Our Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Aluzinc Steel Building Roof Walls

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

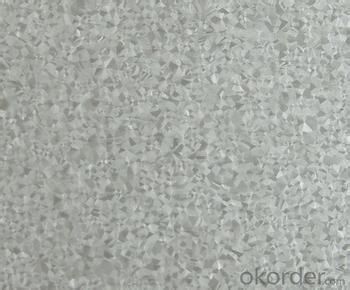

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

2.5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

- Q: I'm sort of a sword maker. You could say I'm an amateur blacksmith. I want to find a dependable source of high-grade steel. I've made a few blades and from what I know about the difference between true steel and cheap steel, I have yet to work with such. All of the metal I have used could not have been true high carbon spring steel because while they are hard, their properties do not reflect that of true steel. I would sincerely appreciate any guidance on where I could order some fine-quality steel so I could produce a truly fine blade.

- Here okorder

- Q: i was thinking like getting a a steel building for 2 or 3 stall does anyone know how much that would cost? Have anyone used steel building how do you like them etc

- a great style of human beings are putting up those steel homes made by making use of agencies like Cleary or Morton because of the fact they are greater fee effective. yet in my opinion, i don't think of they greater wholesome horses all right. They dent very relatively, all the horse has to do is lean against it somewhat. additionally they provide no insulation so as that they are like little ovens interior the summertime and are fairly chilly interior the wintry climate. in case you're able to have adequate money it, i might flow with a competent previous formed timber barn.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: What are the different steel coil specifications?

- The different steel coil specifications refer to the various parameters and characteristics that define a steel coil. These specifications include dimensions such as thickness, width, and length, as well as the type of steel used, coating or finish, and the industry standards it complies with. Other specifications may include tensile strength, yield strength, and chemical composition, which determine the coil's suitability for specific applications.

- Q: I am getting a barn soon and I was debating between wood, and steel. I think steel would look nicer [painted of course] and I was wondering which is cheaper. Any extra info would be great. Thanks x

- Steel barns are much cheaper, but do require more insulation (they get extremely hot in summer and extremely cold in winter w/o insulation), and they have little to no maintinence. in my opinion though, a better-built wood barn is by far the better choice in the long run. They are much more sturdy, more visually appealing (to me), and if kept up well, will last much longer than a steel barn will. I also like that with a wood barn, during rain/hail/etc.etc. you don't have a deafening clatter that is unavoidable with steel barns.

- Q: How are steel coils used in the production of electrical transmission towers?

- Various methods are employed in utilizing steel coils for the manufacturing of electrical transmission towers. Firstly, these coils are frequently employed in the production of the towers' structural components, including the main support columns and crossarms. To effectively bear the weight and strain of the transmission lines, these components necessitate strength and long-lasting durability, which steel coils aptly provide. Furthermore, steel coils are also instrumental in the creation of brackets and braces that reinforce the transmission towers. These particular elements contribute to the even distribution of the load and offer supplementary support to the structure. Steel coils can be molded and welded with ease, rendering them well-suited for the intricate fabrication of these components. Additionally, steel coils find extensive application in the construction of the foundation and anchor bolts that secure the transmission towers to the ground. It is vital for these bolts to possess robustness and resistance to corrosion, as they play a pivotal role in upholding the stability and integrity of the entire tower structure. To enhance their longevity and prevent rusting, steel coils are often subjected to galvanization or other protective coatings. In summary, the indispensability of steel coils in the production of electrical transmission towers arises from their exceptional strength, durability, and versatility. These coils enable the construction of robust tower structures capable of supporting the weight of transmission lines and withstanding diverse environmental conditions.

- Q: How do steel coil manufacturers ensure product quality?

- Steel coil manufacturers ensure product quality through several methods: 1. Quality Control: They implement rigorous quality control measures at every stage of the production process, from sourcing raw materials to final inspection. This includes regular testing, sampling, and monitoring to ensure the coils meet the required specifications and standards. 2. Advanced Technology: Manufacturers utilize cutting-edge technology and modern equipment for the production of steel coils. This helps in maintaining consistency, precision, and accuracy in the manufacturing process, leading to high-quality products. 3. Skilled Workforce: Trained and skilled professionals oversee the entire manufacturing process, ensuring that each step is executed with precision. They are responsible for monitoring, analyzing, and addressing any potential quality issues, thereby upholding the product's quality standards. 4. Compliance with Standards: Steel coil manufacturers follow industry-specific quality standards and regulations. They ensure that their manufacturing processes comply with internationally recognized standards, such as ISO 9001, to guarantee the quality and reliability of their products. 5. Regular Inspections: Manufacturers conduct regular inspections and audits to assess the quality of their steel coils. This includes both in-house inspections and third-party inspections to ensure an unbiased evaluation of the product's quality. By implementing these measures, steel coil manufacturers consistently deliver high-quality products that meet customer requirements and industry standards.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- That particular exercise will develop the buttock muscles, or the gluteous maximus. In other words, your butt, sometimes referred to as buns, along with many other euphemisms.

- Q: Monopolistic competition means all of their products are identical like things in supermarket like milk. There are no high barriers to entry. Oil and steel are all same in all industries.

- That okorder /

Send your message to us

Our Cheap Hot-dip Aluzinc Steel Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords