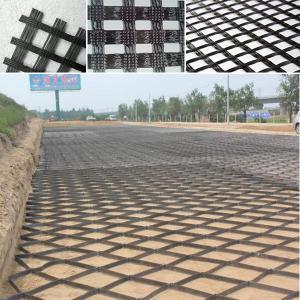

Biaxial Geogrids Non Woven Geotextile Bag PET High Strength Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile Bag

Product Description of Non Woven Geotextile Bag PET High Strength Quality

Made by polyester (PET) or polypropylene (PP) fiber as the raw material, making double sides ironed and pressed needle-punched non-woven geotextile through the spun bonded technology, and then processed to bag with specified dimension, fill soil, sand and fertilizer etc. padding into bag according to local soil conditions and scientific proportion, and then spray seeds which are suitable for local climate, form a new product which could restore or create a new ecosystem.

Specification Non Woven Geotextile Bag PET High Strength Quality:

Greige cloth for ecological bag is 150~180 GSM, the physical dimension for ecological bag will be determined based upon the project requirement.

Property Non Woven Geotextile Bag PET High Strength Quality:

1. With the advantages of anti-UV, anti-aging, non-toxic, no combustion-supporting, bag rip no stretch;

2. Bags are soft with good integral, permeability is strong and scouring resistance, good durable performance;

3. Good plasticity and construction process is simple;

4. Strong corrosion resistance, resistance to microbes, high s oil stability, easy for plant growth;

5. Comprehensive functions of environmental protection, ecological afforestation, soil and water conservation, forming of ecological slope protection system.

Application Non Woven Geotextile Bag PET High Strength Quality:

Commonly used in barren hills, mining repair, highway and railway slope greening, riverbanks slope protection, inland waterway improvement etc. projects.

Packaging & Shipping

Items per Carton: 50 Pieces/Pack

Package Measurements: 50X45X120 cm

Gross Weight: 50.0 kg

Package Type: 50bags in one package or as request

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are often used to stabilize soil and prevent erosion in underwater environments such as riverbanks, shorelines, and underwater slopes. Geogrids are designed to withstand the hydraulic forces of water and provide long-term stability in these challenging conditions.

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by enhancing the stability and strength of the base and subgrade layers. They distribute the load more evenly, reducing the stress on the pavement structure. Additionally, geogrids prevent the lateral movement of soil particles, improving the overall performance and lifespan of the road.

- Q: Basic introduction of fiberglass geogrid

- Fiberglass geogrid is glass fiber as the material, the reticular structure material of the knitting process, for the protection of glass fiber, improve the overall performance of geo composites through a special coating treatment process and the.

- Q: Can geogrids be used in green wall systems?

- Yes, geogrids can be used in green wall systems. Geogrids provide stability and reinforcement to the structure, helping to support the weight of the green wall system and prevent soil erosion. They can be used to create a strong foundation and provide additional support for the plants, ensuring the success and longevity of the green wall.

- Q: How do geogrids improve the performance of geosynthetic filters?

- Geogrids improve the performance of geosynthetic filters by providing additional reinforcement and stability to the filter system. They enhance the tensile strength and load distribution capabilities of the filter, preventing soil erosion and maintaining the integrity of the filtration system. Additionally, geogrids help to reduce pore clogging and increase the overall longevity and efficiency of the geosynthetic filter.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both types of geosynthetics used in civil engineering, but they differ in terms of composition, function, and application. Geogrids are typically made of high-strength polymer materials, such as polyester or polypropylene, and are designed to provide reinforcement and stabilization to soil or aggregate layers. They have a grid-like structure with open apertures that allow for soil interlocking, enhancing the load-bearing capacity of the soil. Geogrids are commonly used in applications such as retaining walls, road construction, and erosion control. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of natural sodium bentonite clay sandwiched between two geotextile layers. The clay layer acts as a hydraulic barrier, providing excellent seepage control and preventing the migration of liquids or gases. GCLs are often employed in environmental containment systems, such as landfill liners or caps, and in other applications that require effective containment of fluids. In summary, while geogrids primarily focus on reinforcement and stabilization of soil, geosynthetic clay liners specialize in seepage control and containment. Their differing compositions and functions make them suitable for distinct engineering purposes.

- Q: Geogrid test items: what is the point of the joint point?

- Because geomembrane or waterproof plate in the actual construction of the project often need to overlap, that is, the edge stitching, and then use a welding machine to weld into one, to prevent water penetration

- Q: What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it can significantly impact the mechanical properties and performance of the geogrid. At higher strain rates, the geogrid may exhibit increased stiffness and strength due to the rate-dependent nature of its materials. This means that the geogrid can better resist deformations and provide enhanced stability under dynamic loading conditions. However, at extremely high strain rates, the geogrid may experience reduced performance and even failure due to excessive stress concentrations and insufficient time for dissipation of energy. Thus, understanding and considering the strain rate is crucial in designing and applying geogrids for different applications.

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are often used to provide additional strength and stability to the surrounding soil, which can help prevent pipeline movement or damage due to settlement or external loads. By distributing the load more evenly and reducing stress on the pipeline, geogrids can enhance the overall performance and longevity of underground pipeline systems.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments. Geogrids are commonly used to enhance the stability and strength of soil structures, including bridge abutments. They provide lateral reinforcement, reduce settlement, and improve overall performance by distributing loads more evenly.

Send your message to us

Biaxial Geogrids Non Woven Geotextile Bag PET High Strength Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords