Prime cold rolled steel coils shipping from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56437 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics.

The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of scale permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects Surface

against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion ("rusting") during shipment and warehousing..

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions

and intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal

for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their

chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

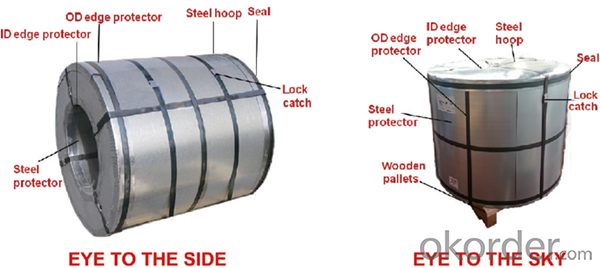

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as

soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Is Ace Steel's wrestling school still running?And do you know if their are any other wrestling schools in chicago?

- Steel okorder

- Q: How are steel coils packaged for transportation?

- Steel coils are commonly prepared for transportation through various methods in order to guarantee their secure and safe delivery. The packaging procedure consists of multiple steps that serve to shield the coils from harm during transit and facilitate their handling and loading onto trucks, ships, or trains. To begin with, steel coils are tightly wound and fastened using steel straps or bands to maintain their compactness and prevent unwinding. These straps are typically made from high-strength steel and securely fastened at regular intervals around the coil's circumference. This not only preserves the coil's shape but also prevents any movement while in transit. Following this, the coils are frequently positioned on wooden or steel pallets to establish a stable foundation and enable easy handling with forklifts or cranes. The pallets are usually tailored to fit the dimensions of the coils and designed to withstand the weight and stress of the loaded coils. In order to provide additional protection, steel coils are often enveloped in a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also serves to prevent any scratching or damage to the coils' outer surface. Moreover, to ensure the coils remain secure and avoid shifting during transit, they are oftentimes housed within a steel or wooden crate. These crates offer an extra layer of protection and stability, particularly when transporting larger coils or multiple coils together. Lastly, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During the loading process, great care is taken to ensure the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents while in transit. In conclusion, steel coils are packaged for transportation by securely binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging procedure serves to safeguard the coils and guarantee their secure and efficient transportation to their intended destination.

- Q: How do steel coils contribute to the HVAC ductwork industry?

- Steel coils are an essential component in the HVAC ductwork industry as they are used to fabricate and shape the ducts. The coils are formed into various sizes and shapes, allowing for efficient air circulation and distribution within heating, ventilation, and air conditioning systems. These durable coils provide structural integrity to the ductwork, ensuring a reliable and long-lasting solution for HVAC installations.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: How are steel coils priced and traded in the market?

- Steel coils are typically priced and traded in the market based on various factors such as the current demand and supply, raw material costs, production costs, and market competition. Steel coil pricing often takes into account the specifications of the coil, including its size, thickness, width, and grade. Additionally, market dynamics, such as global economic conditions, trade policies, and currency fluctuations, can also influence steel coil pricing. Traders and buyers negotiate prices based on these factors, and the final price is determined through a combination of supply and demand dynamics and market forces.

- Q: How are steel coils labeled for identification?

- Steel coils are typically labeled for identification using stickers or tags that contain information such as the coil number, dimensions, weight, grade, and other relevant details.

- Q: How are steel coils used in the construction industry?

- Steel coils are commonly used in the construction industry for various purposes such as fabricating structural components, manufacturing steel pipes, and producing metal roofing and siding materials. The coils are unrolled and processed into different shapes and sizes to meet the specific requirements of construction projects.

- Q: What are the different coil edge options?

- There are several different coil edge options available, including open coil, continuous coil, offset coil, and pocket coil. Each type of coil edge offers unique features and benefits. Open coil edges are interconnected and provide a durable and supportive foundation. Continuous coil edges are made from a single piece of wire and offer enhanced stability and motion isolation. Offset coil edges have an hourglass shape for improved contouring and pressure relief. Pocket coil edges consist of individual fabric-encased coils that move independently, offering personalized support and minimizing motion transfer. Ultimately, the choice of coil edge depends on personal preferences and desired sleeping experience.

- Q: How are steel coils unloaded from a truck or ship?

- Various equipment and techniques are typically employed to unload steel coils from trucks or ships. The unloading procedure depends on the coils' type and size, as well as the available resources and infrastructure at the unloading site. When unloading from a truck, coil hooks are often used in conjunction with a forklift or crane. Careful lifting and positioning of the coils onto the ground or a designated storage area are carried out. Alternatively, specialized roll-off trailers may be fitted to certain trucks, enabling the coils to be rolled off the truck bed. Larger cranes are commonly utilized when unloading from a ship, given the coils' considerable size and weight. These cranes can be situated on either the ship or the dock itself. Specialized lifting hooks or spreader bars are employed to lift the coils from the ship's cargo hold, ensuring they are lowered with care onto the dock or a waiting truck. In certain instances, coil transfer cars or coil trailers are used to transport the coils from the ship's cargo hold to the unloading area. These devices are designed to safely and efficiently move and position the coils. It is important to emphasize that safety measures play a critical role during the unloading process. Properly securing the coils, ensuring equipment stability, and adhering to weight limits are essential to prevent accidents or damage to the coils, truck, or ship. In summary, unloading steel coils from trucks or ships necessitates the use of specialized equipment such as cranes, forklifts, and coil hooks. These tools, combined with meticulous planning and safety precautions, guarantee the efficient and secure transfer of the coils to their designated storage or transportation areas.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Rust is the process of steel oxidizing when in contact with oxygen, this reaction can be much fast if certain components are present, such as wet air or water. However, if the paint completely isolates the steel from the environment, the encompassed steel will never rust as long as paint shields it. Aluminum corrodes but it does not rust. Rust refers only to iron and steel corrosion. Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum, so it isn't as easy to notice as rusted iron.

Send your message to us

Prime cold rolled steel coils shipping from china

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56437 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords