Qué Es Geotextil - Non-Woven Fabric Geotextile with High Stabilization and Low Price for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

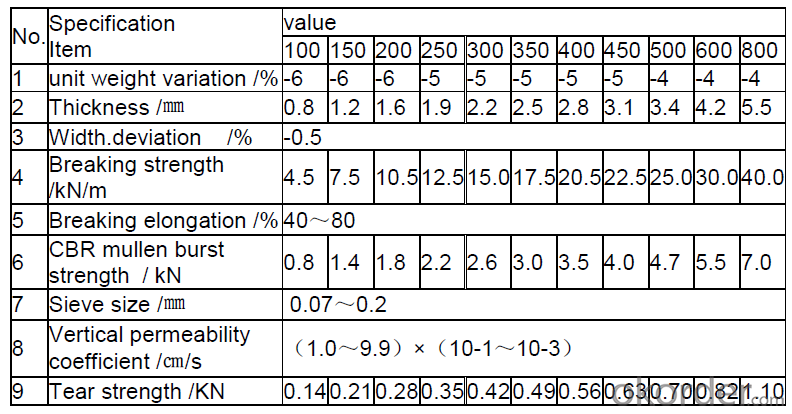

Specification

Description

CMAX's civil nonwoven fabrics are produced using the latest technology in geotextile

manufacturing. Comprised of high strength polypropylene fiber, CMAX's complete line of

needle punched nonwovens provides superior performance in applications of filtration,

separation, drainage and erosion protection.

Benefits

Durable, chemical resistant UV stabilized polypropylene fibers

High tensile strength, with excellent puncture and tear resistance

NW structure provides excellent surface friction and built in elongation

Chemically stable for use in aggressive environments

Fine pore structure and high permittivity

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q: Can geotextiles be used in the construction of reservoirs?

- Yes, geotextiles can be used in the construction of reservoirs. Geotextiles are commonly used in civil engineering projects, including reservoir construction, to provide filtration, separation, and reinforcement. They can be used to prevent soil erosion, stabilize slopes, and enhance the overall performance and longevity of reservoir structures.

- Q: What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q: What are the specifications for geotextiles in pond liner projects?

- The specifications for geotextiles in pond liner projects can vary depending on the specific requirements of the project. However, common specifications may include factors such as the desired strength, permeability, and durability of the geotextile material. Additionally, the specifications may also consider the desired weight, thickness, and UV resistance of the geotextile. Ultimately, these specifications are determined based on the specific needs and conditions of the pond liner project.

- Q: Hope expert expert to give the answer

- The ditch is the ditch at the edge of the roadbed, mainly used to collect and exclude a small amount of surface water within the roadbed and flow to the roadbed; drainage ditch is the ditch, cut ditch, roadbed near the water discharged to the bridge or road Where the ditch in the natural river ditch. Geotextile is a kind of synthetic high strength fiber material which is used to improve the bearing capacity of subgrade when the bearing capacity of the foundation is poor. It has many kinds of fiber materials. The purpose is to improve the bearing capacity and prevent the cracks in the road surface.

- Q: 300 grams per square meter of anti-geotextile there? what price

- Hello, 300 grams of geotextile with less, the best near the purchase of the specific price of the price can be a private letter or telephone I Hua Zhi geotextile material manufacturers for you to answer

- Q: How do geotextiles help with reinforcement of geogrid reinforced embankments?

- Geotextiles help with reinforcement of geogrid reinforced embankments by acting as a separation layer between the soil and the geogrid. They prevent the intermixing of different soil layers, thereby maintaining the stability and integrity of the embankment. Additionally, geotextiles enhance the drainage capabilities of the embankment by allowing water to pass through while retaining the soil particles. This helps in reducing the potential for erosion and maintaining the long-term performance of the embankment.

- Q: What is the effect of tunnel geotextile failure on tunnel quality

- My company specializes in the production of geotechnical materials, treat people with sincerity to ensure your satisfaction.

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer several advantages in green building design. Firstly, they provide effective erosion control by stabilizing soil and preventing sediment runoff. This helps to protect the environment and nearby water bodies. Additionally, geotextiles enhance soil fertility and moisture retention, promoting healthy plant growth and reducing the need for irrigation. They also help in weed suppression, reducing the reliance on herbicides. Moreover, geotextiles can be used to create permeable pavements, allowing rainwater to infiltrate the ground and replenish local groundwater supplies. Overall, the use of geotextiles in green building design improves sustainability, reduces environmental impact, and enhances the overall performance of the project.

- Q: What are the specifications for geotextiles in retaining wall construction?

- The specifications for geotextiles in retaining wall construction typically include factors such as the tensile strength, puncture resistance, and permeability of the material. They should also meet certain standards for durability, UV resistance, and chemical compatibility with the surrounding soil. Additionally, the geotextiles should have appropriate dimensions and weight to provide effective separation, filtration, and reinforcement within the retaining wall system.

- Q: Geotextile geomembrane factory need to record, certificate, inspection report?

- 0534- His highest answer the best

Send your message to us

Qué Es Geotextil - Non-Woven Fabric Geotextile with High Stabilization and Low Price for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords