Pet Spunbond Non-Woven Geotextiles with High Stabilization - Geotextile Price in Bangladesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM Geotextile acts similar to a sand filter by allowing water to move through the soil

while retaining all upstream soil particles. CNBM Geotextiles are used to prevent soils

from migrating into drainage aggregate or pipes while maintaining flow through the system.

TexoFib Geotextiles are also used below rip rap and other armour materials in coastal and

river bank protection systems to prevent soil erosion.

filtration

Reinforcement

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

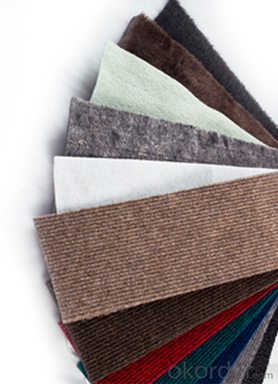

A: Yes, please check the pictures:

- Q: Can geotextiles be used in athletic field construction?

- Yes, geotextiles can be used in athletic field construction. Geotextiles are commonly employed to enhance the stability, drainage, and durability of athletic fields. They can be used for various purposes, including erosion control, soil stabilization, and separation of different soil layers. The use of geotextiles can help improve the performance and longevity of athletic fields, making them a valuable component in their construction.

- Q: Water board and water pipes and quick overburden trees

- Set aside the road to pull the car, little by little to fill the soil, I am specializing in the production of geotextile, drainage board, wish smooth

- Q: What are the specifications for geotextiles in roadways?

- Geotextiles used in roadways should meet certain specifications to ensure their effectiveness. These specifications typically include factors such as tensile strength, puncture resistance, filtration capability, and elongation properties. Additionally, the geotextiles should have appropriate thickness, weight, and permeability to allow for proper drainage and filtration of water. The specifications may vary based on the specific requirements of the road project, but overall, geotextiles in roadways need to be durable, efficient, and capable of enhancing the overall performance and longevity of the road.

- Q: What kind of geotextiles are used in highway geotextiles?

- Highway geotextile general use Hongxiang new material filament geotextile, to overcome the cracks and so on the road defects.

- Q: Can geotextiles be used for reinforcement in landfills?

- Yes, geotextiles can be used for reinforcement in landfills. Geotextiles are commonly used as a geosynthetic material in landfill construction and operation. They are placed within the landfill to improve stability, prevent soil erosion, and enhance the overall strength of the landfill structure. Additionally, geotextiles help to control water flow and filter out contaminants, providing an effective solution for reinforcement in landfills.

- Q: Geotextile mouth chain suture is what kind of picture

- Hello I am a professional geotextile and other geotextile materials,

- Q: How do geotextiles help in soil stabilization?

- Geotextiles help in soil stabilization by acting as a barrier between the soil and other materials, such as water or rocks, preventing erosion and promoting the stability of the soil. They also enhance the soil's mechanical properties, such as strength and load-bearing capacity, by distributing the applied forces more evenly. Additionally, geotextiles can control the filtration and drainage of water, reducing the risk of soil saturation and improving its overall stability.

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer numerous advantages in green building design. Firstly, they provide effective erosion control by stabilizing soil, preventing sediment runoff, and reducing the need for traditional erosion control measures. Additionally, geotextiles enhance water filtration and drainage, promoting healthier soil and preventing waterlogging. These materials also aid in weed control, reducing the need for herbicides and minimizing maintenance efforts. Moreover, geotextiles can improve the structural integrity of green building projects by reinforcing soil and preventing subsidence. Lastly, they offer a sustainable solution as they are typically made from recycled materials and can be reused or recycled themselves.

- Q: What are the different geotextile installation techniques in filtration?

- Some of the different geotextile installation techniques in filtration include direct placement, trench installation, and wrapping. Direct placement involves placing the geotextile directly on the soil surface, while trench installation involves burying the geotextile in a trench or cut. Wrapping technique involves wrapping the geotextile around a structure or pipe to provide filtration. These techniques are used to enhance filtration and prevent soil erosion in various construction and environmental projects.

- Q: How do geotextiles help with filtration in drainage systems?

- Geotextiles help with filtration in drainage systems by acting as a barrier that prevents the passage of fine particles while allowing water to pass through. They effectively filter out sediment, debris, and other contaminants, ensuring that only clean water flows through the drainage system. This helps to maintain the system's functionality and prevent clogging or blockages.

Send your message to us

Pet Spunbond Non-Woven Geotextiles with High Stabilization - Geotextile Price in Bangladesh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords