Prime Quality Tinplate Products for Food Cans Use with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

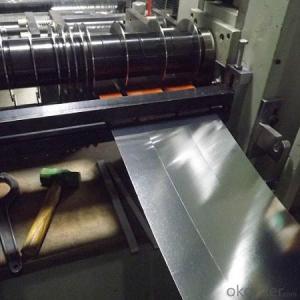

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

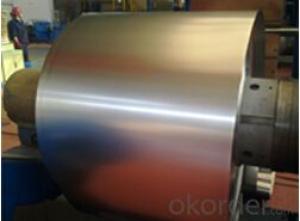

3.Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC,MR

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.18

Width :600MM~1000MM

Temper : T1~T5,DR8

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

E.Do you have other tin coating?

Yes, we can do with E2.8/2.8, E5.6/5.6,D2.8/5.6 etc.

- Q: Can tinplate be used for microwaveable packaging?

- No, tinplate cannot be used for microwaveable packaging as it is not suitable for heating food in a microwave due to the metal composition.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that prevents corrosion and rusting. The tin layer acts as a barrier, shielding the underlying metal from the corrosive effects of saltwater and other environmental factors, thereby increasing the longevity and durability of the equipment in marine environments.

- Q: How does tinplate compare to paperboard in terms of packaging applications?

- Tinplate and paperboard have different characteristics that make them suitable for different packaging applications. Tinplate is known for its durability, resistance to moisture, and ability to provide a barrier against light, air, and odors. It is commonly used for packaging food and beverages, especially canned goods, as well as for aerosol cans and metal containers. Paperboard, on the other hand, is lightweight, flexible, and easily customizable. It is often used for packaging dry goods such as cereal boxes, pharmaceuticals, cosmetics, and certain types of food. Both materials have their strengths and weaknesses, and the choice between them depends on factors such as the specific product being packaged, desired shelf life, branding requirements, and environmental considerations.

- Q: Can tinplate packaging be used for industrial products?

- Yes, tinplate packaging can be used for industrial products. Tinplate is a durable and versatile material that provides excellent protection and preservation for various industrial goods. It is commonly used for packaging chemicals, paints, lubricants, and other industrial products due to its resistance to corrosion, moisture, and impact. Additionally, tinplate packaging can be easily customized to meet specific industrial requirements, making it a suitable choice for such applications.

- Q: How is tinplate affected by different types of sauces and condiments?

- Tinplate is generally resistant to most sauces and condiments due to its protective coating. However, highly acidic or salty sauces may cause corrosion over time, compromising the tinplate's integrity. It is advisable to promptly clean any spills or residues to minimize potential damage.

- Q: What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of musical instrument components, such as guitar picks, harmonica reeds, and various percussion instruments. Its corrosion resistance and durability make it an ideal material for ensuring consistent sound quality and longevity of these instruments. Additionally, tinplate is also utilized for the packaging of musical media, such as CDs and vinyl records, providing a protective and attractive casing for music albums.

- Q: What are the advantages of using tinplate for automotive parts?

- Tinplate offers several advantages for automotive parts. Firstly, it provides excellent corrosion resistance, making it ideal for parts exposed to harsh environmental conditions. Additionally, tinplate offers good formability, allowing for complex shapes and designs, providing flexibility in manufacturing. It also offers high strength and durability, ensuring long-lasting performance and safety. Furthermore, tinplate is lightweight, contributing to improved fuel efficiency and reduced emissions. Lastly, it is a cost-effective material, providing value for money in automotive part production.

- Q: How does tinplate contribute to the preservation of historical artifacts?

- Tinplate contributes to the preservation of historical artifacts by providing a protective coating that prevents corrosion and deterioration. This coating acts as a barrier against moisture, oxygen, and other elements that can cause damage to the artifacts over time. Additionally, tinplate can be used for packaging and storage of these artifacts, providing a safe and secure environment that further helps in preserving their integrity for future generations.

- Q: What are the main factors influencing the consumer preferences for tinplate packaging?

- The main factors influencing consumer preferences for tinplate packaging include its recyclability and sustainability, durability and protective properties, aesthetic appeal and branding opportunities, as well as its ability to preserve product quality and freshness.

- Q: How does tinplate perform in terms of magnetic properties?

- Tinplate has poor magnetic properties, as it is not a magnetic material.

Send your message to us

Prime Quality Tinplate Products for Food Cans Use with Bright Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords