Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

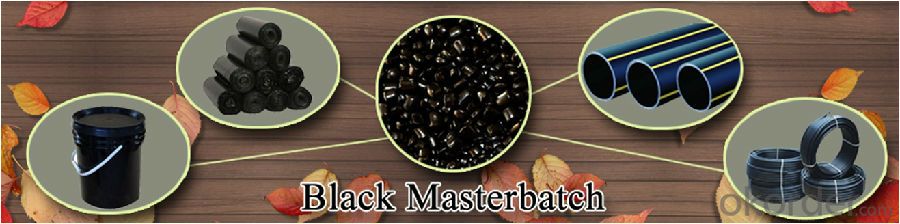

Black masterbatch is made of high tinting strength carbon black and virgin pe resin and additives production

Additive amount:2%-30% is recommended. Or adjust the dosage as per your products performance

Application:Blowing film,injection molding,pipe and wire drawing

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Advantage of Black Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Black Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of Black Masterbatch

- Q: I made of plastic raw materials accessories containing benzene, how to remove the teacher, please enlighten!

- Benzene is generally not used as a plastic processing aid, even if mixed with a little, the plastic molding process in the high temperature also make it has long been volatile.

- Q: Main ingredients and formulations of PPR tubes

- The main ingredient of PPR tube is polypropylene. The formula is simple. It is added color masterbatch. Suggest not to add any calcium powder and so on.

- Q: What is the difference between PA66 and PA6 plastic raw materials? Differences in price, color, performance, etc

- PA66 (polyamide 66 or nylon 66) is more widely used in the automotive industry, instrument shells, and other products that require impact resistance and high strength than PA6, PA66.

- Q: What is the hardness of PAEK+30%GF plastic material?

- Polypropylene plastic (PP) hardness is Rockwell hardness 48. General plastics Rockwell hardness, Brinell hardness and Rockwell hardness measurement, not with Mohs hardness measurement. The hardness of nails is not measured, so it is difficult to compare with the data, I think the hardness should be quite.

- Q: What is the concept of plastic raw materials for turnover containers?

- Plastic turnover box, other features: 1) plastic turnover box outer dimension refers to the maximum size of the logistics box cover. 2) the plastic turnover box has no standard inner concave, and the case size is 18mm. 3) the carrying capacity of a plastic turnover box means that the load is uniformly placed within the range of the environmental temperature. 4) the effective working temperature of the plastic turnover box is -25 DEG C - 40 DEG C. 5) plastic turnover boxes can be stacked for storage, saving space.

- Q: What are the materials for making plastic buckets? How many are there?

- Any theory can be made of plastic barrel type container, but for performance and cost considerations, the vast majority of plastic barrels are polyethylene or polypropylene products, drinking machine bucket is the use of polycarbonate (PC). The specific use of what material, to see what you plan to install.

- Q: What is plastic material E-PET?

- PEI is generally broken piece of edible oil bottle, coke bottles, water bottles and other beverage bottles. Professionally speaking, PET is polyethylene terephthalate, and E-PET refers to high transparency, smooth surface, large bottle thickness, high temperature resistance at 120 degrees Celsius or more. Simply put, it's a PET bottle of good quality. Our jargon is a mineral water bottle.

- Q: How many kinds of plastic raw materials are there? How to distinguish them?

- According to the nature of the plastic after heating, it is divided into thermoplastic and thermosetting plasticsThermoplastic molecular structures are linear structure, softening or melting when heated, plastic into certain shape, after cooling and hardening. When heated to a certain extent to soften after cooling and harden, this process can be repeated several times. Such as polyvinyl chloride, polyethylene, polystyrene and other thermoplastic. Plastic molding process is relatively simple, can continuous production, and has very high mechanical strength, so it is developing very quickly.The molecular structure of thermosetting plastics is the body structure, softening also occurs in heated, can plastic into a certain shape, but is heated to a certain extent or amount of curing agent, hardened stereotypes, re heating become soft and will not change shape. The thermosetting plastic processing molding after heating no softening, and therefore can not be recovered then, such as phenolic, amino plastics, resin and other plastic. These are thermosetting plastic molding process is more complex, so the continuous production is difficult, but its good heat resistance, not easy to deformation, and the price is relatively low.

- Q: What are the materials for making plastic basins? Are they raw materials?

- PP material ah! Usually with raw materials, slightly more mouth material!

- Q: Do you have plastic materials that are low in price instead of ABS?

- The hardness is the same as that of ABS. H series PP contains nucleating agent. The hardness of PP after crystallization is 30% higher than that of ordinary PP, 110R is 109R, and the hardness of ABS is

Send your message to us

Plastic Black Masterbatch Color & Additive Master Batch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords