Mirafi 140n High Strength Polypropylene Geotextile Hot Seal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Polypropylene High Strength Geotextile Hot Seal

Geotextile Description

Filament yarn with polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the process of needle, also without heat treatment, is environmentally friendly building materials.Can replace the traditional engineering materials and construction methods, construction is more secure, and contribute to environmental protection, can be more economic, effective and lasting to solve basic problems in engineering construction.

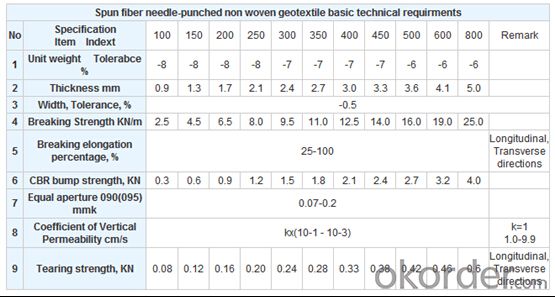

Geotextile Specification

Geotextile Property:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation.

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function.

Geotextile Application:

1. Water conservancy project and hydropower project.

2. Road paving, railway.

3. Airport and port.

4. River bank protection and tunnel

5. Environmental protection, etc.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the different installation methods for geotextiles?

- There are several installation methods for geotextiles, including direct placement, trenching, and mechanical installation. In direct placement, the geotextile is simply laid over the desired area and secured in place with stakes or sandbags. Trenching involves digging a trench and placing the geotextile in the trench before backfilling. Mechanical installation utilizes specialized equipment, such as a geotextile roller or a geotextile gun, to install the geotextile quickly and efficiently. The choice of installation method depends on the specific project requirements and site conditions.

- Q: What are the advantages of using geotextiles in waste containment systems?

- Geotextiles offer several advantages in waste containment systems. Firstly, they act as a barrier, preventing the migration of pollutants and contaminants into the surrounding environment. This helps to protect groundwater and nearby ecosystems from potential harm. Additionally, geotextiles enhance the stability and structural integrity of waste containment systems, reducing the risk of failure or leakage. They also aid in the filtration and drainage of liquids, allowing for proper waste management and preventing the buildup of excess moisture. Overall, geotextiles provide an effective and environmentally-friendly solution for waste containment, ensuring safer disposal of waste materials.

- Q: Production of geomembrane equipment which are such as the production of geotextile need to press machine, open charter, carding machine, etc.

- Mixing machine, screw extruder, heating die, circulating fan, traction machine, into a roll machine.

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering applications for their ability to provide stability, filtration, and separation. When placed correctly, geotextiles can enhance the strength and durability of bridge abutments by distributing load, preventing soil erosion, and improving overall stability.

- Q: Geomembrane bag bag is geomembrane or geotextile

- Neither is the geotextile bag made of woven cloth

- Q: What are the key considerations for geotextile installation in corrosive environments?

- Some key considerations for geotextile installation in corrosive environments include selecting a geotextile material that is resistant to corrosion, ensuring proper installation techniques to prevent exposure of the geotextile to corrosive substances, and monitoring the condition of the geotextile regularly to detect any signs of corrosion or degradation. Additionally, it is important to consider the potential impact of the corrosive environment on the overall performance and lifespan of the geotextile.

- Q: Can geotextiles be used in geotechnical engineering projects?

- Yes, geotextiles can be used in geotechnical engineering projects. Geotextiles are engineered fabrics that are commonly used to reinforce soil, separate different soil layers, and provide filtration and drainage in various geotechnical applications. They can improve the stability, strength, and performance of soil structures, such as retaining walls, embankments, and roadways, by effectively managing water flow and soil interactions.

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. Geotextiles are often used as a separation layer between the growing media and the drainage layer in green roof systems. They help to prevent the mixing of different layers, while still allowing water to drain through. Additionally, geotextiles can also be used to reinforce the root barrier in green roof systems, providing added stability and protection.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are typically tested for strength and durability through various methods such as tensile strength tests, puncture resistance tests, tear resistance tests, and UV stability tests. These tests help determine the geotextiles' ability to withstand different forces, environmental factors, and potential wear and tear, ensuring their quality and performance in different applications.

- Q: What are the applications of geotextiles?

- Geotextiles have various applications in civil engineering and construction projects. They are commonly used for soil stabilization, erosion control, filtration, drainage, and reinforcement purposes. Geotextiles can be found in road and railway construction, landfills, coastal protection, retaining walls, and even in agriculture for weed control and soil improvement.

Send your message to us

Mirafi 140n High Strength Polypropylene Geotextile Hot Seal

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords