Non-Woven Polypropylene Geotextile Fabric Reinforcement Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Polyester Nonwoven Geotextile:

The non woven geotextiles are made by non-woven process technology, selects polyester staple fiber with high monofilament strength and excellent thickness ratio as raw material after underwent adequate scutching.

The state-of-the-art high speed needle punching production line is adopted, its roll width is up to 8meters.

Main Features of Polyester Nonwoven Geotextile:

It is of excellent physical and hydraulic properties, and especially its advantages in the tensile strength,

longitudinal and lateral strength ratio, uniformity and so on.

Supply a wide range of color, such as white, green and grey. Independent developed soft green fiber can

protect installer’s eyes at the onsite during work under the strong light, and it is eco-friendly productions.

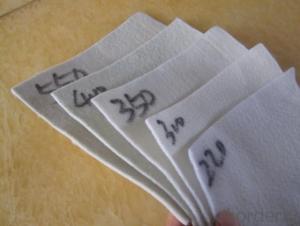

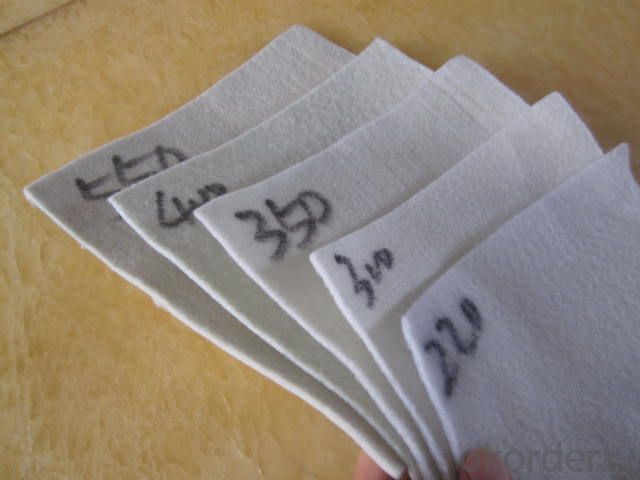

Specifications of Polyester Nonwoven Geotextile:

200g/m2, 250g/m2, 300g/m2, 350g/m2, 400g/m2, 450g/m2, 500g/m2, 600g/m2, 800g/m2

1.woven geotextile(reinforced geotextile)

2.Materials:PP

3.Tensile strength:15~100kn/m

4.Unit weight:100~400g/m2

5.Width:1 ~ 6m

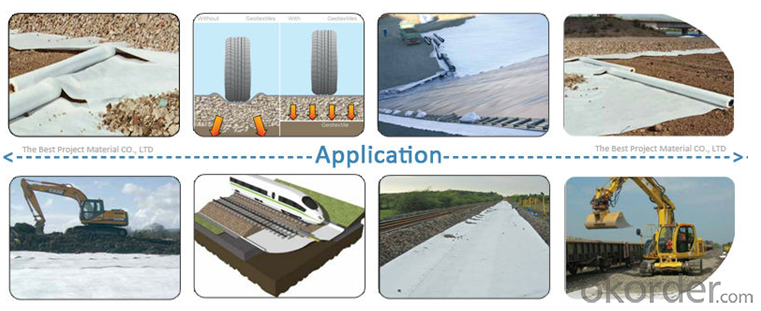

Applications of Polyester Nonwoven Geotextile:

Used in many civil engineering and building applications. Designed to offer filtration, separation, and ersion control functions.

Application industry

Some commen uses of the material includes the following:

1.Road stabilization applications

2.Roofs

3.Civil applications

4.Railway work

5.Landfill lining

6.Trenches

7.Dams

8.Fitration under rip rap and rocks

9.Environmental applications

IMages of Polyester Nonwoven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are geotextiles effective in preventing soil contamination?

- Yes, geotextiles are effective in preventing soil contamination. They act as a protective barrier between the soil and potential contaminants, such as pollutants or invasive species. Geotextiles help to filter and separate different soil layers, preventing the migration of harmful substances and maintaining the integrity of the soil. Additionally, they can aid in soil stabilization and erosion control, further reducing the risk of contamination.

- Q: Alteration of highway seepage control geotextile is generally placed in what position

- Apply to the grassroots level of water defense, the use of embedded, covered with thickness should not be less than 30CM, soil to be solid, to avoid uneven subsidence, cracks. Lap width should be greater than 15CM.

- Q: Geotextile how to sampling

- With special equipment, you can contact the company.

- Q: Can geotextiles be used in mining reclamation projects?

- Yes, geotextiles can be used in mining reclamation projects. Geotextiles are commonly used in mining reclamation to control erosion, stabilize slopes, and promote vegetation growth. They can also help in containing and filtering pollutants from mining sites, preventing soil and water contamination.

- Q: What are the different geotextile reinforcement techniques?

- There are several different geotextile reinforcement techniques, including mechanical methods such as soil nails, ground anchors, and geogrids, as well as chemical methods like soil stabilization using polymers or cement additives. Additionally, techniques such as soil wrapping, slope terracing, and retaining walls can also be used to provide geotextile reinforcement in various applications.

- Q: What are the factors that affect the strength of geotextiles?

- The factors that affect the strength of geotextiles include the type and quality of the materials used in their production, the manufacturing process, the density and thickness of the fabric, the presence of any additional reinforcement layers, the level of UV stabilization, and the environmental conditions in which they are used.

- Q: What are the advantages of using geotextiles?

- Geotextiles offer several advantages such as soil stabilization, erosion control, filtration, and drainage, which can enhance the overall performance and longevity of civil engineering projects. They provide a cost-effective solution by reducing the need for extensive excavation, improving load-bearing capacity, and minimizing long-term maintenance requirements. Additionally, geotextiles are environmentally friendly, allowing water and air circulation while preventing soil erosion, thereby promoting sustainable development and conservation of natural resources.

- Q: Concrete pavement or geotextile

- Do not add, with the asphalt Ma plug Seal if you have to choose the best choice for geotextile waterproof the best

- Q: Geotextile need to adjust the humidity before sampling, what does this mean

- probably. For the first time I heard that geotextiles were sampled to be wet.

- Q: What are the different geotextile installation guidelines?

- The different geotextile installation guidelines include proper site preparation, ensuring the soil is smooth and free of debris, anchoring the geotextile securely to prevent movement, overlapping the geotextile to ensure complete coverage, and using appropriate techniques for joining and sealing the geotextile. Additionally, it is crucial to follow manufacturer instructions and consult with an engineer for specific project requirements.

Send your message to us

Non-Woven Polypropylene Geotextile Fabric Reinforcement Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords