Prepainted Galvanized steel Coil With Red Blue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil With Red Blue :

With Gi as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several Layers of color ,then after firing and cooling, finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding ,corrosion resistance

Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

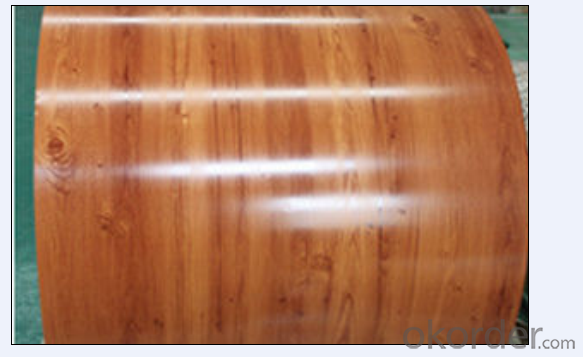

2.Prepainted Galvanized steel Coil Images

3. Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

4.Application for Prepainted Galvanized steel Coil

Outdoor: sandwich panel roofing, roofing structure, surface of sheet of balcony ,frame of window ,door, door of garage, roller shutter door, booth ,cabana, refrigerated wagon and so on .

indoor: frame of door, light steel structure of house, sliding door, folding screen ,ceiling ,internal decoration of elevator

5.FAQ of Prepainted Galvanized steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: What are the different types of steel coil packaging materials used during processing?

- There are several types of steel coil packaging materials commonly used during processing, including but not limited to, steel strapping, plastic strapping, stretch film, shrink film, steel coil covers, and wooden crates.

- Q: I work the Copper plating line at a custom plating facility in MI.I like to use jumper cables with the jumper cable clamps to help confirm electric current is getting to my parts that I am plating. The acids in the Acid copper is constantly eating the steel and copper clamps. WIll I get a good enough current through stainless steel clamps? I use stainless steel hooks, but our maintenance man thinks that is one of the reasons why I have prblems with my parts turning out. I still think it has to do with the clamps getting eatin up. My question is Is stainless steel as good or reliable enough to run an electrical current to my parts if I am using stainless steel or is it best to use another method to try and get a better connection.Please state your sources or experience with working with electricity. I need to get honest answers and not this is my opinion. We are talking about my making a living so this is important to me so I can bring food home to my table. Thanks for all the help.

- Stainless steel is not such a good conductor as copper and the only metal with better conductivity is silver. Additionally, stainless steel will corrode in certain very corrosive environments without the presence of oxygen - i.e. when immersed in salt water. If you're getting problems caused by corrosion of the copper contacts you use there may well be a trade off so my advice is to do a trial and see what works best. You can check the conductivity of metals by simple online search for the period table:

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider are the supplier's reputation and reliability in delivering high-quality products, their ability to meet your specific requirements such as coil size, grade, and coating, their competitive pricing and payment terms, their capacity and ability to handle your required quantity, and their customer service and responsiveness to your needs.

- Q: How are steel coils inspected for thickness and width accuracy?

- Steel coils are inspected for thickness and width accuracy using non-destructive testing methods such as ultrasonic testing and laser measurement systems. Ultrasonic testing involves sending high-frequency sound waves through the coil, and by analyzing the reflected waves, the thickness of the steel can be determined. Laser measurement systems use lasers to scan the width of the coil, providing precise measurements. These inspection methods help ensure that steel coils meet the required thickness and width specifications.

- Q: What is the accuracy of steel tape inspection?

- The precision is the minimum scale of this measuring tool. The minimum scale of the steel tape measure is millimeters, and the data below is the reading data,

- Q: What are the dimensions of steel coils used in the agricultural structure industry?

- The dimensions of steel coils utilized in the agricultural structure sector may differ based on the particular application and requirements at hand. Nevertheless, standard dimensions for steel coils in this industry span from 0.5mm to 3mm in thickness and from 600mm to 1500mm in width. The length of the coils can also vary, but typically falls between 1000mm and 3000mm. These dimensions afford flexibility in constructing agricultural structures like barns, sheds, and storage facilities, all while ensuring ample strength and durability. It is worth noting that precise dimensions may vary depending on the manufacturer and the unique demands of the agricultural project.

- Q: What are the different coil handling equipment options available for steel coils?

- There are several different coil handling equipment options available for steel coils, depending on the specific needs and requirements of the industry. 1. Coil Cars: Coil cars are used to transport steel coils from one location to another within a facility. They are typically equipped with hydraulic or mechanical lifting mechanisms to safely load and unload the coils onto other equipment or storage racks. 2. Coil Upenders: Coil upenders are used to rotate steel coils from a horizontal to a vertical position, or vice versa. This equipment is essential for loading and unloading coils onto coil cars or other machinery, as well as for storage purposes. Upenders can be operated manually or hydraulically, depending on the weight and size of the coils. 3. Coil Lifters: Coil lifters are designed to safely handle steel coils during lifting and transportation. They are typically equipped with adjustable arms or hooks that securely grip the coil's inner diameter. Coil lifters can be operated using hydraulic, mechanical, or electromagnetic mechanisms, depending on the weight and size of the coils. 4. Coil Turnstiles: Coil turnstiles are used to efficiently store and retrieve steel coils. They are designed to hold multiple coils in a vertical position, allowing for easy access and retrieval. Turnstiles can be rotated manually or automatically, using hydraulic or mechanical systems. 5. Coil Reels: Coil reels are used to unwind steel coils and feed them into processing machinery, such as stamping presses or roll forming machines. They are equipped with adjustable tension controls to ensure a smooth and consistent feed. Coil reels can be operated manually or automatically, depending on the level of automation required. 6. Coil Cradles: Coil cradles are used to support steel coils during storage or transportation. They are designed to evenly distribute the weight of the coil, preventing deformation or damage. Coil cradles can be stationary or equipped with wheels for easy movement. Overall, the different coil handling equipment options available for steel coils provide a range of solutions for efficient and safe handling, storage, and processing of these heavy and valuable materials. The choice of equipment will depend on factors such as coil size, weight, production volume, and specific industry requirements.

- Q: Steel coil from vertical to horizontal, what sling needs?

- The sling has little effect, but it is easy to damage the surface of rolled steel.

- Q: Steel resist tension. Then why we provide steel in compression zone ?

- There are several reasons to add compression steel. Keep in mind, supported steel (meaning it can't buckle) resists compression as well. Compression steel helps reduce long term deflections. Concrete creeps under sustained loads. Steel lessens the compression, meaning less sustained compressive stress to cause creep deflection. It makes members more ductile. Since the steel takes some of the compressive stress, the compression block depth is reduced, increasing the strain in the tension steel at failure, resulting in more ductile behavior (the moment at first yield remains largely the same with compression steel added, but the increase in capacity after yield is significant). Compression steel insures that the tension steel yields before the concrete crushes, meaning it helps change the failure mode to tension controlled. It makes beams easier to construct. With bars in the top and bottom, you have longitudinal reinforcement in all 4 corners of the shear stirrups to keep them in place when pouring the concrete. Also, for continuous members, its often easier to run your negative moment steel the full length of the beam rather than trying to cut it off in the positive moment regions. Serviceability concerns. You're going to end up putting steel in that region anyway to for temperature and shrinkage.

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appeal, protect against corrosion, and improve durability.

Send your message to us

Prepainted Galvanized steel Coil With Red Blue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords