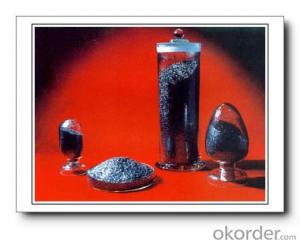

Pinewood Derby Graphite Powder for Refractory Made in China Good Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Natural Flake Graphite:

1.Excellent toughness

2.Self-lubricant, high strength

3.Corrosion resistance

Regular Index of Natural flake graphite:

| Article | Specification | Particle Size(%) | Fixed Carbon | Moisture | |

| Screen Oversize | Screen Undersize | (%) | (%) | ||

| High Carbon | 32Mesh | ≥80 | 94-99 | ≤0.5 | |

| Graphite | 50Mesh | ||||

| 80Mesh | |||||

| 100Mesh | |||||

| 150Mesh | |||||

| -100Mesh | ≥80 | ||||

| -200Mesh | |||||

| -300mesh | |||||

| -500Mesh | |||||

-1000Mesh -5000mesh | |||||

| Intermediate Carbon | 32Mesh | ≥80 | 80-93 | ≤0.5 | |

| Graphite | 50Mesh | ||||

| 80Mesh | |||||

| 100Mesh | |||||

| 150Mesh | |||||

-100Mesh -1000mesh -5000mesh | ≥80 | ||||

Packaging & Shipping of Natural Flake Graphite :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Use of Natural Flake Graphite::

widely applied to high quality fire resistance material and coating of metallurgy industry,hot working material stabilizer of military industry,lead of light industry,carbon brush of electrical industry,electrode of battery industry,and catalyzer and additive of fertilizer industry.After further process,scale graphite can be made into the following high-tech products such as graphite colloidal graphite,graphite compacting material and composite material,graphite products,and graphite anti-friction additive,which are becoming important nonmetal mineral materials in every industry.

- Q: What are the hazards of inhalation of graphite dust?

- It must be harmful to human beings! Look at the dictionary of carbon black dust lung disease Description: black carbon pneumoconiosis: long-term inhalation of carbon black dust caused by pneumoconiosis. Carbon black is mainly the quality of easy flying carbon. Although the production has been closed and automated, the phenomenon of dust flying still exists. Therefore, workers who produce and use carbon black may have black carbon pneumoconiosis, the shortest length of onset is 15 years, the longest can be more than 25 years, the clinical symptoms are mild, and the progress is slow, and generally does not affect the ability to work.

- Q: Thermal conductivity and density of graphite powder

- For the same type of graphite, the thermal conductivity increases with increasing density, and Figure 11 shows the relation between the density of HDFG and the density of the same graphite.The heat treatment temperature of polycrystalline graphite is mostly made by roasting the semifinished material by high temperature heat treatment. The higher the heat treatment temperature is, the more perfect the crystallite growth is, the La increases, and the thermal conductivity also increases. With calcined petroleum coke and coal tar pitch, roasting sticks made of extrusion, after different heat treatment (HTT), the value of La are shown in Table 4. The axial thermal conductivity will change with temperature is shown in figure 12. The reciprocal of thermal conductivity 1/ lambda is called thermal resistance. At different temperatures, the relationship between the axial thermal resistance of graphite is shown in Figure 13 and l/La / 1/.

- Q: Graphite powder screening process, because with static holding together, resulting in vibration screen plugging network how to solve?

- Electrostatic earthing or electrostatic eliminator. In fact, there is a certain conductive graphite powder is very fine, but so long as the electrostatic would slightly have great effect, give you two ways, one is the good grounding conductor can be static vibration sieve, go through a grounding wire guide;

- Q: Is battery capacitor powder dangerous?

- Will pour into the dry drying workshop, drying after bagging, namely ordinary graphite powder, the carbon content of the finished product is an average of 90%. Use to make pencil cores, graphite electrodes for batteries, lubricant features for cable cars, a dark gray, metallic, opaque, flaky solid.

- Q: Is the graphite powder poisonous?

- There are three kinds of substances that fly out of the black spot from the carbon factory:1. Bituminous dust.2. A relatively fine particle of calcined coke (petroleum coke after calcination).3. A fine particle of calcined and graphitized Shi Mofen (calcined coke and bituminous mixture).Both poisonous.

- Q: What is the use of flake graphite in making flake graphite powder?

- Flake graphite is widely used in advanced refractory materials and coatings of metallurgical industry. Such as bricks, crucible etc.. Military industrial explosive materials stabilizer, smelting industrial desulfurization growth agent, light industry, electrical industry pencil brush, industrial battery electrode and catalyst in chemical fertilizer industry, etc.. Flake graphite is further processed and can be used to produce graphite milk. It is used as lubricant, release agent, drawing agent and conductive paint. Expandable graphite can also be used for flexible graphite products, such as flexible graphite seals and flexible graphite composite products.

- Q: How to measure the iron content in graphite powder?

- Take a certain amount of samples, adding dilute hydrochloric acid, excessive filtering and drying. The quality of the filter residue. By weighing the quality of the sample quality is the quality of minus slag containing iron. With this value divided by the sample quality, the mass fraction of iron.

- Q: What is the simple test method for graphite powder used in casting?

- Graphite is carbon,. It can be detected by combustion..

- Q: Why is the battery electrolyte more potassium hydroxide and sodium hydroxide is less used?

- The solution of potassium hydroxide at a density of 1.25~1.27 (15 DEG C) is used at temperatures below -15. For the purpose of taking into account the low temperature performance and the charge holding capacity, the sealed nickel cadmium battery adopts an aqueous solution of potassium hydroxide with a density of 1.40 (15 DEG C). In order to increase the capacity and cycle life of battery, usually adding lithium hydroxide amount in the electrolyte (per litre of electrolyte and 15~20g).

- Q: The axis and drum can use graphite powder lubrication

- No, graphite powder is suitable for high temperature environment, and the lubricating effect is better than that of lubricating oil

Send your message to us

Pinewood Derby Graphite Powder for Refractory Made in China Good Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords