PP Biaxial Geogrids for Tree Protection W*L3.95*50m/Roll for Soil Reinforcement and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Biaxial Geogrid W*L3.95*50m/roll for Soil Reinforcement and Civil Engineering Project

1.Functions of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

1)Strengthen the load capacity of roadbed or land base and extend the lifetime;

2)Can protect the road surface sinkage or crack;

3)Building convenience, save time and labour, shorten the time limit of project and reduce the charges of maintenance;

4)Can keep the culvert away from the crack;

5)Strengthen the land slope, keep the land away from running off.

6)Reduce the thickness of cushion, reduce the cost;

7)Support the grass to stability for land slope

2. Technical Sheet of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

ITEM | TGSG25-25 | TGSG20-20 | TGSG30-30 | TGSG35-35 | TGSG40-40 |

WIDTH (M) | 3.95 or 4.0+/-0.2 | ||||

TENSILE STRENGTH (≥KN/m) IN LONGITUDIANAL | 25 | 20 | 30 | 35 | 40 |

TENSILE STRENGTH (≥KN/m) IN TRANSERSAL | 25 | 20 | 30 | 35 | 40 |

ELONGATION AT MAX STRAIN(≤%) IN LONGITUDIANAL | 15 | ||||

ELONGATION AT MAX STRAIN(≤%) IN TRANSERSAL | 13 | ||||

TENSILE STRENGTH AT 2% STRAIN(≥KN/m) IN LONGITUDIANAL | 8.75 | 7 | 10.5 | 12.50 | 14 |

TENSILE STRENGTH AT 2% STRAIN(≥KN/m) IN TRANSERSAL | 8.75 | 7 | 10.5 | 12.50 | 14 |

TENSILE STRENGTH AT 5% STRAIN(≥KN/m) IN LONGITUDIANAL | 17.50 | 14 | 21 | 25 | 28 |

TENSILE STRENGTH AT 5% STRAIN(≥KN/m) IN TRANSERSAL | 17.50 | 14 | 21 | 25 | 28 |

CARBON BLACK CONTENT | 2% | ||||

ROLL SIZE | 3.95*50M or 4*50m AS ONE ROLL | ||||

MESH SIZE | APPROX. 40*40MM | ||||

3. Application of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

Highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

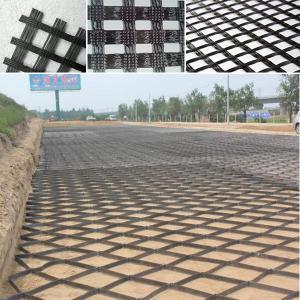

4. Product Show of Hot Sale High Quality PP Biaxial Geogrid 3.95*50m/roll for Soil Reinforcement

- Q: Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are commonly used in landfill capping systems to provide reinforcement and stability to the cover materials. They help distribute loads and reduce stress on the cover system, improving its integrity and performance.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their stability, reducing rutting and cracking, and increasing their overall lifespan. They act as a reinforcement layer within the pavement structure, distributing and transferring the load more efficiently. This helps to minimize pavement deformations and increase resistance to fatigue and shear stresses. Geogrids also restrain the lateral movement of aggregate particles, preventing their displacement and improving the pavement's resistance to lateral spreading and cracking.

- Q: What are the installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, mechanical connection, and soil confinement. Direct placement involves laying the geogrid directly on the ground and securing it with stakes or pins. Mechanical connection involves connecting the geogrid to other materials, such as retaining walls or slopes, using connectors or anchor systems. Soil confinement involves placing the geogrid within a layer of soil to improve its stability and strength. The specific installation method used depends on the specific project requirements and conditions.

- Q: Can geogrids be used in reinforcement of rock slopes?

- Yes, geogrids can be used in the reinforcement of rock slopes. Geogrids are commonly used in geotechnical engineering to enhance the stability and strength of slopes, including rock slopes. They provide additional tensile strength to resist potential movement and erosion, improving the overall stability of the slope.

- Q: Are geogrids effective in preventing soil erosion on slopes with vegetation?

- Yes, geogrids are effective in preventing soil erosion on slopes with vegetation. Geogrids provide reinforcement and stabilization to the soil, preventing it from being washed away during heavy rainfall or strong winds. They also help improve the overall stability of the slope, reducing the risk of soil erosion and maintaining the integrity of the vegetation cover.

- Q: Longitudinal and transverse tensile strength more than 60kn/m which has several geogrid

- The key depends on which side you choose, the choice is different.

- Q: What are the design guidelines for geogrid-reinforced retaining walls?

- The design guidelines for geogrid-reinforced retaining walls include factors such as the type and strength of the geogrid, wall height, soil properties, and loading conditions. The design should ensure proper connection between the geogrid and the wall structure, adequate embedment of the geogrid in the soil, and appropriate spacing and orientation of the geogrid layers. Additionally, the guidelines may cover construction techniques, stability analysis, and considerations for drainage and backfill materials.

- Q: Can geogrids be used in reinforced earth bridge piers?

- Yes, geogrids can be used in reinforced earth bridge piers. Geogrids are commonly used as reinforcement materials in soil structures, including bridge piers. They help improve the stability and strength of the soil, enabling it to withstand the loads and pressures exerted on the bridge piers.

- Q: Fiberglass grille price?

- Glass fiber geogrid, also known as fiberglass geogrid, fiberglass geogrid, is a kind of geogrid, mainly used for asphalt pavement, asphalt pavement to prevent cracks.

- Q: Do geogrids reduce the amount of fill material required?

- Yes, geogrids do reduce the amount of fill material required.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

PP Biaxial Geogrids for Tree Protection W*L3.95*50m/Roll for Soil Reinforcement and Civil Engineering Projects

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords