PP Fabric Spunbond Nonwoven Fabric Waste Recycling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

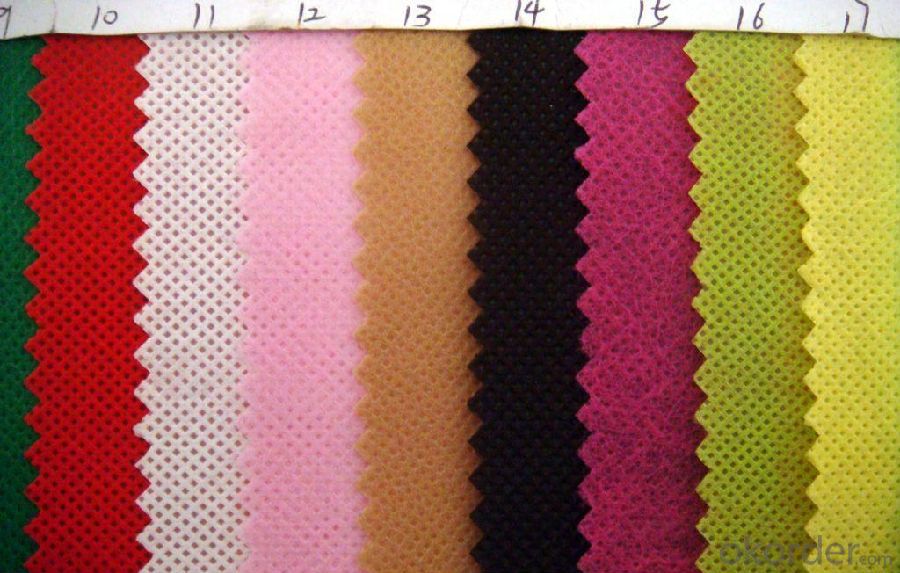

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

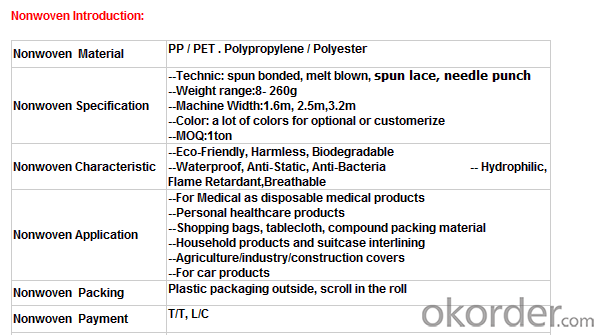

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Application of Biological Enzyme in Textile Processing

- The application of new enzymes in textile processing: the position of chemical synthetic fibers and slurries in the textile is obvious, these polymer can not be biodegradable and degraded, causing environmental pollution, the current researchers are studying the new enzyme

- Q: Textile fabric classification, dyeing and finishing processing is what?

- You talk about the details of the Yeah, textile fabrics are divided into two categories: knitted fabrics and woven fabrics, as well as non-woven I do not know count, huh, huh

- Q: Textile raw materials of mineral fiber

- The preparation of chemical fibers, usually the first natural or synthetic polymer or inorganic materials made of spinning melt or solution, and then filtered, measured by the spinneret (plate) out into a liquid stream, then Solidified into fibers. At this time the fiber is called the primary fiber, its mechanical properties are poor, must go through a series of post-processing processes to meet the textile processing and use requirements.

- Q: Are hats a class of textile and apparel products?

- Hats are popular for textile products, processing or general trade.

- Q: What are the problems with the transformation and upgrading of the processing trade of textile enterprises?

- Especially in the second half of the international financial crisis is a great impact on the textile and garment export market. Textile enterprises are faced with unprecedented difficulties and challenges. February the State Council adopted the "textile industry restructuring and revitalization plan", the purpose is to actively respond to the current international financial crisis

- Q: The Factors Affecting the Capillary Effect of Textile Garment

- Capillary effect referred to as the effect of wool, textile applications terminology, is the characterization of fabric after pre-processing, the wettability of the measured

- Q: DTY FDY POY What are the textile raw materials?

- POY: pre-oriented wire, full name: PRE-ORIENTED YARN or PARTIALLY ORIENTED YARN. Refers to an incomplete stretch of synthetic filaments obtained between high-speed and non-oriented and drawn yarns obtained by high-speed spinning. Compared with the undrawn yarn, it has a certain degree of orientation, good stability, often used as tensile false twisted yarn (DTY) of the special wire. (Generally not used for weaving)

- Q: Why can the oil industry be used as raw materials for the textile industry?

- Commonly used textile industry raw materials are: polyester: polystyrene dicarboxylate; nylon: polyamide fiber; polypropylene: acrylic fiber; acrylic: polyacrylonitrile fiber; polyvinyl chloride: polyvinyl chloride; vinylon: polyvinyl alcohol shrink Aldehyde fiber; aramid: poly (p-phenylene terephthalamide).

- Q: Today, the national textile market prospects

- 2009 is known as the most difficult winter of China's textile industry in the new century, but in this winter, the textile enterprises are not afraid, more is relying on national policy support and self-adjustment to achieve the adverse trend

- Q: Jiangsu Province, more than a large number of textile and garment industry

- Nantong textile industry has a long history, after more than 100 years of development, has a certain scale, a wide range, and the product grade increased year by year, forming a relatively supporting industrial system

Send your message to us

PP Fabric Spunbond Nonwoven Fabric Waste Recycling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords