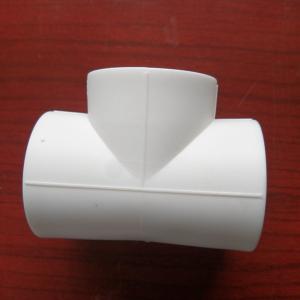

Plastic Pipe Push Fittings PPR Reducing Tee for Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PPR Reducing Tee Plastic Pipe Fittings

Mainly used to connect civil construction, industrial, agricultural and landscape irrigation drainage system PE pipes

Main Features of PPR Reducing Tee Plastic Pipe Fittings

1, health, non-toxic: the various parts of the pipeline system consists of PP-R pipes and fittings constituted can be completely non-toxic, health indicators in line with GB / T17219 standards.

2, does not rust: PH value can withstand a wide temperature range, in the range of 1 to 14, a high concentration of acid and alkali corrosion.

3, wear-resistant, non-fouling: PP-R pipe and tube inner wall smooth, uniform flow resistance is small and does not scale.

4, reducing vibration and noise: PP-R pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

5, anti-cracking: PP-R materials excellent elasticity makes pipes and fittings sectionally With frost expansion of the liquid together without bursting.

6, anti-condensation, heat loss is small: PP-R material is a poor thermal conductor, reduces condensation and reduce heat loss less.

7, anti-electric corrosion: PP-R material is a poor conductor of electricity can avoid corrosion. Complete specifications: 10-30 optional

Pictures of PPR Reducing Tee Plastic Pipe Fittings

- Q: Can plastic pipe fittings be used for solar thermal systems?

- Yes, plastic pipe fittings can be used for solar thermal systems. Plastic pipe fittings, specifically those made from materials such as PVC or CPVC, are commonly used in solar thermal systems due to their durability, corrosion resistance, and affordability. These fittings can effectively handle the temperature and pressure requirements of solar thermal systems, making them a suitable choice for connecting and directing the flow of water or heat transfer fluids in such systems.

- Q: How do plastic pipe fittings compare to nylon fittings?

- Plastic pipe fittings and nylon fittings have their own advantages and limitations. Plastic pipe fittings are generally more affordable and offer a wider range of options in terms of sizes and shapes. They are also resistant to corrosion, easy to install, and have good chemical resistance. On the other hand, nylon fittings are known for their exceptional strength and durability, making them suitable for high-pressure applications. Nylon fittings also have excellent resistance to chemicals, UV rays, and heat. Ultimately, the choice between plastic pipe fittings and nylon fittings depends on the specific requirements of the application and the desired properties of the fittings.

- Q: Can plastic pipe fittings be used for swimming pool systems?

- Yes, plastic pipe fittings can be used for swimming pool systems. Plastic pipe fittings, such as PVC or CPVC, are commonly used in swimming pool systems due to their durability, corrosion resistance, and affordability. These fittings are designed to withstand the water and chemical environments typically found in swimming pools, making them a suitable choice for pool plumbing systems.

- Q: Can plastic pipe fittings be used for agricultural irrigation systems?

- Yes, plastic pipe fittings can be used for agricultural irrigation systems. Plastic fittings are commonly used in these systems due to their durability, cost-effectiveness, and resistance to corrosion and chemicals. Additionally, plastic fittings are lightweight and easy to install, making them suitable for various agricultural irrigation applications.

- Q: What types of plastic are commonly used for pipe fittings?

- Common types of plastic used for pipe fittings include polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polypropylene (PP), and high-density polyethylene (HDPE).

- Q: Can plastic pipe fittings be used for irrigation systems in agricultural fields?

- Yes, plastic pipe fittings can be used for irrigation systems in agricultural fields. They are commonly used due to their durability, cost-effectiveness, and resistance to corrosion. Additionally, plastic pipe fittings are lightweight, easy to install, and allow for flexibility in designing and modifying irrigation systems as per specific field requirements.

- Q: Do plastic pipe fittings have a maximum operating temperature?

- Yes, plastic pipe fittings have a maximum operating temperature. The maximum temperature varies depending on the type of plastic used in the fittings. It is important to consult the manufacturer's specifications to ensure that the fittings are compatible with the intended temperature range.

- Q: How do plastic pipe fittings compare to polypropylene fittings?

- Plastic pipe fittings and polypropylene fittings are both types of plastic fittings commonly used in plumbing systems. However, there are some differences worth noting. Plastic pipe fittings are a broad category that includes fittings made from various types of plastic materials, such as PVC, CPVC, and ABS. On the other hand, polypropylene fittings are specifically made from polypropylene, a thermoplastic polymer known for its high chemical resistance and durability. In terms of performance, polypropylene fittings generally offer superior chemical resistance, making them more suitable for applications involving corrosive or aggressive fluids. They are also known for their high temperature resistance and mechanical strength. Plastic pipe fittings, on the other hand, can vary in terms of quality and performance depending on the specific material they are made from. Another important aspect to consider is the ease of installation. Both plastic pipe fittings and polypropylene fittings are typically designed for solvent welding or using mechanical connections. However, polypropylene fittings often have a more precise and secure fit due to their tighter tolerances, which can simplify the installation process and reduce the risk of leaks. Ultimately, the choice between plastic pipe fittings and polypropylene fittings depends on the specific application requirements, such as the type of fluid being transported, the temperature and pressure conditions, and the chemical compatibility needed. It is important to consult with professionals or follow the manufacturer's recommendations to ensure the right choice for each individual case.

- Q: How do you connect plastic pipe fittings to polybutylene pipes?

- To connect plastic pipe fittings to polybutylene pipes, you can use push-fit fittings specifically designed for polybutylene piping. These fittings have a built-in grip ring that securely holds onto the pipe when it is pushed into the fitting, creating a watertight seal. No additional tools or soldering are required, making it a quick and easy method for connecting plastic pipe fittings to polybutylene pipes.

- Q: Are plastic pipe fittings suitable for use in wineries and breweries?

- Yes, plastic pipe fittings are suitable for use in wineries and breweries. They are commonly used in these industries due to their corrosion resistance, durability, and ease of installation. Plastic fittings are also compatible with a wide range of chemicals and can withstand the high temperatures and pressures often encountered in winemaking and brewing processes.

Send your message to us

Plastic Pipe Push Fittings PPR Reducing Tee for Landscape Irrigation Drainage System

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords