(PE)Color Coated Sheet-PPGI /Hot Dipped Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.(PE)Color Coated Sheet-PPGI Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of (PE)Color Coated Sheet-PPGI

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGI Metal Building Materials |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

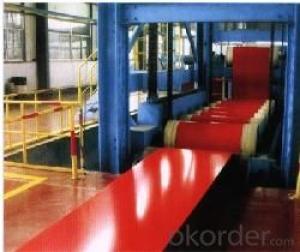

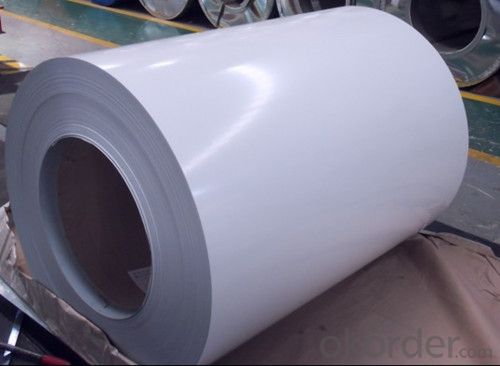

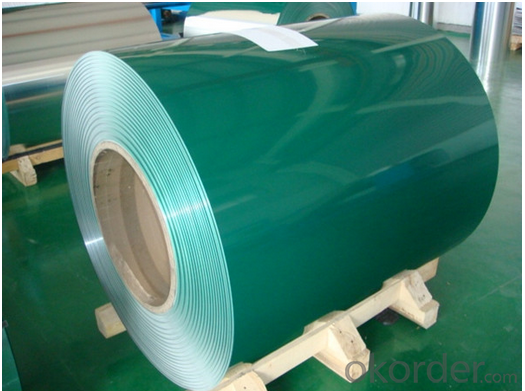

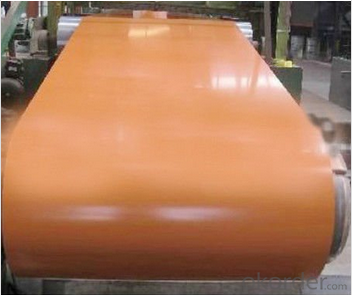

4.(PE)Color Coated Sheet-PPGI image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I have never owned a non-stainless steel chef's knife and have been looking at some to buy recently, but all of them have various degrees of wear and use. They say that the wear is normal for non-stainless steel knives, but how can I tell if it is too much wear, or if the blade is clean?

- cold rolled steel waers as you carve meat. If the blad if to thin you may want a better one. Utica knife in utica N.Y. made them up to about 10 years ago and i still buy them at auctions.

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils can vary depending on the specific requirements and standards of the industry. However, common tolerances for steel coils typically range between +/- 0.005 to 0.020 inches in terms of thickness, width, and length. These tolerances ensure that the steel coils meet the desired specifications and can be used effectively in various applications.

- Q: What is the average tensile strength of a steel coil?

- The average tensile strength of a steel coil can vary depending on the specific grade and type of steel used. However, on average, steel coils tend to have tensile strengths ranging from 300 to 2,000 megapascals (MPa).

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- any pair of larger bolt cutters would whack right thru that lock brother. use it, but put a backup lock on somewhere else too. thx for the pic!

- Q: If you keep it dry and clean, what steel will last the longest over the years with continued use and sharpening?

- you eventually will wear the blade out. i have seen old guys pocketknives that they used for whittlin and the blades have deep curves in them like khukris from wear. i reccommend, 440 stainless, or something with a rockwell hardness rating above 45.

- Q: What is the maximum load capacity for steel coil storage racks?

- The maximum load capacity for steel coil storage racks can vary depending on various factors such as the design, dimensions, and specifications of the rack. It is recommended to consult the manufacturer or supplier for the specific load capacity of the steel coil storage rack you are using.

- Q: Can steel coils be customized?

- Yes, steel coils can be customized to meet specific size, shape, and material requirements of various industries. Customization can include altering the dimensions, thickness, or even the coating of the steel coils to suit specific applications.

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- High carbon steel is much harder than iron. In fact, steel -is- iron with carbon in it. Mild steel has a very low carbon content and is much softer. High carbon steel is much stronger after heat treatment. However, about 2% carbon, it is considered cast iron. Mild steel contains about 0.16% to 0.29% carbon content. It has a relatively low strength but is highly malleable.

- Q: How do steel coils contribute to earthquake resistance in structures?

- Steel coils contribute to earthquake resistance in structures by providing strength and flexibility. When used in the construction of buildings, steel coils can absorb and dissipate the energy generated by an earthquake, preventing it from causing significant damage. The high tensile strength of steel allows it to withstand the lateral forces and vibrations during an earthquake, ensuring the structural integrity of the building. Additionally, the ductility of steel allows it to bend and deform without breaking, further enhancing its ability to withstand seismic activity.

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers minimize waste and maximize efficiency by implementing various strategies such as optimizing production processes, recycling and reusing scrap materials, adopting advanced technologies for energy conservation, and implementing lean manufacturing principles to eliminate unnecessary steps and reduce downtime. They also focus on continuous improvement, employee training, and regular maintenance of equipment to ensure smooth operations and minimize waste generation.

Send your message to us

(PE)Color Coated Sheet-PPGI /Hot Dipped Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords