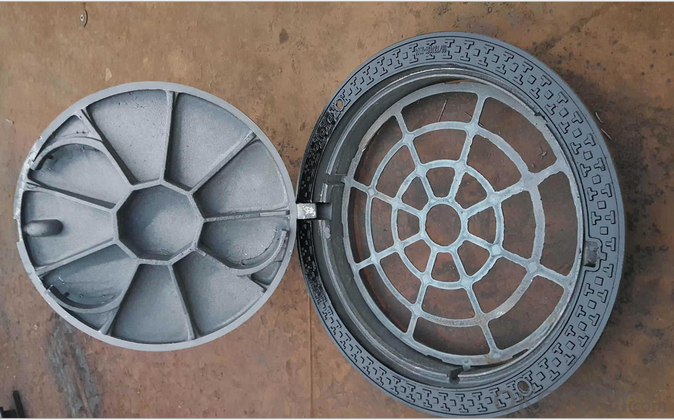

OEM 75 mm cast ductile iron manhole covers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Designs: based on EN124 standard and according to customer's drawing or samples.

2) Color: black, Grey, green, blue and Marble , etc.

3) Applications: water supply and drainage, fire engineering, natural

4) Inspection: in-house or the third party as per customer's request.

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| D80 | D400 | 700*700 | 800*800 | 100 | 92 |

| D70 | D400 | 600*600 | 703*703 | 100 | 77 |

1. Light weight,Anti-corrosive

2. High pressure endurance

3. Easy to install and open

4. Long and steady service

Ductile Iron manhole cover & grating features:

1. High strength:The tensile strength of ductile iron is more than 420Mpa and the yield strength is more than 300MPa, three times more than gray iron.

2. Good toughness: impact value is similar to carbon steel and 10 times than grey iron.

3. Good plasticity. Elongation of ductile is more than 7% which is similar with high-carbon steel, gray iron material and extend rate is zero.

4. Anti-corrosion resistance: The corrosion was only 0.25 times of pipes during ninety days spray corrosion test and 0.1 times of gray iron pipes. The life is 2 times longer than gray iron pipes and 5 times longer than ordinary steel pipe.

5. Applied In most municipal applications: water, salt water, steam, the corrosion resistance and oxidation resistance of cast iron are more than steel. Because of the spherical graphite cast iron microstructure, ductile iron does better than steel in reduced vibration capacity.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q: What are the factors affecting the machining process of the casting material and structure?

- Medium carbon steel begins, and the casting can not be punched and tapped directlyStainless steel, ordinary grade (Fe based alloy element content, less) can not do heat treatment. But processing small holes or tapping to heat treatment (solution. In practice, the annealing treatment can also be). There are a lot of stainless steel matrix is not to say, for example, nickel, cobalt and tungsten. And so on.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q: What should I pay attention to when designing a casting structure?

- (2) in the prevention of metal mold casting misrun and cold partition should pay attention to the following problems: the structure of A casting thickness should be appropriate not too thin, especially when casting size when not too thin; the B should avoid a big level, because it makes the liquid metal in the casting. Rise slowly, and the air contact surface, easy oxidation, and because the metal type liquid metal heat quickly, quickly lose liquidity, easy to cause misrun and cold lap, slag and other defects; C casting shape should be streamlined to avoid sharp corners and has sharp change connection structure in order to facilitate the flow of liquid metal. 2 in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Even distribution is a good thing. Generally, the machining allowance of the casting is uneven.If the processing depends on how your processing techniques have been arranged.In the NC milling plane contour machining, when the rough margin is large, how to deal with.1. Return to the foundry, too large margin improvement.2. Then you can spend more time on it.

Send your message to us

OEM 75 mm cast ductile iron manhole covers

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches