Printed Plastic Biohazard Specimen Bag for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Printed Plastic Biohazard Specimen Bag for Packaging:

Printed Plastic Biohazard Specimen Bag for Packaging are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Printed Plastic Biohazard Specimen Bag for Packaging mainly used for packing in laboratory or medical field etc for biohazard using.

2. Main Features Printed Plastic Biohazard Specimen Bag for Packaging:

Good quality

Experienced manufacturer produced

Good for environment and good printing

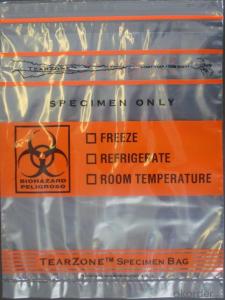

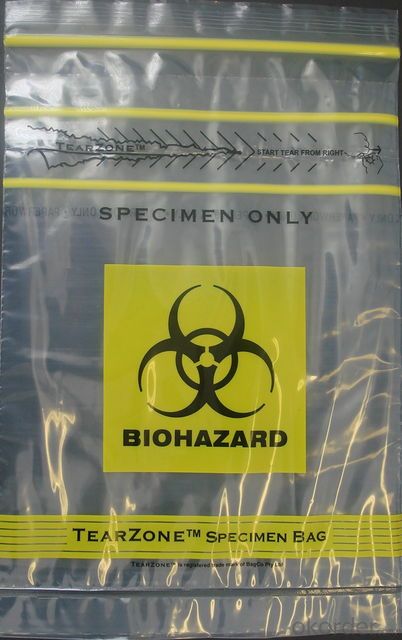

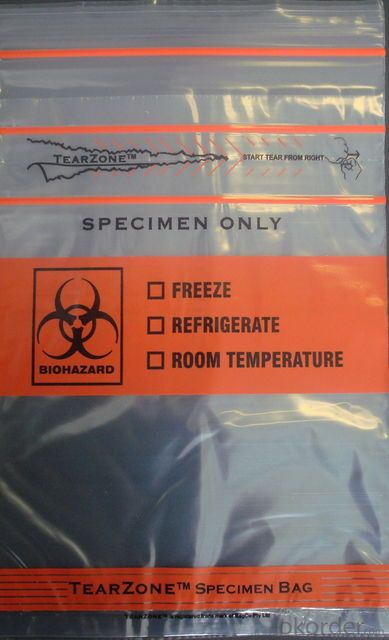

3. Printed Plastic Biohazard Specimen Bag for Packaging Photos:

4. Printed Plastic Biohazard Specimen Bag for Packaging Specification:

1. Material: PE or LDPE or HDPE or Lamiated

2.Size:5*1250px or Customized

3.Thickness:10-200micron

4.Production Flow:

Pre-press: Digital proof & rotogravure-cylinders production (engraving),

Rotogravure printing

Bag making

Quality checkingShipping

5.FAQ of Printed Plastic Biohazard Specimen Bag for Packaging:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Successful packaging must be consistent with the product positioning. Today's consumer groups are very different, for example, the elderly and young people on the acceptance of packaging design is very different, but also take moon cake as an example. The elderly may accept the traditional form of packaging (including graphic design, packaging design, structure design and so on) but the young people can accept the moon cake in the cake box, packed in ice cream box, metal box or even installed in the heavy metal in the punk style. You can't imagine an old lady in the supermarket, with a picture of a skull box filled with 8 pieces of moon cakes.

- Q: What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the goods in the design of material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; enable consumers to use the goods, carrying and preservation is more convenient. In addition, whether the packaging material will cause pollution to the environment, and whether recycling is also very important. Packaging industry is a scientific and systematic project, and the packaging design must take into account the scientific aspects of each link, which also reflects the combination of art and science characteristics.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: Why is the higher the elevation, the more food bags inflate? From a physical point of view

- The higher the altitude, the thinner the air outside, the lower the air pressure; and the air pressure inside the food bag is high, which causes the food bag to drum up. As the height gets higher, the air pressure outside may be lower, and food bags are likely to burst because of the pressure inside and outside

- Q: Is the color of cement packing bags related to cement?

- Portland ash cement, fly ash, silicate sleep and composite Portland cement -- black or blue.The cement packing bags shall clearly indicate the standards of implementation, cement varieties, codes, strength levels, producers' names, production licence marks (QS) and serial numbers, serial numbers, date of packing and net contents.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- Generally Po (polyolefin) material, you can also use PE (polyethylene) material, PP (polypropylene) material, to see your specific needs

- Q: Can aluminum packaging bags be recycled?

- This separation technique is still under study, and no practical solutions are reported.

- Q: How about the material difference of food packaging bag?

- The main contents of food packaging bags are: PVDC (poly partial two vinyl chloride), PE (polyethylene), PA (nylon), EVOH (ethylene / vinyl alcohol copolymer), aluminum film (aluminum +PE), etc.All kinds of materials have different properties and different uses. Generally, food packaging bags are not single materials, and they are usually multilayer compositeThe sausage casing is a single material, PVDC

- Q: What are the types of composite packaging bags?

- Folding general transport packing bagA package of bags weighing 0.5-100 kilograms, mostly woven from plant fibers or synthetic resin fibers, or a multi layer material package made of several flexible materials. For example, straw bags, bags and other cement sacks. - mainly packaging powders, granules, and individual small items.

Send your message to us

Printed Plastic Biohazard Specimen Bag for Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords