Europe Geogrids Market PP Plastic Polypropylene Geogrid Biaxial for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

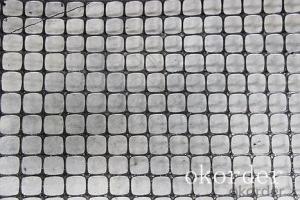

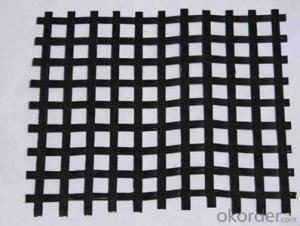

PP Plastic polypropylene geogrid biaxial

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Production function

1:Tensile strength, high creep degeneration small, it has good flexibility, low elongation at break, and effectively solved the engineering distortion and quite a shift, adapt to the environment soil, and can meet the retaining wall of high grade highway tall role.

2:Effectively improve the bearing the reinforcement embedded locks, bite role, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement, enhance the foundation stable performance.

3: Compared with the traditional grille has more strength, high bearing capacity is strong, prevent ageing, friction coefficient.

4: Effectively avoid in construction process by a few words of rolling, damage caused by the construction damage.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

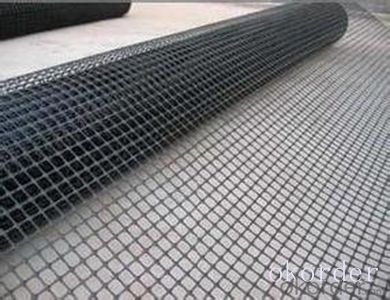

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids suitable for use in temporary retaining walls?

- Yes, geogrids are suitable for use in temporary retaining walls. Geogrids are often used to reinforce and stabilize soil in retaining walls, providing increased strength and stability. They can be easily installed and removed, making them a viable option for temporary structures.

- Q: Can geogrids be used in reinforcement of soil-lime mixtures?

- Yes, geogrids can be used in the reinforcement of soil-lime mixtures. Geogrids are commonly used in civil engineering and construction projects to improve the stability and strength of soil-lime mixtures. They provide additional tensile strength, prevent soil erosion, and enhance the load-bearing capacity of the mixture. By adding geogrids, the performance and durability of soil-lime mixtures can be significantly improved.

- Q: Can geogrids be used in temporary retaining walls?

- Yes, geogrids can be used in temporary retaining walls. Geogrids are commonly used in retaining walls to provide stability and reinforcement to the structure. They can be particularly useful in temporary retaining walls as they offer strong tensile strength and prevent soil erosion, ensuring the wall remains stable during its intended lifespan.

- Q: What is the effect of creep rupture on geogrid performance?

- Creep rupture can significantly impact the performance of geogrids. Geogrids are engineered materials commonly used in civil engineering applications to reinforce soil and provide stability. Creep rupture refers to the gradual deformation and eventual failure of a material under constant load over time. When geogrids experience creep rupture, their structural integrity is compromised, leading to reduced performance and potential failure. The creep rupture phenomenon can cause the geogrids to elongate, lose their load-bearing capacity, and exhibit increased deformation under sustained loads. This can result in the geogrids being unable to effectively reinforce the soil, leading to soil settlement, slope instability, or even structural collapse. To ensure optimal geogrid performance and prevent creep rupture, it is crucial to select geogrids with high creep resistance and proper design considerations. Regular monitoring, maintenance, and periodic inspections are essential to identify signs of creep rupture and address any potential issues promptly.

- Q: How are geogrids installed in the field?

- Geogrids are installed in the field by first preparing the subgrade surface, ensuring it is properly compacted and leveled. Then, the geogrid is unrolled and stretched across the prepared area, with overlaps at the edges for proper connection. The geogrid is then secured to the ground using stakes or pins, ensuring it is taut and properly aligned. Finally, the geogrid is covered with the desired fill material, such as soil or aggregate, which is compacted to provide additional stability and load distribution.

- Q: Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide effective reinforcement by distributing the loads and stabilizing the soil. They help to prevent erosion and improve the stability and durability of coastal structures, making them a reliable solution for coastal protection.

- Q: Glass steel grille is how to produce

- Production process of FRP grid:Preparation of mold - Preparation of mixed resin - glass fiber yarn - (or at the same time) pouring resin and exhaust bubble - mold heating, product curing - mold - finishing - Inspection packaging.

- Q: Characteristics of steel plastic geogrid

- 1 high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type.2, steel plastic composite geogrid vertical wire warp rib braided mesh, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low.

- Q: How do geogrids help with load distribution?

- Geogrids help with load distribution by providing a reinforced structure that distributes the weight of a load evenly across a larger area. They act as a stabilizing layer within the soil, preventing the lateral movement of particles and reducing the potential for settlement or deformation. This helps to enhance the load-bearing capacity of the soil and prevent localized stress concentrations, ensuring a more uniform distribution of loads and improving the overall stability of the structure.

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- Geogrid is a kind of main geosynthetics, compared with other geosynthetics,

Send your message to us

Europe Geogrids Market PP Plastic Polypropylene Geogrid Biaxial for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords