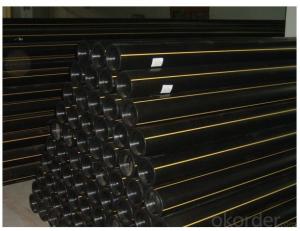

Plastic Pipe --- PE Gas Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of PE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

Product Description of PE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

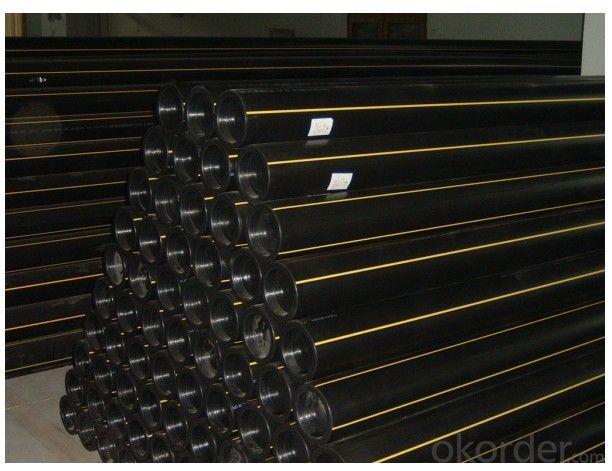

Advantage of PE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

- Q: What is the standard length of steel pipes?

- The standard length of steel pipes can vary depending on the application and industry, but commonly they are available in lengths of 20 feet or 6 meters.

- Q: What are the factors that affect the pressure rating of steel pipes?

- There are several factors that can affect the pressure rating of steel pipes. 1. Material strength: The strength of the steel used in the pipe construction plays a crucial role in determining its pressure rating. Higher strength steel can withstand higher pressure levels, whereas weaker grades of steel may have lower pressure ratings. 2. Wall thickness: The thickness of the pipe wall directly impacts its pressure rating. Thicker walls can handle higher pressure levels as they provide more resistance against the internal forces exerted by the fluid or gas flowing through the pipe. 3. Pipe diameter: The diameter of the steel pipe also influences its pressure rating. Generally, larger pipes have higher pressure ratings as they have a larger cross-sectional area to distribute the internal pressure forces. 4. Temperature: Elevated temperatures can significantly affect the pressure rating of steel pipes. High temperatures can weaken the steel material, reducing its overall strength and, consequently, its pressure rating. Therefore, it is important to consider the maximum operating temperature when determining the pressure rating of steel pipes. 5. Corrosion resistance: Corrosion can weaken the pipe material over time, leading to a decrease in its pressure rating. Various factors such as the type of fluid being transported, pH levels, and environmental conditions can impact the corrosion resistance of steel pipes. Utilizing corrosion-resistant coatings or selecting stainless steel pipes can help mitigate this factor. 6. Manufacturing standards: Compliance with recognized industry standards and specifications is crucial in determining the pressure rating of steel pipes. These standards ensure that the pipes are manufactured using proper techniques and materials, providing reliable and accurate pressure ratings. 7. External loads: External loads or forces acting on the pipes, such as soil settlement, traffic loads, or installation practices, can affect their pressure rating. Proper design and installation techniques, including adequate support and protection, are essential in ensuring the pipes can withstand these external forces without compromising their pressure rating. It is important to consider all these factors and consult relevant industry standards and guidelines to determine the appropriate pressure rating for steel pipes in different applications.

- Q: How are steel pipes measured and labeled?

- Steel pipes are typically measured and labeled based on their nominal pipe size (NPS), which refers to the inner diameter of the pipe. This measurement is expressed in inches or millimeters. Additionally, steel pipes are often labeled with their schedule or wall thickness, which is represented by a numerical value. The labeling also includes the pipe material, such as carbon steel or stainless steel, and may include other specifications and markings as required by industry standards and regulations.

- Q: Can steel pipes be insulated for thermal efficiency?

- Steel pipes can indeed be insulated to enhance their thermal efficiency. By insulating steel pipes, heat loss or gain can be minimized, depending on the specific purpose. Typically, the insulation material is wrapped around the pipes, creating a protective barrier. This barrier effectively prevents heat transfer between the pipes and the surrounding environment. As a result, the energy required to heat or cool the fluid flowing through the pipes is significantly reduced, leading to improved energy efficiency. This practice is widely employed in industries such as HVAC, oil and gas, and industrial processes, where precise temperature control is crucial. Moreover, insulation also serves to prevent condensation and corrosion on the outer surface of the pipes. All in all, insulating steel pipes is a cost-effective measure that enhances thermal efficiency and reduces energy consumption.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: Can steel pipes be used for transporting gases?

- Yes, steel pipes can be used for transporting gases. Steel pipes are commonly used for gas transportation due to their high strength, durability, and resistance to corrosion. They can effectively withstand high pressure and temperature conditions, making them a reliable choice for gas transmission systems.

- Q: What are the different factors affecting the flow rate of steel pipes?

- There are several factors that can affect the flow rate of steel pipes, including the diameter and length of the pipe, the viscosity and temperature of the fluid being transported, the pressure difference across the pipe, and any obstructions or irregularities in the pipe's interior surface. Additionally, the type of fluid being transported and its flow characteristics, such as laminar or turbulent flow, can also impact the flow rate of steel pipes.

- Q: What is galvanized steel pipe?

- Galvanized steel pipe is a type of steel pipe that has been coated with a layer of zinc to protect it from corrosion. This process involves immersing the steel pipe in a molten zinc bath, which creates a protective barrier on the surface of the pipe. The zinc coating helps to prolong the lifespan of the steel pipe, making it resistant to rust and other forms of corrosion. Galvanized steel pipes are commonly used in plumbing, water supply, and construction applications.

- Q: Can steel pipes be used for bridge construction?

- Yes, steel pipes can be used for bridge construction. Steel pipes are commonly used in bridge construction due to their high strength, durability, and ability to withstand heavy loads. They offer excellent structural support, making them suitable for various bridge components such as piers, columns, and beams. Additionally, steel pipes can be easily fabricated, transported, and assembled, making them a popular choice in the construction industry.

- Q: How do you calculate the pipe flow velocity for steel pipes?

- To calculate the pipe flow velocity for steel pipes, you can use the formula: Velocity = (Flow rate / (π * (Diameter/2)^2)). This equation takes into account the flow rate of the fluid through the pipe and the diameter of the steel pipe.

Send your message to us

Plastic Pipe --- PE Gas Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords