Plastic Sheets - China Foam Board Factory:PS Foam Board, PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

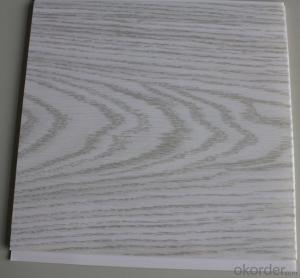

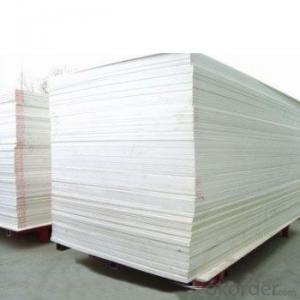

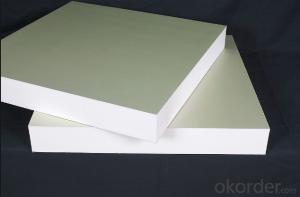

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

Specifications

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware.

The PVC foam board is made through foaming and pressing into shape with additive.

It is widely used in Sanitaryware, Building material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection.

4. Sanitarywares, kitchen cabinet, washroom cabinet.

5.Advertisment

6.Contruction

FAQ

1, How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect

2, Which factors can be customized?

Answer: Material, Color, Size, Packing ,Brand, delivery

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee

pictures

- Q: Can plastic sheets be cut or shaped easily?

- Yes, plastic sheets can be cut or shaped easily using various tools and techniques such as saws, knives, laser cutting, or thermoforming methods.

- Q: Are plastic sheets resistant to impact from hail?

- Yes, plastic sheets are generally resistant to impact from hail due to their flexibility and durability. However, the level of resistance may vary depending on the thickness and quality of the plastic used.

- Q: They need to be non-adhesive.

- Spray it with acrylic wax

- Q: Can plastic sheets be used for making stencils?

- Yes, plastic sheets can be used for making stencils. The flexibility and durability of plastic sheets make them ideal for tracing and cutting out intricate designs. They can be easily cleaned and reused, making them a popular choice for stencil making.

- Q: Are plastic sheets resistant to scratches?

- Yes, plastic sheets are generally resistant to scratches due to their durable and tough nature. However, the level of scratch resistance may vary depending on the type and quality of the plastic sheet.

- Q: Can plastic sheets be used for automotive applications?

- Yes, plastic sheets can be used for automotive applications. They are commonly used for interior components such as dashboards, door panels, and seat backs. Additionally, plastic sheets are used for exterior parts like fenders, bumpers, and trims. Plastic sheets offer advantages such as lightweight, durability, and flexibility, making them suitable for various automotive applications.

- Q: Which type of glue or past to past 2 plastic sheet.{ recycle sheet}to start a small Business

- We need to know what you're going to do with the plastic sheets and what type of sheets they are. Different glues for different requirements.

- Q: Why should the aluminum-plastic composite board retain the polyethylene plastic not less than 0.3mm thick when cutting the inner aluminum sheet and polyethylene plastic?

- Accurately stated, aluminum plate in the opening processing, not cutting, but behind the groove.

- Q: I found the perfect thickness of plastic Delrin in my garage but it's already shaped in an exact circle. The Diameter is 4 inches which is fine because I need 3.89 inch diameter in the pieces I'm cutting. I have approx. 75.3 inches of length of the delrin. Each of the pieces is really thin that I'm creating a mear .03125 inches. I need 324 pieces and a couple to spare wouldn't hurt. Does anyone know how to calculate this or is there a calculator that does this?

- Confusing question, but I think I understand what you need. There are yield calculators out there on the internet, but I will do the math for you. You would get 327 pieces of 4 diameter discs that are .03125 thick. The reason it wouldn't be more is that the saw blade will eat up material in between each cut (about .2 per cut) Just so you know, this job will be VERY difficult to do, so make sure you have proper machinery or take it to a professional. Good luck!

- Q: In the stores, adhesive scrapbooking embellishments are usually stuck to a clear sheet of plastic in their packaging. What is this material and where can you find it in bulk or large sheets that can be cut down. Someone told me to try acetate (transparencies), but the adhesive stuck permanently to that material and could not be easily removed. Are there different kinds of acetate or is there something different I need to be using? I have a product that needs to be stuck to this material and this product will be sold so it must look professional...so don't tell me to tear the plastic out of my kid's Barbie doll packaging.

- I think that what you are looking for is called release paper, or release liner. You might also want to look for glassine release paper. Alternatively, some sprays might be available for you to make any or most papers into release film. Wax paper is also commonly used and more readily available, although you will not get that clear professional effect you want. I have added a couple of links for more information.

Send your message to us

Plastic Sheets - China Foam Board Factory:PS Foam Board, PVC Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords