plates. Used for office furniture or kitchen furniture.

- Q: South Asia, Health benefits, Teng Hui FR4, which is relatively expensive?

- Health benefits of expensive, generally large PCB factory are selected benefits of the plate. South Asia is better ink, Tenghui metal substrate plate can also be

- Q: Want to do the whole wardrobe in the bedroom, because of the reasons for the budget so I would like to ask what kind of sheet to do the overall wardrobe more affordable, more argument, I recommend solid wood composite board, and some remember, we talk about , Ask a question, the bathroom cabinet with PVC or solid wood particles can be it?

- Now there are more on the market in the MDF, you can buy their own plate and then find workers on-site cabinet. The The Bathroom cabinet board to use a good moisture-proof plate, you can use melamine board

- Q: How much is a cafe?

- White wax and red oak from the North American material of ash and red oak, such as according to the domestic material, wax for the ash, oak for the oak. These two kinds of wood is a good wood, such as produced for North America, The price is also closer to the two, such as white oak is more expensive. These two kinds of wood have long been used in furniture production, especially in American furniture. American furniture, the most common wood is in turn: white oak, Red rubber, white wax, cherry, maple, black walnut etc ... so the specific choice of which kind of wood, need to see your personal preferences.But if you can not determine whether the wood produced in North America, I suggest you use red rubber. At present, a large number of domestic use of Russian Fraxinus instead of North American white wax, low price. Color yellowish, but can be bleached. Furniture material marked wax. The red oak of the argument generally refers to the North American material, Russia's oak white and yellow, production Out of the furniture generally oak, rather than specific to white rubber or red oak

- Q: What are the main brands of stainless steel plates on the market today?

- General stainless steel is not talking about "brand". Whether it is the oldest "TISCO" or "Baosteel" stainless steel. Stainless steel sheet on the market are mostly 201,304,316 L stainless steel. There are 1Cr13, 2Cr13 and other stainless steel sheet.

Send your message to us

Printed PVC Foam Board/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords