Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

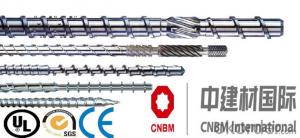

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Technical parament

| model | CMAX-20 | CMAX-30 | CMAX-50 | CMAX-65 | CMAX-72 | CMAX-92 |

| Screw Dia.(mm) | 21.7 | 30 | 50.5 | 62.4 | 71.2 | 91 |

| Rotate.speed(r/min) | 600 | 400 | 400/600 | 500/600 | 400/500 | 400/500 |

| Main Motor(kw) | 4 | 11 | 11/15 | 55/75 | 90/110 | 220/250 |

| L/D | 32-40 | 28-48 | 28-48 | 28-48 | 28-48 | 28-40 |

| Output(kg/h) | 2-10 | 5-30 | 40-80 | 100-300 | 300-600 | 600-1000 |

Application

CMAX series parallel twin screw extruder is widely used for plastic modified granulation ,wood plastic composite granulation ,PVC granulation,PET granulation ect.

Features

It is mainly composed of high torque gearbox,meshed structure screw ,blending feeding system,exhaust system ,heating and cooling system ect.

Advantages

The meshed structure screw has excellent mixing and plasticazation ,comparing with other type extruder.

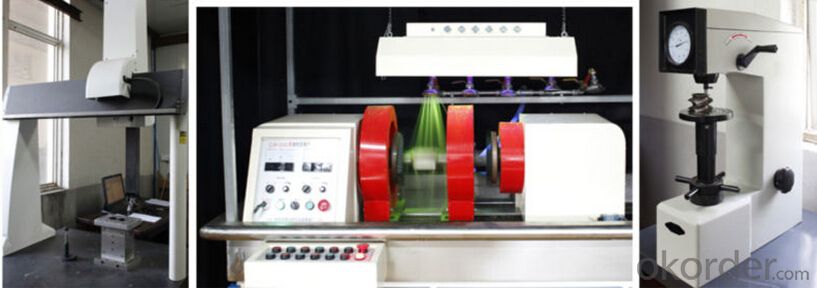

Product show

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: producing polyethylene polypropylene fiber, masterbatch in the dark spot under the light, that is, masterbatch does not change, filter replacement frequently, half an hour... 40The equipment is Changzhou Riyue extruding machine, production of polyethylene polypropylene masterbatch, a dark spot in the light, it is not frequent replacement of masterbatch, filter plugging, half an hour, I added the 30% filling masterbatch, how to solve this problem? Other particles are not wet either. Masterbatch is not turned for help

- 7042, no tax 9350-9400 yuan / ton, 02TN26 no tax,

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q: Is the extruder the same as the extruder?

- Extrusion machine, also called extruder, and is mainly used for power line, power cable, coaxial cable, communication cable, transmission cable, BV type civil line, electronic wire, computer wire, building line, data communication cable, RF cable, HDMI cable, cable, all kinds of high temperature silicone Teflon, core line line, network cable, optical fiber, rubber insulated wire cable wire and cable extrusion wire and cable equipment.

Send your message to us

Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords