Mirafi Woven Geotextile Fabric - PP Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Geotextile Product

Geotextiles are permeable fabrics which when used in association with soil, have the ability to separate, filter, reinforce, protect or drain.

Geotextiles are made from either polypropylene or polyester and geotextile fabrics come in three basic forms: woven, needle punched (resembling felt), or heat bonded (resembling ironed felt). In Australia the most popular geotextile used is the polyester needle punched fabric, as the polyester is more UV stable than the polypropylene material.

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

Color:

White, Black, etc

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

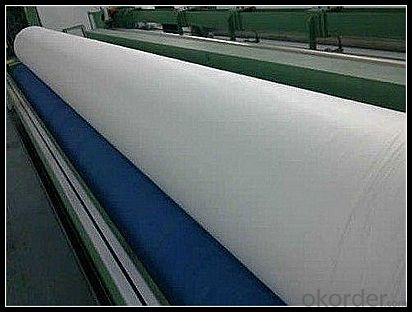

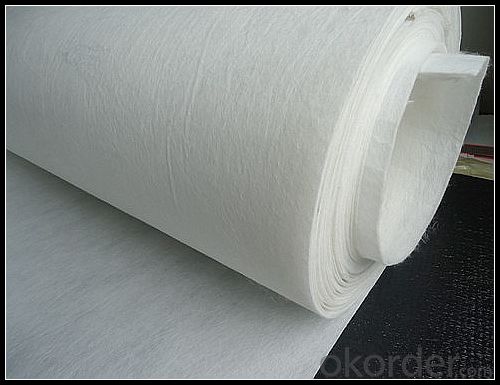

Photos:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What can the geotext crushed material be used?

- Can continue to be used to do geotextile, but because the geotextile after the strength of the fiber is affected, can only be crushed after the geotextile for the production of low grade geotextile, for example, the national standard geotextile crushed material can generally be used Non-standard geotextile production, but in strict accordance with the proportion of added, should not add too much crushed material.

- Q: What are the benefits of using geotextiles in erosion control?

- Geotextiles offer several benefits in erosion control, including their ability to prevent soil erosion, stabilize slopes, and promote vegetation growth. They act as a barrier against water flow, reducing the impact of rainfall and preventing sediment runoff. Geotextiles also enhance soil reinforcement by distributing load and reducing soil movement. Furthermore, they allow for better filtration and drainage, improving water quality and reducing the risk of flooding. Overall, geotextiles provide cost-effective and environmentally friendly solutions for erosion control.

- Q: How do geotextiles help with stabilization of railway tracks?

- Geotextiles play a crucial role in stabilizing railway tracks by providing reinforcement and separation between different layers of the track structure. They prevent the mixing of materials, such as subgrade soil and ballast, while also reducing the lateral movement of the ballast. Geotextiles enhance the overall stability and load-bearing capacity of the track, reducing maintenance needs and extending its lifespan.

- Q: Can plant roots penetrate geotextiles? Which kind of similar material can keep soil and water and let the plant roots pass through it?

- Surely, geotextile is polyester or polypropylene. Do you hear the bag? With this not to solve the ah, green grass for the special, but also to maintain soil and water. I am doing this specifically.

- Q: How do geotextiles help in preventing clogging of drainage systems?

- Geotextiles help in preventing clogging of drainage systems by acting as a barrier that filters out fine particles from infiltrating the system. These textile materials allow water to pass through while retaining soil particles, preventing them from clogging the drains and compromising the system's effectiveness.

- Q: I was just doing anti-seepage film and geotextile clerk do not know how to find this project? add me

- Where are you from?

- Q: What is the lifespan of geotextiles?

- The lifespan of geotextiles can vary depending on several factors such as the quality of the material, environmental conditions, and the intended application. Generally, geotextiles are designed to have a lifespan ranging from a few years to several decades.

- Q: Precautions for Polyester Filament Geotextiles

- 1. Geotextiles can only be cut with a geotextile (hook knife), such as in the field of cutting, other materials to take special protective measures to prevent the cutting of geotextiles and its unnecessary damage; Laying geotextile at the same time, must take all necessary measures to prevent damage to the following layer of material; 3. In the laying of geotextiles, we must pay attention not to let the stone, a lot of dust or moisture may damage the geotextile, Drains or filters, or materials that may cause difficulties for subsequent connections to enter beneath geotextiles or geotextiles; 4. After installation, visualize all geotextile surfaces to identify all damaged landlords Marking and repairing, to determine the laying of the surface can not cause damage to foreign substances, such as broken needle and other foreign body; 5. Geotextile connection must follow the following provisions: Under normal circumstances, the slope can not have a horizontal connection (connection along the slope The contours do not intersect with them), except where the patch is located. 6. If the use of suture, suture should be used with geotextile material the same or more than the material, suture should be anti-chemical UV material holding. Suture and geotextile should have a significant color difference in order to facilitate inspection. 7. Special attention to suturing during installation to ensure that no gravel in the soil or gravel cover is in the middle of the geotextile.

- Q: Polyester geotextile filter layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, traces of the tube of the river alone sweeping the beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied In a wider area.

- Q: How do geotextiles contribute to the cost-effectiveness of construction projects?

- Geotextiles contribute to the cost-effectiveness of construction projects by providing various benefits. They act as a barrier against soil erosion, reducing the need for expensive erosion control measures. Geotextiles also enhance soil stability, allowing for the use of less expensive and readily available fill materials. Additionally, they improve drainage and filtration, minimizing the need for costly drainage systems. Overall, geotextiles help optimize construction processes, reduce material and labor costs, and extend the lifespan of structures, making them a cost-effective choice for construction projects.

Send your message to us

Mirafi Woven Geotextile Fabric - PP Non-Woven Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords