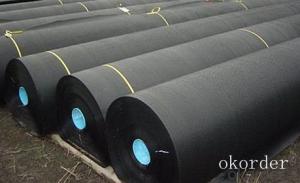

Silt Fence Geotextile Polyvinyl Chloride Geomembrane Environmental Engineering with Best Quality Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geomembrane with impermeable plastic film as a substrate, and non-woven geotextile composite made of impermeable material, which depends on the seepage properties of a impermeable plastic film performance. Is a kind of polymer chemistry flexible material, the proportion of small, extensible stronger ability to adapt to high deformation. Corrosion resistance, low temperature, frost good performance. Have better resistance to erosion, are not afraid of acid, alkali and salt erosion.

Thickness:

1mm-3mm

Length:

50-200m as customers' request

Width:

4m~9m

Standard:

ISO, CE

Feature:

Chemical Resistant

Surface:

Textured Surface

Product name:

hdpe geomembrane manufacturers

Keyword:

hdpe geomembrane manufacturers

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in mining operations?

- Yes, geotextiles can be used in mining operations. Geotextiles are commonly used in mining to reinforce soil and prevent erosion, control sedimentation, and provide stability to slopes and embankments. They are also used for filtration, drainage, and separation purposes in mining applications.

- Q: Geotextile, one ton, replaced by a square meter how much money formula

- How many grams of geotextile

- Q: Can geotextiles be used in subsurface drainage applications?

- Yes, geotextiles can be used in subsurface drainage applications. They are often used as a filter or separator in drainage systems to prevent soil particles from clogging the drainage pipes or channels while allowing water to pass through. Geotextiles can enhance the effectiveness and longevity of subsurface drainage systems by preventing soil compaction and maintaining the flow of water.

- Q: Construction Method of Sand and Gravel Cushion on Slope Soil Geotextile

- Online to find some relevant construction methods, Google library on a lot. After downloading, modify, targeted to add that is the slope of geotextile sand and gravel cushion construction method.

- Q: Can geotextiles be used in landscaping?

- Yes, geotextiles can be used in landscaping. They are commonly used in various landscaping applications such as weed control, erosion control, ground stabilization, and separation of different soil layers. Geotextiles help to improve the overall performance and durability of landscaped areas.

- Q: How are geotextiles used in slope stabilization?

- Geotextiles are commonly used in slope stabilization to reinforce and stabilize the soil, preventing erosion and landslides. They are often installed as a layer between the soil and vegetation or as a part of retaining walls. The geotextiles act as a barrier, distributing the load and improving the soil's strength, while allowing water to drain through and reducing hydrostatic pressure. This helps to maintain the stability of slopes, especially in areas prone to heavy rainfall or steep gradients.

- Q: How do geotextiles affect groundwater flow?

- Geotextiles can either enhance or restrict groundwater flow depending on their permeability and installation method. Permeable geotextiles can allow water to infiltrate through them, facilitating groundwater recharge and promoting natural drainage. Conversely, impermeable geotextiles can prevent water from passing through, altering the natural flow of groundwater and potentially causing waterlogging or surface runoff issues. The selection and proper installation of geotextiles are crucial to ensure they positively impact groundwater flow and maintain the hydrological balance of an area.

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production include energy consumption during manufacturing, emissions of greenhouse gases, water and air pollution from chemical processes, and the generation of solid waste. However, compared to traditional construction materials, geotextiles have lower environmental impacts in terms of resource consumption, carbon emissions, and waste generation.

- Q: Where can the general use of geotextile water can be bought

- Lingxian geotextile manufacturers, welcome to visit

- Q: Geotextile construction inspection batch ye do?

- Plastic woven category: the same formula, the same specifications of 100,000 square meters of products for a group; less than 100,000 square meters, the actual number of a batch. Non-woven geotextiles: the same frequency of production of the same specifications for a number of products; batch volume can be accumulated 100 volumes for a group, but the week is still less than 100 volumes of output, then with a group of output. Plastic woven cloth: batch as a unit, each batch of products randomly take 3 volumes as a sample geotextile categories: each batch of products randomly selected 2% to 3%, but not less than 2 volumes. Sample requirements: the whole width, length 3m or more, the sample can be rolled up, but can not be folded.

Send your message to us

Silt Fence Geotextile Polyvinyl Chloride Geomembrane Environmental Engineering with Best Quality Polypropylene

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords