Ag200 PP Woven Geotextile/Landscape Fabric with 100g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Landscape Fabric Description:

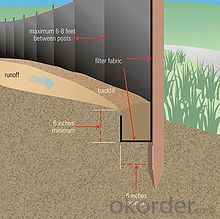

Landscape fabric, also referred to as a filter fence, is a structure composed primarily of geotechnical fabric and that is used as a form of sediment control.These temporary barriers are relatively low in cost, especially when compared to the damages they can prevent.

2. Landscape Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

3. Weed Barrier Fabric Function:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

3.. FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stability to the soil. They act as a separator, preventing the mixing of different soil layers and enhancing the load-bearing capacity of the soil. Geotextiles also help in the drainage of excess water, reducing the chance of soil erosion and promoting consolidation.

- Q: Geosynthetics direct shear instrument reference standards which

- Geosynthetics Direct shear test The abrasive characteristics of the sand / geotextile interface were measured by direct shear test of the standard sand / geotextile contact surface. Test Specimens: 1. Tile the specimen on a rigid horizontal base located in the lower part of the shear box, with the front end of the specimen, and the test leads: ISO.1, GB / T.1, ASTM / D5321, JTGE50T1129, SL / T235-1999. Clamped in front of the shear zone, the sample and the base between the adhesive with adhesive, after bonding the sample should be flat, without folding and folding, the test sample and the base is not allowed between the relative slip; 2. Install the upper shear box: with the pre-quasi-quality standard sand filled with the upper shear box, the thickness of 50mm, sand thickness should be uniform, after the density of the density of 1750kg / m3; 3. Install the horizontal loader , And apply 50KPa to the sample with a reference weight of 50KPa normal pressure.

- Q: Can geotextiles be used in riverbank stabilization projects?

- Yes, geotextiles can be used in riverbank stabilization projects. Geotextiles are often employed to reinforce and protect soil in various civil engineering applications, including riverbank stabilization. They can help prevent erosion, control sediment movement, and provide stability to riverbanks by improving soil strength and drainage.

- Q: How do geotextiles contribute to the stability of road embankments?

- Geotextiles contribute to the stability of road embankments by providing reinforcement and separation between soil layers. They act as a barrier, preventing the mixing of different soil types and enhancing the load-bearing capacity of the embankment. This helps to distribute the applied loads more evenly, reducing settlement and potential failure. Additionally, geotextiles improve drainage and prevent the loss of soil particles, reducing the risk of erosion and maintaining the embankment's integrity over time.

- Q: How do geotextiles help with filtration?

- Geotextiles help with filtration by providing a barrier that allows water to pass through while retaining soil particles and other contaminants, preventing their migration.

- Q: What equipment is geotextile equipment?

- This I do not how clear, and detailed you can go to Long Yun machinery manufacturers to see, his home is specialized in producing this equipment manufacturers, hoping to help you to adopt.

- Q: What are the specifications for geotextiles in green roof applications?

- The specifications for geotextiles in green roof applications typically include requirements for strength, permeability, UV resistance, and root resistance. These geotextiles need to be strong enough to withstand the weight of the green roof system and any potential loads, while also allowing water to drain through and preventing soil erosion. UV resistance is important to ensure the geotextile can withstand prolonged exposure to sunlight without degradation. Additionally, geotextiles used in green roofs should have root resistance properties to prevent plant roots from penetrating and damaging the underlying structure.

- Q: What is the geotextile material?

- Geotextile is made of staple fiber polyester, polypropylene, polyester filament, PP flat silk and other synthetic fibers through acupuncture or weaving made of geotextile, non-woven and industrial non-woven products in one. The general width of 1-6 meters, roll length of 50-100 meters, the quality per unit area of 100-600 grams square meters. According to the different production processes are: polyester / polypropylene staple acupuncture geotextile, PP flat wire woven geotextile, polyester spunbond filament geotextile, single double-sided thermal composite impermeable geotextile, woven geotextile and so on.

- Q: Geotextile 0.2 and 1.0 which is more sunscreen

- 1.0 more sunscreen

- Q: What are the different factors affecting the durability of geotextiles?

- There are several factors that can affect the durability of geotextiles. Some of the key factors include UV exposure, chemical exposure, moisture, temperature variations, mechanical stress, and installation techniques. UV exposure can cause degradation of the geotextile material over time, while chemical exposure can lead to chemical reactions that weaken the fabric. Moisture can also play a role in degrading the material, particularly if it leads to mold or mildew growth. Temperature variations can cause expansion and contraction of the fabric, which can lead to wear and tear. Additionally, mechanical stress from factors such as heavy loads or friction can impact the durability of geotextiles. Finally, improper installation techniques, such as inadequate anchoring or tensioning, can also affect the longevity of geotextiles.

Send your message to us

Ag200 PP Woven Geotextile/Landscape Fabric with 100g

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords