Pre-painted Rolled steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

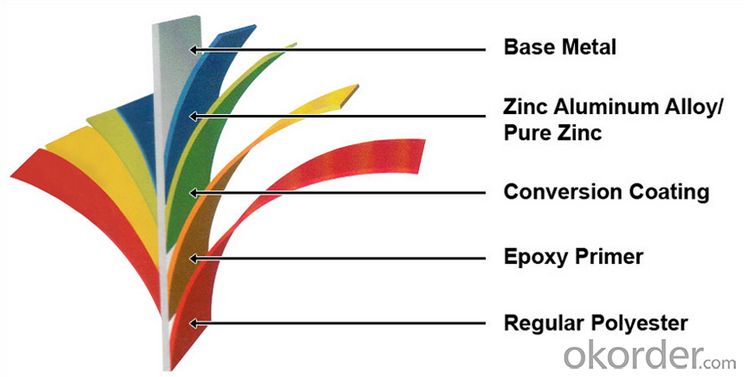

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- How grimy is your range? I actually have a stainless range and all I do is discover a soapy sponge on it, with dish cleansing soap. I get rid of each and all of the knobs and burners approximately as quickly as a week (and every time I fry something and splatter oil everywhere, yet i attempt to disguise issues with foil as quickly as I fry to sidestep a multitude). It takes possibly 5 minutes to scrub my range because I shop it clean and not in any respect, ever use it if it has spills on it. i've got found out via the years to wipe issues up right now, or the spills get baked on and become very confusing to get rid of. My range is electrical powered, so I take off the electrical powered burners and gently wash those with a soapy sponge too (I carry them and rub the soapy sponge on them, then carry them below the faucet to rinse, without getting the plug in factor section moist). My range continues to be very clean this way, and that i take advantage of the rougher side of a non-scratch sponge for something that desires some scrubbing. in the experience that your range has undesirable stains caught on it, you ought to use very, very advantageous metallic wool on it. An SOS pad will paintings, do in basic terms no longer rub too problematic or you will take off the shine from the range. SOS pads are ok on each and all of the immaculate areas of the range. whilst completed washing it, take a humid dish towel and wipe each and all of the cleansing soap off, then dry the range and it will seem large.

- Q: What are the dimensions of a steel coil?

- The dimensions of a steel coil can vary depending on its intended use and manufacturer. However, typical dimensions include a width ranging from 600mm to 2,200mm, a diameter of 600mm to 2,000mm, and a weight ranging from a few hundred kilograms to several metric tons.

- Q: What are the challenges in coil leveling for coated steel?

- To achieve high-quality, flat, and smooth coils, several challenges must be addressed in the process of coil leveling for coated steel. The first challenge lies in the potential damage to the coating during leveling. Coated steel coils are typically covered with materials like zinc or paint, which are susceptible to scratching or marring if mishandled. The leveling process involves passing the coil through a series of rolls, which can cause friction, abrasion, or other mechanical harm to the coating. Therefore, it is crucial to meticulously control the speed, pressure, and alignment of the rolls to minimize coating damage. The second challenge stems from the variations in thickness across the coil. Coated steel coils often exhibit thickness discrepancies due to inherent material properties or production methods. These variations can lead to uneven leveling, resulting in coils with waviness or inconsistent flatness. Achieving uniform leveling across the entire coil surface is vital to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of shape distortion. The coating processes can introduce stresses into the steel, causing the coil to warp or distort during leveling. This distortion can lead to coils with irregular edges or uneven flatness. Proper control of leveling process parameters, such as the number of passes and applied tension, is necessary to minimize shape distortion. Furthermore, the coil leveling process can generate internal stresses in the steel, especially in cold-rolled or heat-treated coated steels. These internal stresses can result in coil spring-back, where the coil attempts to revert to its original shape after leveling. Spring-back can cause coils with undesired curvature or inconsistent flatness. Effective strategies, such as stress relief annealing or employing counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Lastly, handling and storing coated steel coils pose challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions, such as humidity, temperature, and exposure to corrosive substances. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In conclusion, the challenges in coil leveling for coated steel involve minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges necessitates precise control of process parameters, the application of suitable leveling techniques, and strict adherence to quality control measures throughout the entire process.

- Q: What is the weight range of steel coils?

- The weight range of steel coils varies depending on the specific type and dimensions, but they generally range from a few hundred kilograms to several tonnes.

- Q: How are steel coils inspected for flatness variations?

- Steel coils are inspected for flatness variations using specialized equipment such as flatness gauges and laser measurement systems. These tools are used to measure the surface profile of the coil, detecting any deviations from the desired flatness tolerance. Additionally, visual inspection and manual measurements by trained professionals are also carried out to ensure accurate assessment of flatness variations in steel coils.

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they provide the raw material for creating the manifold's structural components. These coils are typically cut, shaped, and welded to form the intricate and durable design required for efficient exhaust gas flow.

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a combination of visual inspections, measurements, and non-destructive testing techniques. These inspections typically involve checking for surface defects, such as cracks, scratches, or corrosion, as well as ensuring the dimensions and weight of the coils meet the required specifications. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, are also used to detect any internal defects that may not be visible to the naked eye. Overall, these comprehensive inspections help ensure that steel coils meet the desired quality standards.

- Q: What is the role of steel coils in the production of fencing materials?

- Steel coils play a crucial role in the production of fencing materials as they are used to create the wire mesh that forms the main structure of the fence. The coils are unraveled and fed into a machine which cuts and shapes the steel into the desired size and form. This wire mesh is then further processed and treated to enhance its strength and durability before being incorporated into the final fencing products.

- Q: How are steel coils processed before being used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. These steps typically include cleaning, pickling, cold rolling, annealing, and coating. Cleaning involves removing any dirt or impurities from the surface of the coil. Pickling is a chemical process that removes scale and oxides from the steel, enhancing its surface quality. Cold rolling reduces the thickness and improves the hardness of the steel. Annealing involves heating the coil and then slowly cooling it to enhance its ductility and reduce internal stresses. Lastly, coating is applied to protect the steel from corrosion or to enhance its appearance.

- Q: How are steel coils used in the manufacturing of tubes?

- Steel coils are used in the manufacturing of tubes by being unwound and fed through a tube mill where they are shaped and welded together to form seamless or welded tubes.

Send your message to us

Pre-painted Rolled steel Coil for Construction Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords