Non-Halogen Low Smoke Flame-retardant Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

1. Nominal Voltage: 300V.

2. Temperature Range: -100°C to +200°C.

3. Conductor: 30 to 10AWG Tinned Copper.

4. Insulation: FEP.

5. O.D.Allowance: ±0.10mm.

6.Black-Brown-Red-Orange-Yellow-Green-Blue-Purple-Gray-White-Transparent-Yellow/green,etc.

Apply to Household appliance, Illumination & Lighting & Headlamp, electric machines, temperature sensor, Military Series, Metallurgy Chemical series, Motor cars & Ships, Electrical Installation.

2. Product Characteristic:

1. Lighter 30% than ordinary products.(Our products(150±10g/m2) are 30% lighter than ordinary ones(220g/m2)).

2. Thinner 25%. Our products (0.15mm) are 25% thinner than ordinary ones (0.2-0.22mm)).

3. With good elongation, It can be folded more than 20 times continuously.

4. Soft and smooth around the bag.

3. Product Specification

Property | Unit | Type | |

Thickness | mm | 0.15±0.02 | 0.20±0.02 |

Weight | g/m2 | 150±10 | 200±20 |

Tensile Strength | N/62.5px | >180 | >200 |

Elongation | % | >10 | >10 |

Oxygen Index | % | >50 | >50 |

Temperature Index | ℃ | >450 | >450 |

Smoking Density | ρ | <150 | <15 |

Halogen | % | 0 | 0 |

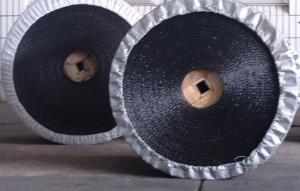

4. Reference Picture

- Q: What material is the packing belt made of?

- The arrangement of methyl groups on the same side of the molecular backbone is called isotactic polypropylene. If the methyl group is arranged in random order on both sides of the backbone, it is called atactic polypropylene, and when the methyl group is arranged alternately on both sides of the backbone, syndiotactic polypropylene is called. In general industrial polypropylene resins, the isotactic structure is about 95% and the remainder is atactic or syndiotactic polypropylene. Industrial products are based on isotactic substances. Polypropylene also includes copolymers of propylene with a small amount of ethylene. Usually translucent, colorless solid, odorless, non-toxic. The melting point can be as high as 167 DEG C because of the highly crystalline structure. Heat resistance and corrosion resistance, products can be steam disinfection is its outstanding advantages. Small density, is the lightest general plastic. The disadvantages are low temperature resistance, low impact and easy aging, but can be overcome by modification.

- Q: Polypropylene packing belt edge why will be scared

- Polypropylene is a thermoplastic resin made by the polymerization of propylene. According to the location of the methyl group into isotactic polypropylene (isotactic, polyprolene), random polypropylene (atactic polypropylene) and syndiotactic polypropylene (syndiotactic, polypropylene) three kinds.

- Q: What's the difference between PP strapping and PET packaging?

- PET packing belt, PP packing belt and steel belt. The following packages are used to analyze the differences between the three packaging belts.

- Q: What's the difference between PP strapping and PET packaging?

- The three kinds of packing belts behave differently in the same environment: the impact resistance and the bending and bending performance of the PET packaging belt are relatively strong, and the PP packing belt is relatively weak

- Q: What is the reason why the packing belt breaks easily?

- When packaging, if packaged with fracture, may be packing machine pulling force is too strong, can adjust the tension knob. If packaged with other normal use, may be a problem with the packing quality, bear tensile strength not too big, you can consider replacing the package. If it is from the joint. Disconnect, may be caused by the following reasons: 1, packing belt is not suitable for the temperature setting, the summer should be at about 450 degrees in winter in the north to about 600 degrees;

- Q: The packer does not have a packing belt

- There is a foreign matter in the extension, and it can not be cleaned and maintained in time. The packing machine is temporarily used. So that the machine has stolen goods inside, so that the belt is not smooth and free, should be more cleaning and maintenance.

- Q: How to identify the quality of a packaging belt?

- Method: the use of lighter smell ignited 3 seconds after blow out, the smell of it, identify it and new material PP difference, one should note that some color toner, smell great, will cover PP (PP renewable materials) part of the taste, don't worry, there's another way.

- Q: What's the difference between a strapping sheet and a steel package?

- Steel band (also known as PET) is a new alternative to steel strapping the international popular band, widely used in iron and steel, aluminum, brick, building materials, chemical fiber cotton, tobacco, paper, metal cans and other industries.

- Q: Plastic packing belt and plastic belt packing the same? What is the difference?

- Plastic packaging belt, also known as PET packaging belt, in plastic packaging belt inside, the intensity is the best, is currently popular in the world instead of steel belt new belt. By virtue of its low cost, beautiful and durable, recycling, high degree of automation, widely used in steel, aluminum, chemical fiber, cotton, tobacco, paper, metal cans and other industries.

- Q: How about the theoretical length of the packing belt?

- The whole set is packaged with a paper tube. If you have to use steel tape, packing tape paper tube diameter measurement, measuring the thickness of the side straps, two data obtained, then add. Is packaged with from the inner circle to an arbitrary side edge length and then put the]. The above, these three data finally obtained and multiplied, and then multiplied by 3.1416, the last is equal to the disc pack how many meters (remember, this formula is only suitable for the disk pack, and the circular disc pack, round the middle part must be hollow

Send your message to us

Non-Halogen Low Smoke Flame-retardant Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords