Flame-retardant High Temperature-resistant Filling Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

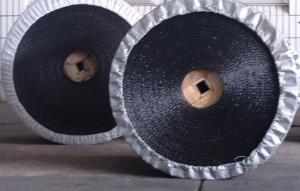

1. Product Description: Flame retardant wire is widely used in the electronics, semiconductor, optoelectronics, optical fiber manufacturing and other industries. 1 the flame retardant wire can effectively eliminate the static electricity caused by the friction on the machine, and avoid the bad influence caused by the static electricity in the printing process. 2 flame retardant rope for new products, it is different from domestic manufacturers use static brush printing, the effect is very significant, 2. Product Characteristic: Simple installation, superior performance, long service life. Especially, it is very suitable for the installation of equipment. Flame retardant rope has good electrical conductivity. Unique performance: the conductive rope is according to the GB12158-90 standard in the 4.1.2 and JT/T407-1999 requirements, Scope of application: tanker, oil tank, powder magazine, oil depots, chemicals warehouse, military warehouse, electronic industry, workplace, mine and so on inflammable and explosive places conductive facilities. Do anti - Electrostatic curtain. 3.Specification : Type Weight(g/m) Tensile Strength (N/20mm,Length) Elongation (%) Long term stability (℃) Melting point (℃) Oxygen Index (%) Φ2 3.80±0.50 ≥50 ≥20 180 268 >30 Φ3 4.20±0.50 ≥70 ≥20 180 268 >30 Φ4 4.90±0.50 ≥120 ≥20 180 268 >30 Φ5 5.30±1.00 ≥150 ≥20 180 268 >30 Φ6 6.20±1.00 ≥300 ≥20 180 268 >30 Φ7 7.10±1.00 ≥330 ≥20 180 268 >30 Φ8 8.10±1.50 ≥400 ≥20 180 268 >30 Φ9 9.20±1.50 ≥450 ≥20 180 268 >30 Φ10 10.80±1.50 ≥500 ≥20 180 268 >30 Φ12 12.30±2.00 ≥550 ≥20 180 268 >30 4. Reference Picture:

- Q: Identification of the quality of the packing belt

- PET plastic steel belt identification: the most important standard (not crisp, is to use clamps will be packaged with the middle of the pack, just sampling clamping, cracking, rupture is the most poor packing belt, lines should have been clear, color should be transparent, with small font size 7 in the package down to see this just clear, packing belt very good.

- Q: How is the packing belt sold?

- Vigorously promote the network marketing, you can direct Baidu search Guangzhou double packing, double steel belt, steel belt manufacturers and so on keywords are related to information, also in some large domestic and international Alibaba such as B2B platform station can be seen double promotion information, let customers easily find you is the marketing of the road, rather than the effort to find customers.

- Q: What's the difference between PP strapping and PET packaging?

- PET packing belt, PP packing belt and steel belt. The following packages are used to analyze the differences between the three packaging belts.

- Q: Identification of PP packaging belt

- PP packaging machine with the general white (other colors should be bright), quality is better, because these are not easy to mix old material.

- Q: Where can I get a tin strap?

- The sheet iron packing belt is also called the galvanized packing belt. You can buy it from a packing material factory.

- Q: Do you have your bags ready before boarding?

- To check the plane's luggage, if the bag, rod boxes do not pack themselves to zip, if it is the case, to do the packaging, fragile to check in to inform, if they do not have to pack, pack at the airport, need to charge 20 yuan fee, if the home has a package their tools can be packaged to trip! Hope to help you ~!

- Q: What is the reason that the packing belt of the packer is not glued?

- Packaging materials with the belt has a bearing, you may have this batch of packaging materials, raw materials doped more ingredients, and now on the market with the main component of polypropylene, commonly known as PP. A better pack should have a PP content of more than 95%. Other ingredients are complex, such as mixing calcium carbonate, talc, wollastonite, glass fiber and other inorganic fillers. If the ingredients are more, the hot-melt viscosity is poor. It is recommended that you provide the supplier with the matching parameters.

- Q: Packing belt

- Packing belt (PP, PET) is divided into PP packing belt (also known as polypropylene packing belt) and PET strap (also called plastic packing belt), respectively using polypropylene and polyester PET for the production of raw materials, which are suitable for different heavy objects need to pack.Atlas of packing belt (4 pieces)Brief description: PP packing belt and PET packing belt are all kinds of plastic environmental protection packing belts which are widely used. PP packaging belt has been produced in China for more than 30 years, and PET belt has been produced in China for more than 20 years.

- Q: Why are packing machines always unstable?

- The voltage of the supply is abnormal.This machine should use 220V voltage. Many factories voltage is often inadequate, if the use of long cable will cause a voltage drop so that the soup temperature becomes lower, even in fastened when burned motor.

- Q: What is the standard of plastic strapping?

- Characteristic(1) strong tensile resistance, both tensile resistance of the steel band, but also the ductility of the impact resistance, but also to ensure the safety of transport products.(2) the elongation is small, the elongation is only 1/6 of the polypropylene band. It can keep the tension for a long time.(3) strong heat resistance, melting point of 260 degrees, 120 degrees below using deformation.(4) good safety, no steel belt rust, contamination of tied objects, bright colors.

Send your message to us

Flame-retardant High Temperature-resistant Filling Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords