Mactex Geotextile Plastic Gravel Stabilizer/Soil Stabilizer Geocell/Grass Soil Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Gravel Stabilizer:

strength geosynthetics, which is popular in domestic and abroad. It is a kind of three-dimensional network structure shaped by high-strength HDPE sheets through ultrasonic welding of high strength. Currently, it is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Main Features of Plastic Gravel Stabilizer:

1 Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

2 Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

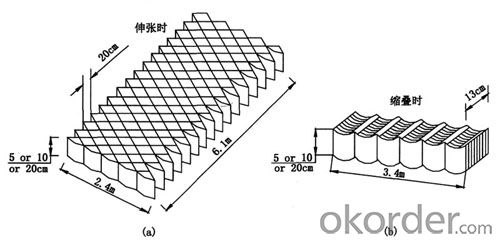

3 Size is relatively stable, change the height and welding distance can meet the needs of different projects.

4 Retractile, easy to transport.

5 Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

6 Can be used repeatedly.

Specifications of Plastic Gravel Stabilizer:

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Remarks: 1. This is a basic technical specification. 2. All of the technical indexes can be reached according to the customers' demand, and the other special standards will be carried out by agreement or contact.

| ||||||

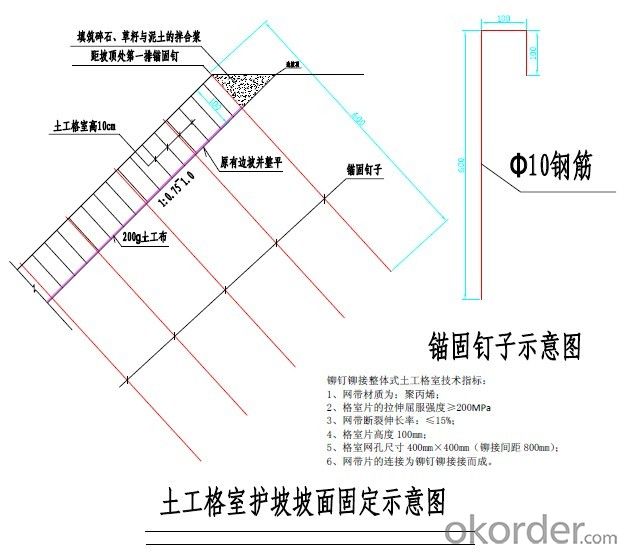

Applications of Plastic Gravel Stabilizer:

1 To stable the roadbed of highway/railway.

2 To bear the load of dyke, retaining wall.

3 To improve the watercourse of shallow river.

4 To support the pipeline and sewer.

5 To be used as independent wall, wharf and breakwater, etc..

6 To be used for the regulation of the desert, beaches, river bed and river bank.

7 Open the superimposed geocell.

8 Fixed with nails or connected with the framework of stretching device.

9 Fill the particle filler until the full and beyond standard room to the top, then vibrate or roll to finish the primary work.

10 At this point, cell chamber system can support all kinds of construction equipment. The construction can be done directly in the above.

IMages of Plastic Driveway Paver Gravel Stabilizer:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geotextiles help in filtration?

- Geotextiles help in filtration by acting as a barrier that allows water to pass through while preventing the passage of fine particles and sediments, effectively filtering the water.

- Q: How can the geotextile extension of 65 to do the following

- I professional production geotextile geomembrane and other geotechnical materials, wish smooth

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- That is, at home and home boundaries to break off. Or can not achieve the effect of waterproof

- Q: How do geotextiles help with erosion control in river channels?

- Geotextiles help with erosion control in river channels by providing a physical barrier that stabilizes the soil and prevents it from being washed away by flowing water. They also promote vegetation growth by allowing water to permeate while filtering out sediment, ultimately protecting the riverbanks from erosion.

- Q: How do geotextiles contribute to the stability of road embankments?

- Geotextiles contribute to the stability of road embankments by providing reinforcement and separation between soil layers. They act as a barrier, preventing the mixing of different soil types and enhancing the load-bearing capacity of the embankment. This helps to distribute the applied loads more evenly, reducing settlement and potential failure. Additionally, geotextiles improve drainage and prevent the loss of soil particles, reducing the risk of erosion and maintaining the embankment's integrity over time.

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: Can geotextiles be used in coastal erosion control projects?

- Yes, geotextiles can be used in coastal erosion control projects. They are often employed as a part of erosion control systems to stabilize the soil and prevent erosion in coastal areas. Geotextiles are permeable fabrics that are placed on the ground or underwater to reinforce and protect the soil, while allowing water to pass through. They can help in maintaining beach profiles, preventing sediment loss, and reducing wave energy, thus providing effective coastal erosion control.

- Q: Geotextile gbt-2008.200g / m2 test standard value

- GB / T-2008 is the national executive standard for filament woven geotextile. 200g / ㎡ of the filament woven geotextile warp rupture strength ≥ 50KN / m, zonal rupture strength of the rupture strength of 0.7-1.0 times the elongation at break ≤ 35% weft ≤ 30% , The width of the deviation of -1.0%, CBR breaking strength ≥ 4.0KN, the equivalent aperture O900.07-0.5mm, the vertical permeability coefficient (1.0 ~ 9.9) × (10 negative square ~ 10 negative five times), tear Breaking strength ≥ 0.8KN, irrigation thickness deviation of ± 8%, length and width deviation of ± 2%, sewing strength ≥ breaking strength × 50% KN / m, which irrigation thickness deviation, length and width deviation, sewing strength only on the mold Bag cloth assessment. Under the GB / T-2008 GB standard.

- Q: How are geotextiles affected by temperature variations?

- Geotextiles are generally resistant to temperature variations and can withstand a wide range of temperatures without significant impact on their performance. However, extreme temperature fluctuations, especially rapid changes, can potentially cause expansion or contraction of the geotextile material. This may lead to changes in its physical properties, such as reduced tensile strength or altered permeability. Overall, while temperature variations can have some effect on geotextiles, it is typically minimal and does not compromise their functionality significantly.

- Q: How do geotextiles help with reinforcement of soil slopes?

- Geotextiles help with the reinforcement of soil slopes by providing stability and preventing erosion. They are placed between layers of soil to distribute the load and strengthen the slope. The geotextiles act as a barrier, separating different soil layers and preventing the movement of fine particles. This helps to improve the overall strength and integrity of the slope, reducing the risk of landslides and soil erosion.

Send your message to us

Mactex Geotextile Plastic Gravel Stabilizer/Soil Stabilizer Geocell/Grass Soil Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords