PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP& PE compound membrane waterproof material for walls is made by multiple-ply different materials, especially its aging and weathering resistance layer enables the

membrane possess more longer effective age. It can bond with many kinds of adhesions,

firm and secure. In case of cement-base, cementations agent can be used,

the cementations agent can easily enter into the non-woven felt layer, forms a

well-combination with cement after solidification, permanent durability.

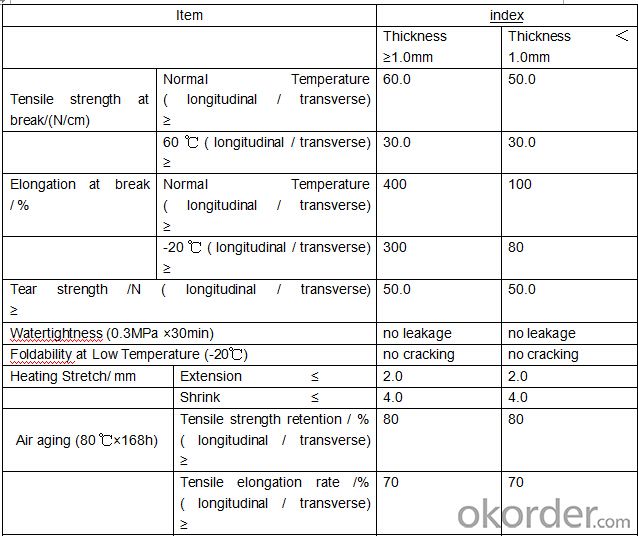

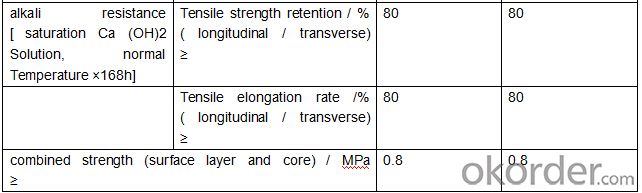

Data Sheet

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to protect structure from water infiltration.

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to ensure that the manufacturer's instructions are followed regarding temperature limitations and proper installation techniques. Cold weather may affect the curing and adhesion process, so additional precautions and proper heating or insulation methods may be necessary during the application.

- Q: Can a waterproofing membrane be used for a commercial building?

- Yes, a waterproofing membrane can be used for a commercial building. Waterproofing membranes are commonly used in commercial buildings to protect the structure and prevent water damage. They provide an effective barrier against moisture and can be applied to various surfaces such as roofs, basements, and foundations. This helps to maintain the integrity and longevity of the building, preventing leaks and potential structural issues.

- Q: How does a waterproofing membrane perform in areas with chemical exposure or solvents?

- A waterproofing membrane is designed to protect surfaces from water penetration and damage. However, its performance in areas with chemical exposure or solvents may vary depending on the type of membrane and the specific chemicals involved. In general, waterproofing membranes are not specifically designed to resist chemical exposure or solvents. While they may provide some level of resistance to certain chemicals, prolonged exposure or contact with aggressive chemicals can compromise their effectiveness. Chemicals can potentially degrade the membrane material, causing it to become brittle, crack, or lose its waterproofing properties over time. To enhance the performance of a waterproofing membrane in areas with chemical exposure or solvents, it is recommended to use a chemical-resistant membrane specifically designed for such environments. These specialized membranes are made of materials that have been tested to withstand the effects of various chemicals and solvents. They offer a higher level of protection and durability, ensuring longevity and preventing damage caused by chemical exposure. It is important to note that the choice of the appropriate waterproofing membrane for areas with chemical exposure or solvents should be made based on the specific chemicals involved and their concentration. Consulting with a professional waterproofing contractor or manufacturer is advisable to ensure the selection of the most suitable membrane for the intended application. Regular inspection and maintenance are also crucial to monitor the performance of a waterproofing membrane in chemical-exposed areas. Any signs of deterioration, such as cracks, leaks, or discoloration, should be addressed promptly to prevent further damage and potential water infiltration. Overall, while a waterproofing membrane can provide some level of protection in areas with chemical exposure or solvents, it is recommended to use a specialized chemical-resistant membrane for long-term performance and durability.

- Q: Can a waterproofing membrane be applied on top of existing roofing systems?

- The application of a waterproofing membrane on existing roofing systems is a common practice in the roofing industry. This method enhances the waterproofing capabilities of the roof by preventing water infiltration. The membrane, which can be made of materials like asphalt, rubber, or synthetic materials, is installed to create a layer that stops water from seeping through. Before applying the waterproofing membrane, it is crucial to evaluate the condition of the existing roof. Any damage or defects should be fixed to provide a solid foundation for the membrane. Additionally, the surface must be thoroughly cleaned and prepared to ensure proper adhesion of the membrane. Once the surface is prepared, the waterproofing membrane can be applied using different methods such as hot-mopping, torching, or adhesive application. Multiple layers of the membrane are typically installed to offer extra protection against water penetration. The application of a waterproofing membrane on top of an existing roofing system offers several advantages. It extends the lifespan of the roof by preventing water damage and leaks. Moreover, it enhances the energy efficiency of the building by reducing heat transfer and air leakage. Additionally, it improves the overall waterproofing capabilities of the roof, safeguarding the underlying structure from moisture-related problems. To determine the most suitable waterproofing membrane and installation method for your specific roofing system, it is essential to consult with a professional roofing contractor. They will evaluate the condition of the existing roof and recommend the best approach to ensure a successful application of the waterproofing membrane.

- Q: Can a waterproofing membrane be used for stadiums and sports arenas?

- Yes, a waterproofing membrane can be used for stadiums and sports arenas. It is a commonly used solution to protect these structures from water damage and leakage. The membrane helps in preventing water penetration and effectively keeps the interior areas dry and safe.

- Q: Can a waterproofing membrane be used for disaster relief structures?

- Yes, a waterproofing membrane can be used for disaster relief structures. Waterproofing membranes are designed to provide protection against water infiltration, which can be crucial in disaster situations where structures need to be protected from flooding or heavy rains. Using a waterproofing membrane can help ensure that relief structures are more resilient and durable, enhancing their effectiveness in providing shelter and protection during and after a disaster.

- Q: Can waterproofing membranes be used on underground structures?

- Yes, waterproofing membranes can be used on underground structures. Waterproofing membranes are designed to provide a barrier against water infiltration and are commonly used in various applications, including underground structures such as basements, tunnels, and underground parking lots. The primary purpose of using waterproofing membranes in underground structures is to prevent water penetration, which can cause damage to the structure and compromise its stability. These membranes are typically made from materials such as modified bitumen, PVC, EPDM, or HDPE, which have excellent water resistance properties. When applied correctly, waterproofing membranes create a continuous and durable barrier that prevents water from seeping through the walls, floors, or foundations of underground structures. They are installed on the exterior of the structure or sometimes as an integral part of the concrete walls or floors during construction. In addition to water resistance, waterproofing membranes also provide protection against other elements such as chemicals, gases, and radon. They can effectively prevent moisture-related issues such as mold growth, deterioration of building materials, and structural damage, ensuring the longevity and integrity of underground structures. It is important to note that proper installation and maintenance of waterproofing membranes are crucial for their effectiveness. A qualified professional should be engaged to assess the specific requirements of the underground structure and recommend the appropriate type of waterproofing membrane and installation method. Overall, waterproofing membranes are a reliable and effective solution for preventing water infiltration in underground structures, providing long-lasting protection and maintaining the structural integrity of the building.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Both interior and exterior surfaces can benefit from the use of a waterproofing membrane. These membranes are created with the purpose of safeguarding surfaces against water infiltration and harm. Rubber, asphalt, or thermoplastic materials are commonly utilized to construct these membranes, which form a barrier to prevent moisture from penetrating. Whether applied to interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane is highly effective in averting issues such as leaks, mold, or structural damage caused by water seepage. It is crucial to carefully consider the unique requirements of each surface and select an appropriate waterproofing membrane for the intended use.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Certainly, a waterproofing membrane can be utilized alongside green building practices. In actuality, integrating a waterproofing membrane into the construction of a green building can greatly enhance its overall sustainability and efficiency. One of the fundamental principles of green building practices is to maximize energy efficiency and decrease the environmental impact of a structure. By installing a waterproofing membrane, the building's outer covering can be shielded from moisture intrusion, thereby preventing water damage and potential mold growth. This, in turn, aids in preserving the structural integrity of the building, reducing the necessity for costly repairs and replacements, which can consume resources and generate waste. Moreover, a waterproofing membrane can contribute to improved indoor air quality. By preventing water infiltration, it assists in creating a dry and healthy living or working environment, minimizing the risk of respiratory problems and other health issues associated with dampness. Furthermore, a waterproofing membrane can enhance the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it lessens the potential for heat loss through moisture evaporation, thus reducing the energy required for heating and cooling. This can lead to decreased energy consumption and lower carbon emissions, aligning with the objectives of green building practices. However, it is crucial to select a waterproofing membrane that is environmentally friendly and compliant with green building standards. Seek out membranes that are crafted from recycled or sustainable materials and possess low VOC (volatile organic compound) content. Additionally, consider opting for a membrane that is designed for longevity and durability, as this can further minimize the environmental impact by reducing the need for replacement over time. In conclusion, a waterproofing membrane can be an invaluable addition to any green building endeavor. It serves to safeguard the building envelope, enhance indoor air quality, and improve energy efficiency. By choosing an environmentally friendly membrane, the overall sustainability of the building can be further enhanced.

- Q: Can a waterproofing membrane be used on tunnels with emergency exits?

- Yes, a waterproofing membrane can be used on tunnels with emergency exits. In fact, it is highly recommended to use a waterproofing membrane in such tunnels to prevent water infiltration and protect the structural integrity of the exits. Waterproofing membranes are designed to create a barrier against water and moisture, ensuring that the tunnels remain dry and free from water damage. This is especially important for emergency exits, as they need to be accessible and functional at all times. By installing a waterproofing membrane, the tunnels can be effectively protected from potential water ingress, ensuring the safety and usability of the emergency exits.

Send your message to us

PP/PE waterproof materials for bathroom and toilet floor waterproofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 30000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords