Prepainted Galvanized Corrugated Steel Sheet - New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized Corrugated Steel Sheet - New Style:

With GI as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized Corrugated Steel Sheet - New Style:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

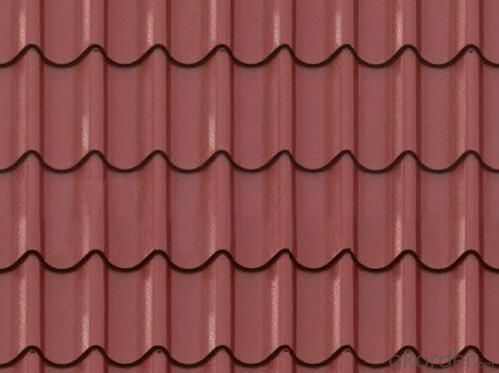

3.Prepainted Galvanized Corrugated Steel Sheet - New Style Images

4.Prepainted Galvanized Corrugated Steel Sheet - New Style Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized Corrugated Steel Sheet - New Style

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your MOQ?

Normally our MOQ is 25mt per size ,but it is up to different size.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel is a versatile material that offers strength, durability, and design flexibility, making it suitable for various architectural purposes such as roofing, cladding, structural framing, and decorative elements. Steel sheets can be shaped, formed, and customized to meet specific architectural requirements, making them a popular choice in modern construction projects.

- Q: Can steel sheets be drilled or machined?

- Yes, steel sheets can be drilled or machined.

- Q: Can steel sheets be used for kitchen backsplashes?

- Yes, steel sheets can be used for kitchen backsplashes. Steel is a versatile and durable material that can withstand the demands of a kitchen environment. Steel sheets are resistant to heat, moisture, and stains, making them an ideal choice for a kitchen backsplash. Additionally, steel backsplashes are easy to clean and maintain, as they can be wiped down with a damp cloth or mild cleaning solution. Steel sheets also offer a sleek and modern aesthetic, adding a touch of sophistication to any kitchen design. However, it is important to note that steel can be prone to scratching, so it is advisable to use a stainless steel variant, which is more resistant to scratches. Overall, steel sheets are a practical and stylish option for kitchen backsplashes.

- Q: What are the different grades of steel sheets available?

- There exists a variety of steel sheet grades, each possessing its own distinctive properties and applications. Among the commonly utilized grades are: 1. Carbon Steel: This grade of steel sheet is the most prevalent and extensively employed. It comprises varying carbon levels and is renowned for its robustness and durability. Carbon steel sheets find utility across diverse sectors, including construction, automotive, and manufacturing. 2. Stainless Steel: Distinguished by its elevated chromium content, this steel sheet grade showcases outstanding resistance to corrosion. Industries such as food processing, chemical, and medical frequently employ stainless steel sheets where corrosion resistance plays a pivotal role. 3. Galvanized Steel: To shield against corrosion, this type of steel sheet is coated with a layer of zinc. Galvanized steel sheets often serve in outdoor settings, such as roofing, fences, and gutters, where exposure to moisture and the elements is commonplace. 4. Alloy Steel: By incorporating additional elements like manganese, nickel, or chromium, this grade of steel sheet enhances its mechanical properties. Alloy steel sheets are extensively used in applications demanding heightened strength, such as construction equipment, aircraft components, and machinery. 5. Tool Steel: Designed with elevated hardness and wear resistance, this grade of steel sheet is ideal for tools and dies. Industries such as automotive, aerospace, and manufacturing frequently employ tool steel sheets. It's crucial to note that these represent only a fraction of the available steel sheet grades, as numerous specialized grades are tailored to specific applications. The choice of grade depends on factors such as desired strength, corrosion resistance, and specific application requirements.

- Q: What are the common thicknesses for galvanized steel sheets?

- The common thicknesses for galvanized steel sheets range from 0.4mm to 3mm, with the most commonly used thicknesses being 0.8mm, 1mm, and 1.2mm.

- Q: How do steel sheets perform in marine environments?

- Steel sheets perform well in marine environments due to their high strength and corrosion resistance. The steel's protective oxide layer helps prevent rusting and deterioration caused by saltwater exposure. Additionally, steel sheets can withstand the harsh conditions of marine environments, including waves, moisture, and extreme temperatures, making them a reliable choice for various marine applications such as shipbuilding and offshore structures.

- Q: Can steel sheets be used in HVAC applications?

- Yes, steel sheets can be used in HVAC applications. Steel sheets are commonly used in HVAC systems for various purposes such as ductwork, ventilation, and fabrication of components like air handling units and heat exchangers. Steel offers excellent strength, durability, and resistance to corrosion, making it suitable for these applications.

- Q: What are the different surface textures available for steel sheets?

- Some of the different surface textures available for steel sheets include smooth, matte, brushed, polished, embossed, and patterned.

- Q: Are steel sheets suitable for roofing?

- Yes, steel sheets are suitable for roofing. Steel is a strong and durable material that can withstand various weather conditions, including high winds, heavy rain, and snow. It also offers excellent protection against fire and is resistant to corrosion. Additionally, steel sheets are lightweight, easy to install, and can be designed in different styles and colors to enhance the aesthetic appeal of a building.

- Q: Can steel sheets be used for flooring or decking?

- Yes, steel sheets can be used for flooring or decking in certain applications. Steel sheets provide durability, strength, and resistance to fire, moisture, and pests, making them suitable for industrial or commercial settings. However, they may require additional insulation or coatings to minimize noise and improve slip resistance.

Send your message to us

Prepainted Galvanized Corrugated Steel Sheet - New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords