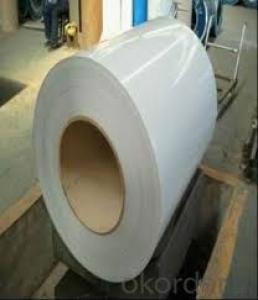

Pre-Painted Galvanised Steel Coil in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-Painted Galvanised Steel Coil in Coil

Description:

Pre-Painted Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

The Pre Painted Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

The base metals for Pre Painted Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Pre Painted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Application:

It’s suitable for indoor or outdoor decoration, color lasting for at least 10 years for outdoor using, could for roll forming., conditioning, micro-wave oven, bread maker,solar water heater,condencing apparatus,Blackboard, white board,chalkboard, hidden cell blackboard,bulletin board,Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf,garbage can, billboard, typewriter, instrument panel, weight sensor, photographic equipment,coffin, fence, Prepainted Galvanized Steel Coil

Electrical appliance:Refrigerator, washer, switch cabinet, instrument cabinet, air

Product Specification:

Color pre painted steel in coil

Thickness: 0.3-0.8mm

Width: 914-1250mm

Inner Diameter: 508mm,610MM

Weight of Steel Coil: 3-8MT

Available Dipped Layer: 50-150g/m2

Coating Type: Al-Zn Alloy

Paint: PE or PVDF

Available Surface Treatment: Passivating & Oiling & AFP & Filming

Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

Front Side Paint Thickness: 15-25μm

Back Side Paint Thickness: 5-10μm

STANDARD:JIS G3312,CGCC

FAQ:

1.Could you tell me the package for the Pre Painted Steel Coil?

Usually Standard export seaworthy package: waterproof paper+steel trip packed+wooden case seaworthy package

2.How about the color of the Pre Painted Steel Coil

The color of the Pre Painted Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue.

3. Can you produce the goods according to our requirements?

Yes, of course, it can be customized according to customer’s requirements.

Protective film can be provided according to customer if you needs.

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: Are steel buildings more durable than concrete building?

- Metal buildings are very cost-effective and costs less than a concrete or a wooden building. Steel prices are quite stable as compared to wood or concrete prices which are constantly rising.

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- This would depend upon the method of fireproofing. Steel used to be insulated with an asbestos coating. Of course the steel under the insulation had the same critical temperature as the uncoated steel but was protected from external heat by the insulation. More commonly it would be an alloy and there are so many that one could not guess except to say it should be higher than the original.

- Q: Why buy recycled steel and from where to buy?

- Recycling old steel is very advantageous to manufacturers because it is always cheaper to use recycled metal scrap in Dubai than to expensively mine iron ore to gain it. Lucky Groups is one the recognized company to deal in recycled steel.

- Q: Can steel coils be coated with magnetically attractive materials?

- Yes, steel coils can be coated with magnetically attractive materials. This process is commonly known as electromagnetic coating or magnetic coating, where a thin layer of magnetically attractive material, such as iron or nickel, is applied onto the surface of the steel coil. This coating enhances the magnetic properties of the steel, making it more responsive to magnetic fields and enabling it to attract or be attracted by magnets.

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- If it has removable choke tubes, just get a MOD or IMP CYL and it will work. If it is a fixed choke, depending upon how old it is, the barrel may be too thing and steel could damage the barrel. If the shotgun is less than 20 years old and with a MOD or more open choke, you should be good to go.

- Q: Does a magnet stick to galvinied steel?

- I will assume your magnet is a relatively strong one. Virtually all galvanized steel sheet is magnetic. Both galvanized iron and steel are magnetic

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures as they are formed and shaped into various components such as panels, frames, and doors. These coils are typically cut, stamped, and bent to the required dimensions, providing the necessary strength and durability for the enclosures. Additionally, steel coils can be coated or painted to enhance their resistance to corrosion and improve the overall aesthetics of the electrical enclosure.

- Q: I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

Send your message to us

Pre-Painted Galvanised Steel Coil in Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords